Powermatic DDS-225 User Manual

Powermatic Grinding machines

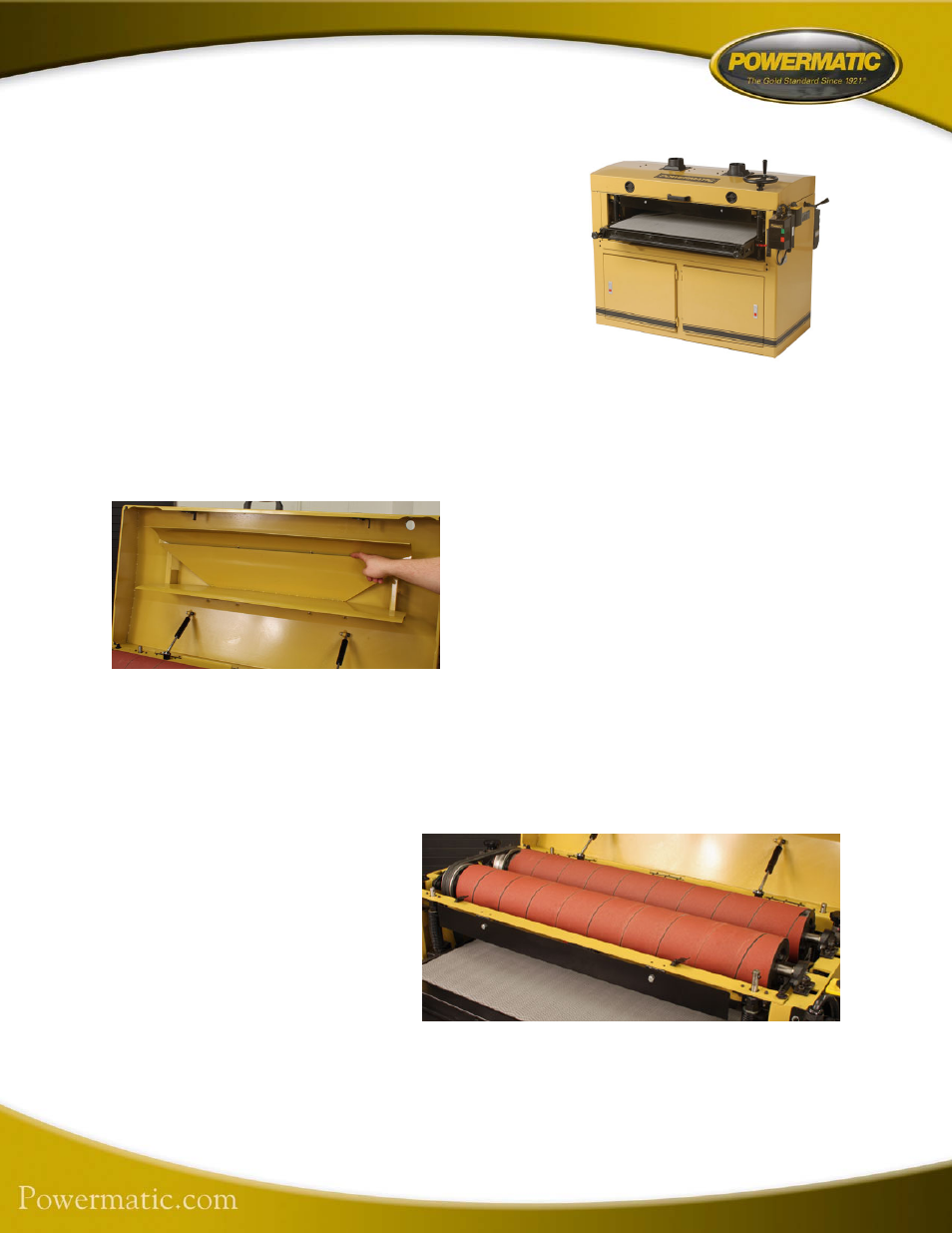

POWERMATIC DDS-225/DDS-237 Dual Drum

Sander

The POWERMATIC DDS-237 Dual Drum

Sander is a very capable solution for your

sanding needs.

The POWERMATIC DDS-237 Dual Drum Sander is a

production class machine that is loaded with features and

available in configurations to suit your needs. The

#1791321 (DDS-237, 37” drums) is equipped with a

10HP, 230/460V (prewired 230V), 3 PH motor. Also

available are the #1791320 (DDS-237 37”-drums) with a

7.5HP, 230V, 1Ph motor and the #1791290 (DDS-225,

25”-drums) powered by a 5HP, 230V, 1Ph motor. All

POWERMATIC Dual Drum Sanders are protected with a

full magnetic On-Off switch. Aside from the 25” drum

length of the DDS-225, the features remain similar.

Size and Capacity

Despite the compact 60”-wide x 45”-deep x 45”-

tall overall size, (DDS-237 model) the

POWERMATIC Dual Drum Sanders have the

capacity to handle a huge range of jobs from

small to large. With a minimum board length of

just 9”, a minimum thickness of 1/32” and

maximum thickness of 5-1/4”, these sanders offer

expansive job coverage.

The top of the cabinet opens for easy access to the drums

and shows the special dust system that helps keep this

machine performing.

Spacious Cabinet

The POWERMATIC Dual Drum Sanders are enclosed in an all-steel cabinet. Compartments

with latching doors at the bottom enclose the motor, drive systems and provide spacious storage.

Removable panels provide good access to important systems when needed.

The full-width, hinged steel top opens

to make working with the drums and

roller systems easy. Built into the top

are a pair of 4”-diameter dust ports.

These ports connect to specially

designed directional baffles within the

top that enhance the effectiveness of

the dust evacuation. For maximum

efficiency, a dust collector system

with a minimum 1200-CFM (cubic

feet per minute) capacity should be

used.

The rubber-covered steel drums enhance accuracy and consistency.