Hle – linear actuators with timing belt drive – Parker Hannifin 192-510011N7 User Manual

Page 3

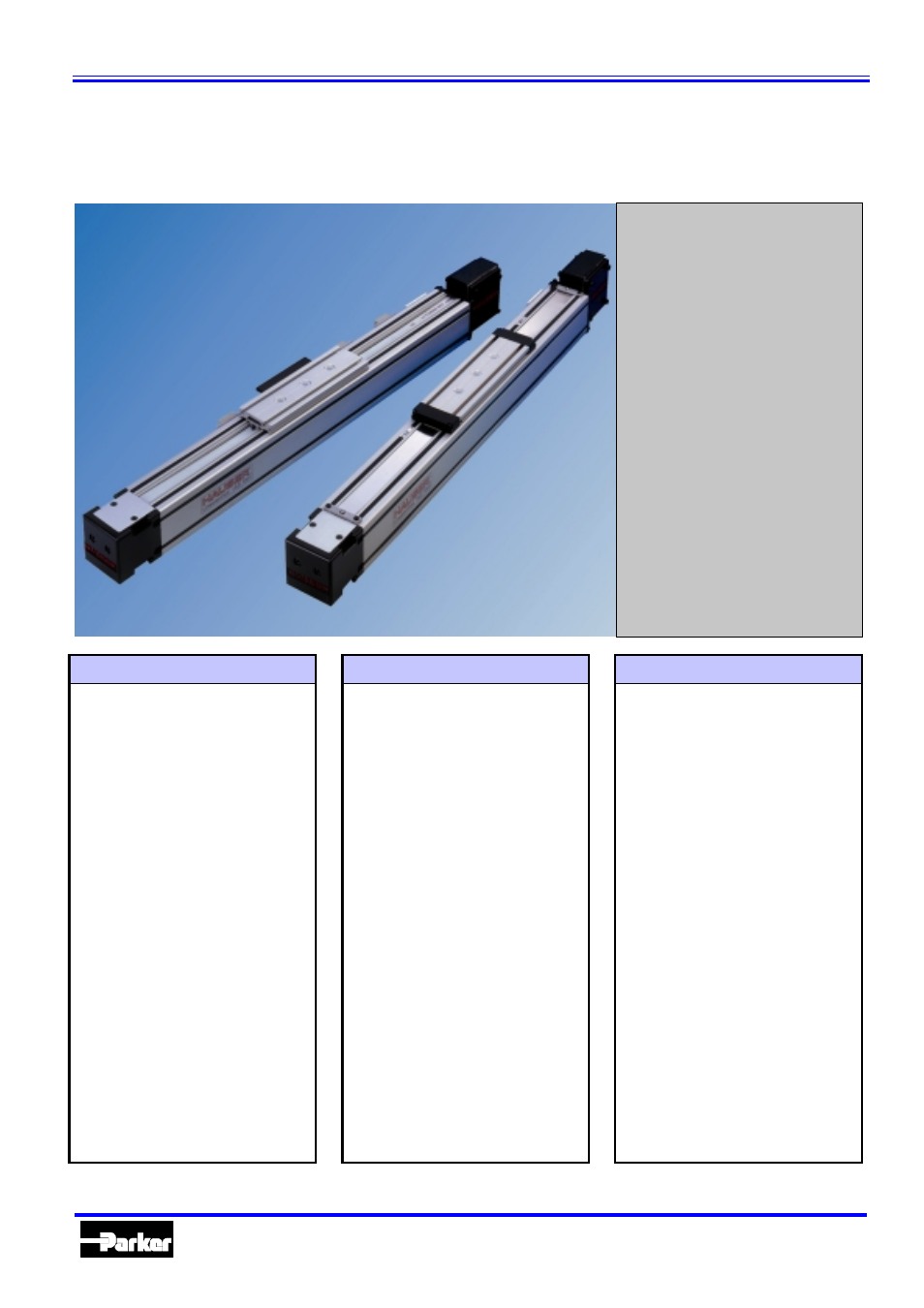

HLE – Linear actuators with timing belt drive

Automation

3

Parker Hannifin GmbH

Electromechanical Division

H L E

l i n e a r a c t u a t o r s w i t h t i m i n g b e l t d r i v e

- f o r g u i d i n g , t r a n s p o r t i n g a n d p o s i t i o n i n g -

Contents:

The HLE - a proven technology.............. 4

Construction of the HLE.......................... 5

Technical data .......................................... 6

Dimensional drawings ............................. 8

HLE 80...................................................... 8

HLE100................................................... 10

HLE 150.................................................. 12

Idler unit................................................. 14

Carriage with bar .................................. 14

Order code ............................................. 15

HLEZ linear actuators with rack-and-

pinion drive............................................. 17

Mechanical accessories ........................ 25

Assembly angle plate ........................... 25

Clamping profile ................................... 26

T-nuts and bolts.................................... 26

Link shaft bearing................................. 27

External buffer stop.............................. 27

Cable carrier.......................................... 28

Longitudinal flange connection set .... 30

Attachment of position sensors .......... 31

Tripping plate........................................ 32

Mechanical limit switch........................ 33

Electrical limit switch ........................... 33

Distribution box .................................... 34

Other accessories and software........... 34

The dynamic linear unit

Typical fields of application

Proven technology

for guiding, transporting and posi-

tioning, even over long distances,

offers:

E

High speeds in practical appli-

cations of up to 7 m/s

E

Up to 108 Nm permitted driv-

ing torque

E

Long travel distances, up to

20 m

E

High load capacity, horizontal

up to 1000 kg /, vertical up to

300 kg

E

Repeatability, up to ±0.05 mm

E

High mechanical efficiency of

95 %

E

Three profile sizes: HLE80,

HLE100 and HLE150, can be

combined in a modular system

E

Simple, rapid installation and

start-up

as part of advanced, cost-effec-

tive construction of machines and

handling systems:

E

Materials handling e.g. pal-

letization, feeding, withdrawal

E

Textile machinery building

e.g. cross-cutting, slitting and

stacking, quilting, seam stitch-

ing

E

Process engineering e.g.

painting, coating, bonding

E

Warehouse technology e.g.

picking, storage

E

Construction e.g. formwork,

placing reinforcing steel

E

Clean room technology e.g.

wafer transport, wafer coating

E

Machine tool building e.g.

loading with workpiece, tool

changing

E

Testing technology e.g.

guiding ultrasonic sensors

proven in numerous applications,

offers the following advantages:

E

Low-friction running guaranteed:

E

Low particle generation (clean

room suitability to class 10)

E

low wear

E

zero maintenance

E

quiet running

E

high efficiency and

E

long service life

E

High dynamic performance

due to low-mass, play-free

wheels

E

Simplified inspection with long

inspection intervals.

E

Longitudinal grooves integra-

ted on all sides of the profile

for mounting attachments or

for use as a cable duct

E

Timing belts can be replaced

without dismantling load at-

tachment plate.

E

Flexible installation options

provided by longitudinal groo-

ves in the load attachment

plate.

Subject to technical modification. Data correct at time of printing

06/99