Assembly, Handwheel assembly, Dust ports – Powermatic DDS-237 User Manual

Page 8: Dust collection, Electrical connections

8

Assembly

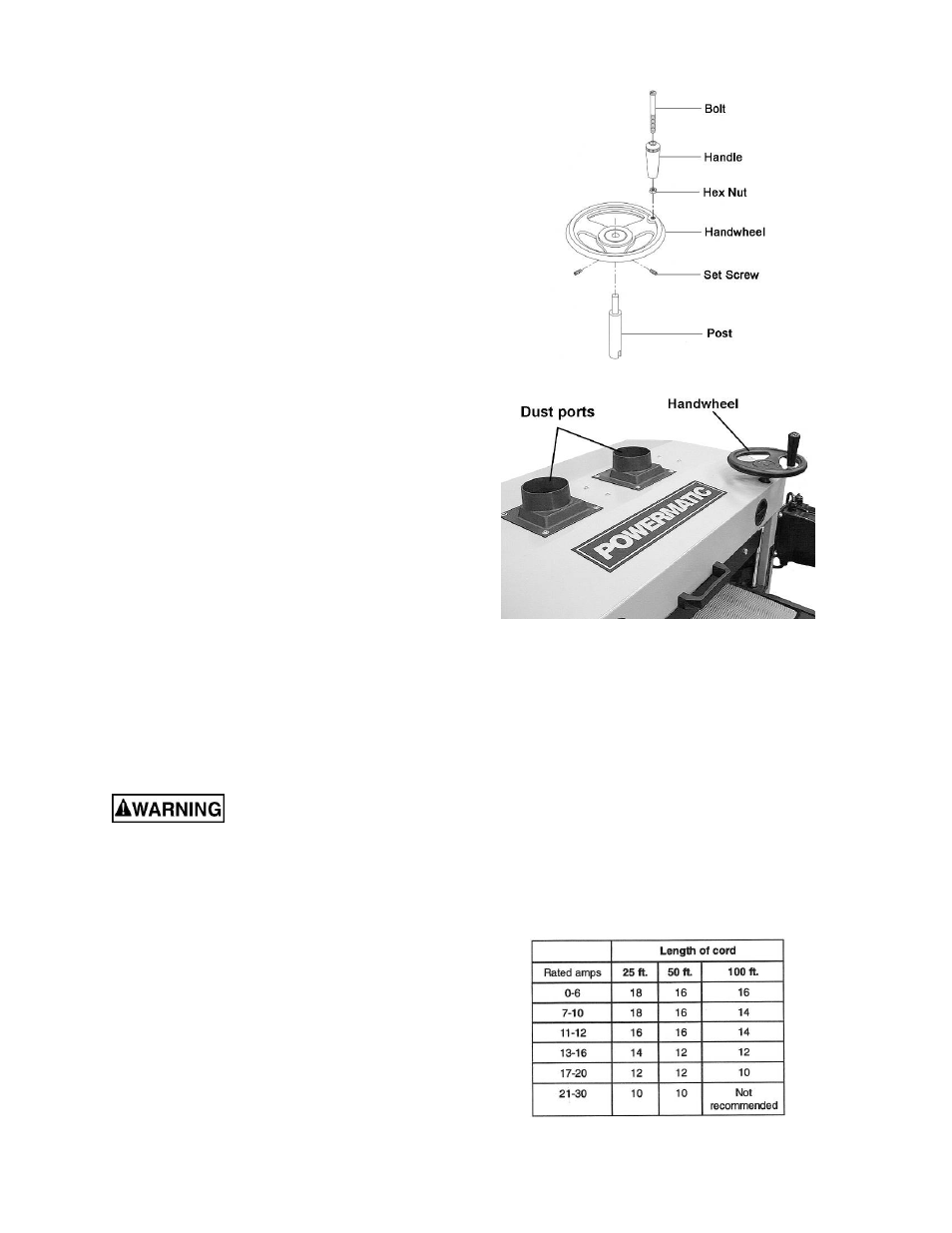

Handwheel Assembly

1. Slide the post up into the handwheel and

secure with the set screws, as shown in Fig 1.

2. Use a flat head screwdriver to screw the bolt of

the handle as far as it will go into the threaded

hole of the handwheel, then tighten the hex nut

down against the handwheel (Fig. 1).

The handle must rotate freely after tightening

the hex nut. If the handle is too tight, loosen

the hex nut and back out the bolt slightly, then

re-tighten the hex nut.

3. The handwheel assembly, used for raising and

lowering the conveyor table, is designed to be

mounted and removed quickly. Set the

handwheel assembly down into the hole of the

hood (Fig. 2) and rotate it until it seats itself

upon the pins of the leadscrew below.

Note: The handwheel must be removed before the

hood can be opened.

Dust Ports

Mount the two dust ports to the top of the hood

with eight 3/16 x 1/2 screws and eight flat washers

(Fig. 2).

Dust Collection

It is strongly recommended that you connect a

proper dust extraction system to the two 4” ports

atop the sander. Make sure the capacity of your

dust collector is at least 1200 CFM.

Electrical Connections

Electrical connections must be

made by a qualified electrician in compliance

with all relevant codes. The machine must be

properly grounded to help prevent electrical

shock and possible fatal injury.

A power plug is not provided with the DDS-225 or

DDS-237 Dual Drum Sander. You may either

connect the proper UL/CSA listed plug or

“hardwire” the machine directly to your electrical

panel provided there is a disconnect near the

machine for the operator. Consult electrical

drawings on pages 39-42 for further clarification of

wiring setup.

This machine must be grounded. Grounding

provides a path of least resistance to help divert

current away from the operator in case of electrical

malfunction. The green wire is the grounding wire.

Figure 1

Figure 2

Make sure the voltage of your power supply

matches the specifications on the motor plate of

the machine.

Extension Cords

The use of an extension cord is not recommended,

but if one is necessary, make sure the cord rating

is suitable for the amperage listed on the

machine's motor plate. An undersize cord will

cause a drop in line voltage resulting in loss of

power and overheating.

The chart in Table 1 shows the correct size cord to

use based on cord length and motor plate amp

rating. If in doubt, use the next heavier gauge. The

smaller the gauge number, the heavier the cord.

Table 1