Adjustments, Drum height – Powermatic DDS-237 User Manual

Page 10

10

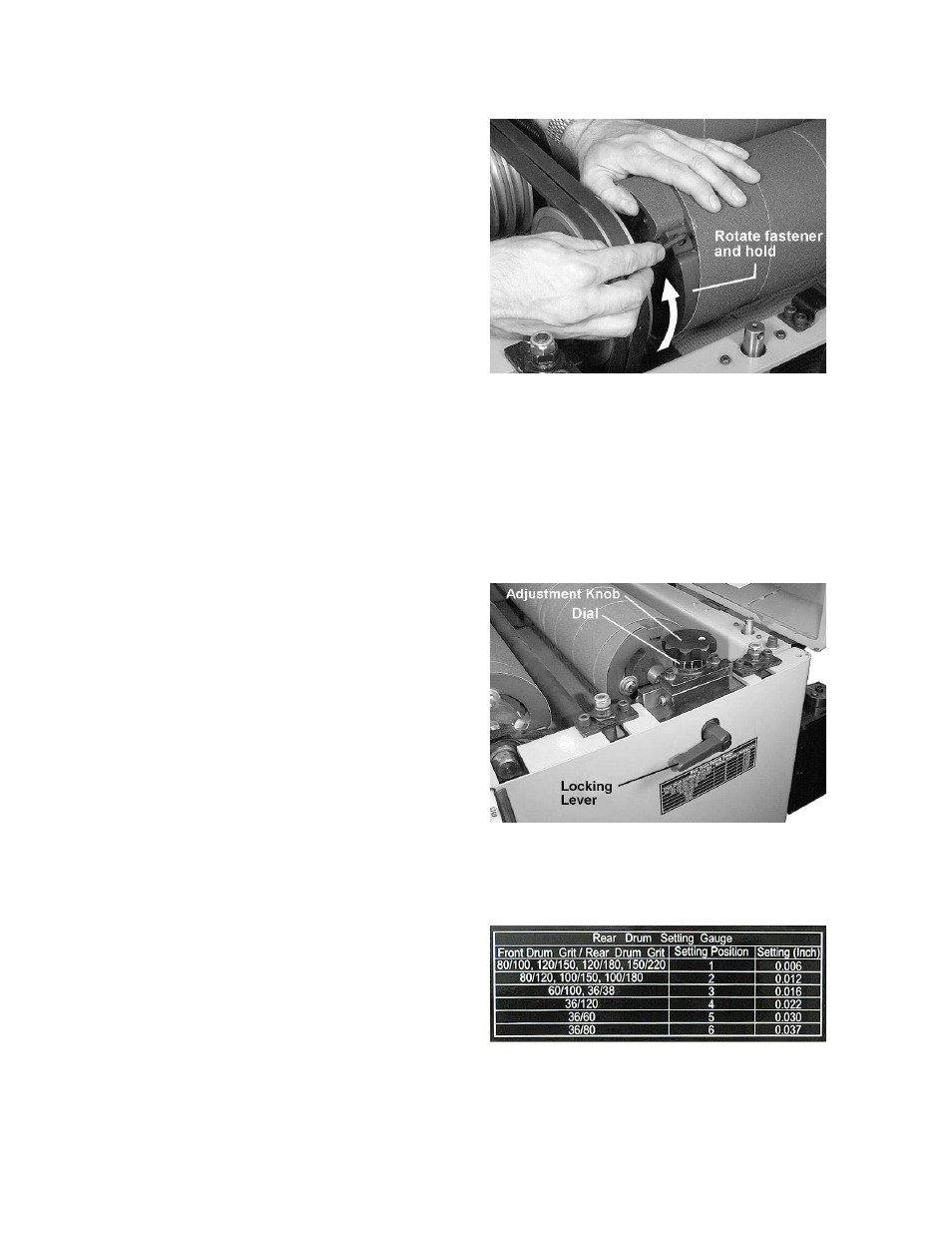

7. The left end of the drum which contains the

recess is an independent piece (Fig. 7) that

can be rotated on the drum. This fastener is

spring-tensioned to take up any slack and hold

the abrasive strip firmly to the drum. Rotate

this fastener backward and hold it there with

your thumb as shown in Fig. 7.

8. Tuck the tapered left end of the strip into the

recess, as shown in Fig. 7, then insert the

locking wedge and socket head cap screw,

tightening the screw until the locking wedge is

firmly seated.

9. Release the spring-tensioned fastener. The

abrasive strip is now ready for use.

10. Repeat this procedure for the other drum.

Adjustments

Drum Height

When using different abrasive grits on the drums,

the height of the drums from the workpiece must

vary. To achieve this, the back drum (which should

always have the finer grit) has been designed for

easy adjustment.

1. Loosen the locking levers (Fig. 8) on both

sides of the machine by rotating them counter-

clockwise.

2. Rotate the adjustment knob to the desired

measurement, using the red triangular

indicator at the base of the dial. A label is

affixed below the locking lever showing the

proper settings. It is also shown in Fig. 9.

3. Repeat this dial setting on the opposite end of

the drum.

Note: It is important that the dial setting be

identical at both ends of the drum.

4. Tighten the locking levers (Fig. 8) by rotating

clockwise, before operating the sander.

Note: The locking levers are spring loaded –

you can move the handle to any position by

pulling out on the lever, rotating it on the hub,

then releasing.

Important: After changing abrasive strips, always

check and, if necessary, reset the back drum

height.

Figure 7

Figure 8

Figure 9