Porter-Cable PCB370SS User Manual

Page 18

18

RECOMMENDATIONS FOR CUTTING

1. When feeding the workpiece into the blade do not

force the leading edge of the workpiece into the blade

because the blade will deflect, reducing the accuracy

of cut and possibly breaking the blade. Allow the

saw to cut material by guiding the workpiece into the

blade as it cuts.

2. The blade teeth cut material ONLY on the down

stroke.

3. You must guide the wood into the blade slowly

because the teeth of the blade are very small and

they can only remove wood when they are on the

down stroke.

4. There is a learning curve for each person who

wants to use this saw. During that period of time it is

expected that some blades will break until you learn

how to use the saw and receive the greatest benefit

from the blades.

5. Best results are achieved when cutting wood less

than one inch (25.4 mm) thick.

6. When cutting wood thicker than one inch (25.4 mm),

the user must guide the wood very slowly into the

blade and take extra care not to bend or twist the

blade while cutting in order to maximize blade life.

7. Teeth on scroll saw blades wear out and must be

replaced frequently for best cutting results. Scroll

saw blades generally stay sharp for 1/2 to 2 hours of

cutting.

8. To get accurate cuts, be prepared to compensate for

the blade’s tendency to follow the wood grain as you

are cutting.

9. This scroll saw is intended to cut wood or wood

products.

10.When choosing a blade to use with your scroll saw,

consider very fine, narrow blades to scroll cut in thin

wood 1/4 in. (6.4 mm) thick or less. Use wider blades

for thicker materials but this will reduce the ability to

cut tight curves.

11.This saw uses 5 in. (127 mm) long pin or plain end

type blades.

12.Blades wear faster when cutting plywood or particle

board which is very abrasive. Angle cutting in

hardwoods reduces blade tooth set faster due to the

blade deflection.

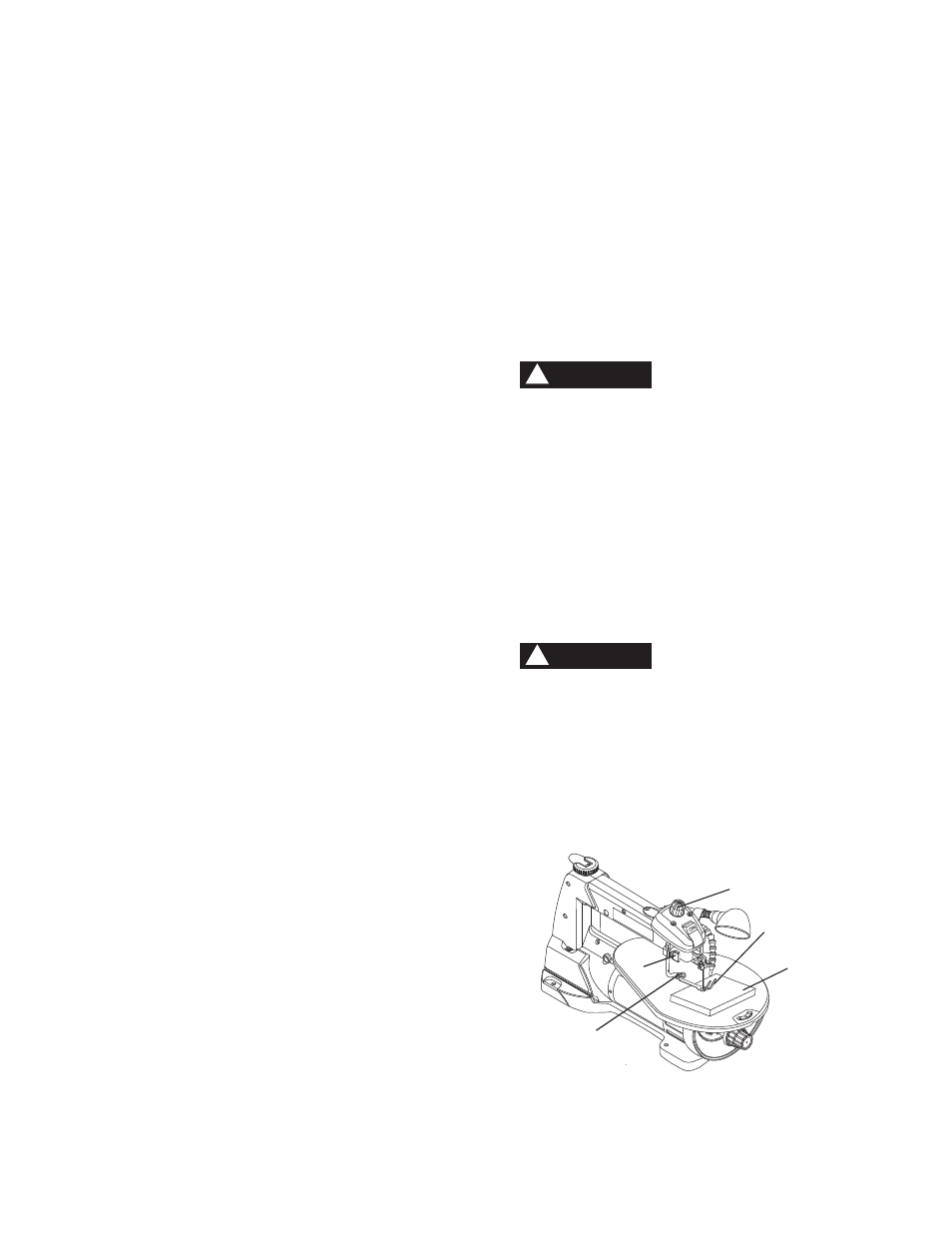

FREEHAND CUTTING (FIG. U)

1. Lay out desired design, or secure design to the

workpiece (1).

2. Raise the blade guard foot (2) by loosening the blade

guard foot lock knob (3).

3. Position the workpiece against the blade and place

the blade guard foot slightly above the top surface of

the workpiece.

4. Secure the blade guard foot (2) by tightening the

blade guard foot lock knob (3).

5. Remove the workpiece from the blade prior to turning

the scroll saw ON. Pull the variable speed control

knob (4) out and set the desired speed by turning the

control knob clockwise or counterclockwise.

CAUTION

!

In order to avoid uncontrollable lifting of the

workpiece and to reduce blade breakage, do not

turn saw ON while the workpiece is against the

blade.

6. When turning the scroll saw ON, position the

workpiece against scrap wood prior to touching the

leading edge of the workpiece against the blade.

NOTE: For your own safety, use the scrap wood

to perform the cutting especially for the small

workpiece.

7. Slowly feed the workpiece into the blade by guiding

and pressing the workpiece down against the table.

CAUTION

!

Do not force the leading edge of the workpiece into

the blade. The blade will deflect, reducing accuracy

of cut, and may break.

8. When the cut is complete, move the trailing edge of

the workpiece beyond the blade guard foot. Turn the

scroll saw OFF.

Fig. U

1

2

4

OF

F

3

9