Accessories for hle and hlez, Automation, Dimensional drawings of connection points – Parker Hannifin 192-510011N7 User Manual

Page 29: Technical data, Guidelines for using cable carriers

Accessories for HLE and HLEZ

Automation

29

Parker Hannifin GmbH

Electromechanical Division

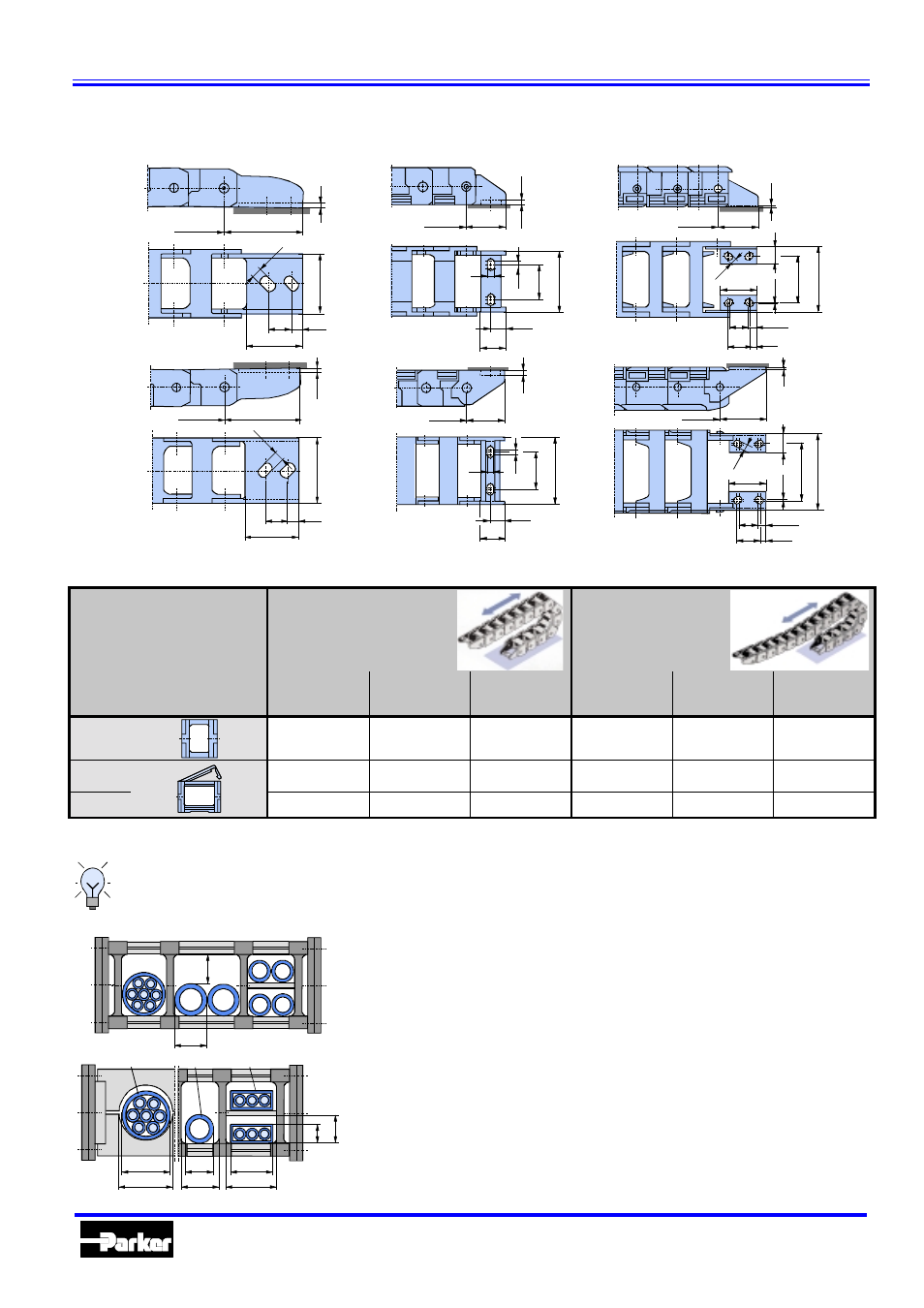

Dimensional drawings of connection points

Type 0320.xx

Type 0450.xx

Type 0625.xx

St

andar

d

f

ix poi

nt

connect

io

n

3

50 (l

1

)

L

K

35

15

7,5

18

,5

7

6

40

L

K

2

A-1

6

A+

9

16

26

7

A: see dimensions

of cable carrier chain

25

94

11

8

9

1,

5

30

35

55

12,5

10

63

2

L

K

St

andar

d

dr

iver

connect

io

n

3

50 (l

1

)

L

K

7

23

35

15

7,5

40

L

K

6

2

A-

13

A+

9

16

26

7

A: see dimensions

of cable carrier

chain

70

2

9

L

K

25

10

0

1,

5

12

3

12,5

10

30

35

55

Technical data

Type

Self supporting arrangement

Self supporting

arrangement with per-

mitted deflection

maximum stroke

[mm]

maximum speed

[m/s]

maximum

acceleration

[m/s

2

]

maximum

stroke

[mm]

maximum speed

[m/s]

maximum

acceleration

[m/s

2

]

0.320

2400

10

10

3500

2.5

1

0.450

3000

10

10

4400

2.5

1

0.625

5000

8

10

6000

3

1

Guidelines for using cable carriers

Use only electrical cables which are suitable for use in cable carriers. Hose lines should be highly flexible and should

only extend slightly under pressure. Weight should be distributed across the cable track as evenly as possible. Cables

must not be twisted when routed in the cable carrier and should be routed next to one another and as loosely as possi-

ble.

d

Avoid laying several lines on top of each other and laying lines of different diame-

ters directly next to one another. If multiple layers must be used, separating strips

should be inserted between each layer – should such circumstances arise, please

contact HAUSER.

If there is no alternative to routing several lines beside each other without sub-di-

visions, the clearance height within the carrier must be less than line diameter.

This is the only way of preventing the cables from twisting.

d

1,1 d

d

1,2 d

d

1,1 d

h

1,

1h

electric line

hose

flat cable

The supply cables must be able to move freely in the cable carrier – they must

never be fastened or bundled together.

Separating strips must always

be inserted

between flat cables routed in multiple layers.

Recommended dimensions of the space required:

with round cables:

approx. 10% of the line diameter

with flat cables:

for each, approx. 10% of the cable width and cable thickness

with hose lines:

approx. 20% of the hose diameter