Gas piping – PB Heat Gas Boiler User Manual

Page 18

16

GAS PIPING

A . GENERAL

1. All fuel piping to the boiler is to be in accordance

with local codes. In the absence of local regulations

refer to the National Fuel Gas Code, ANSI

Z223.1/NFPA 54.

2. Size and install piping to provide a supply of gas

sufficient to meet the maximum demand of all

appliances supplied by the piping.

B.

FUEL LINE SIZING

1. The rate of gas to be provided to the boiler can be

determined by the following:

Obtain the gas heating value from the gas supplier.

2. As an alternative use Table 4.1 which uses typical

heating values for natural gas and liquefied

petroleum (LP) gas.

3. Table 4.2 shows the maximum flow capacity of

several pipe sizes based on 0.3" of pressure drop.

a. The values shown are based on a gas specific

gravity of 0.60 (Typical for natural gas).

b. Multiply the capacities listed by the factors

indicated in Table 5.3 for gas with a specific

gravity other than 0.60 to obtain the corrected

capacity.

4. The gas piping to the boiler must be a minimum of

3/4" pipe. The boiler is supplied with a 3/4" NPT x

1/2" NPT bell reducer. Do not remove the reducer.

5. Size and install the gas supply piping for no more

than 0.5 inches of water pressure drop between the

gas regulator and the boiler.

C. GAS SUPPLY PIPING INSTALLATION

1. Do not install any piping directly over or in front of

the boiler. Locate the drop pipe adjacent to the

boiler.

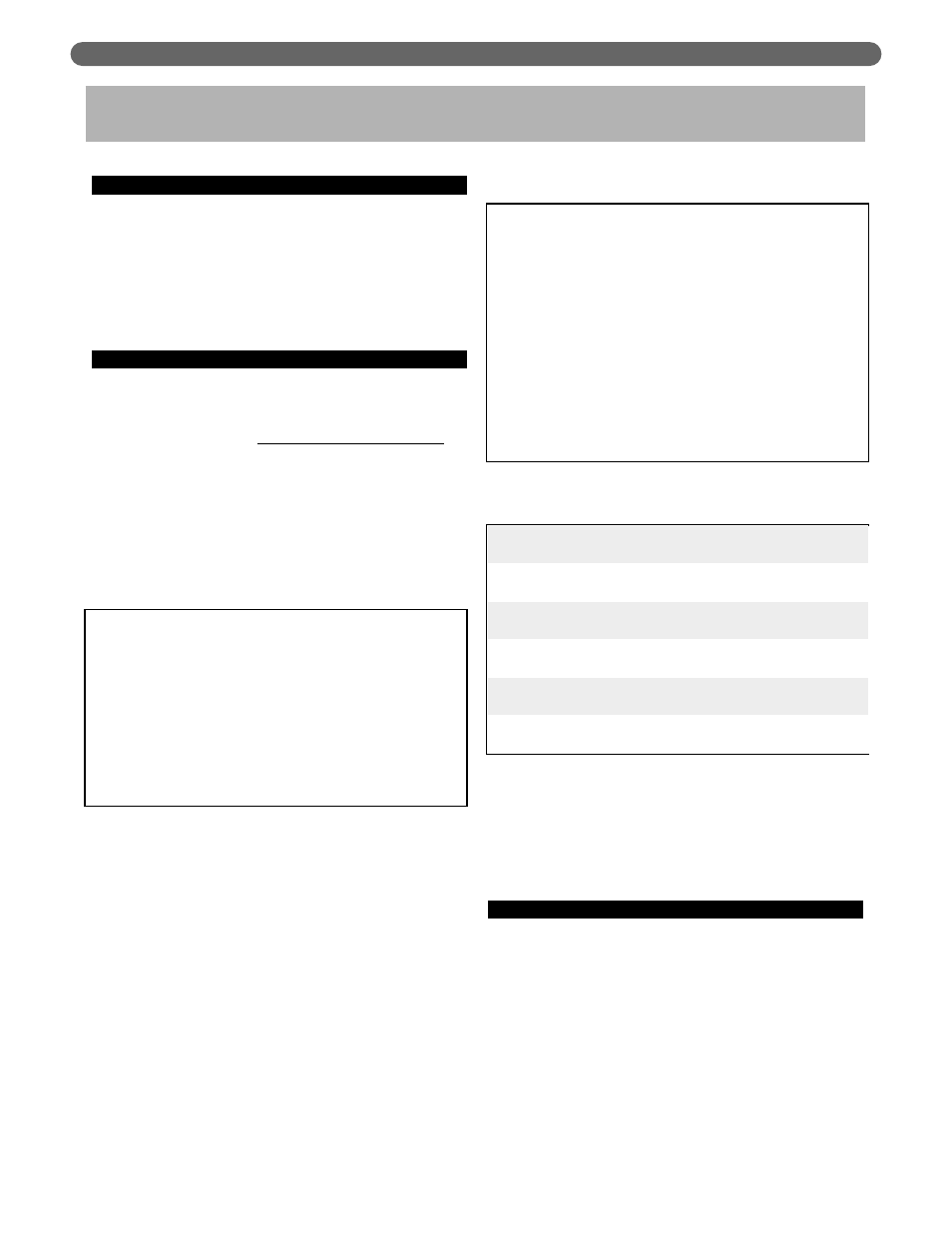

4. GAS PIPING

Boiler Input Rate

Gas Heating Value

Input Rate

(

ft³

/

hr

)

=

(

Btu

/

hr

)

(

Btu

/

ft³

)

Boiler

Model

Gas Input Rate* (ft³/hr)

Natural Gas

LP Gas

PI-T50

50

20

PI-T80

80

32

PI-80

80

32

PI-140

140

56

PI-199

199

79

*Natural gas input rates are based on 1000 Btu/ft³, LP

input rates are based on 2500 Btu/ft³.

Pipe

Length

(Feet)

3/4" NPT

Pipe

1" NPT

Pipe

1-1/4"

NPT

Pipe

1-1/2"

NPT

Pipe

10

278

520

1,050

1,600

20

190

350

730

1,100

30

152

285

590

890

40

130

245

500

760

50

115

215

440

670

60

105

195

400

610

The values are based on a specific gravity of 0.60 (typical

for natural gas). See Table 4.3 for capacity correction

factors for gases with other specific gravities.

Table 4.1: Gas Input Rates

Table 4.2: Maximum Capacity of Pipe (CFH) for a

Pressure Drop of 0.3" of Water

Table 4.3: Maximum Capacity Correction Factors

for Specific Gravity other than 0.60

Specific

Gravity

0.50

0.55

0.60

0.65

0.70

0.75

Correction

Factor

1.10

1.04

1.00

0.96

0.93

0.90

Specific

Gravity

0.80

0.85

0.90

1.00

1.10

1.20

Correction

Factor

0.87

0.84

0.82

0.78

0.74

0.71

Specific

Gravity

1.30

1.40

1.50

1.60

1.70

1.80

Correction

Factor

0.68

0.66

0.63

0.61

0.59

0.58