Maintenance, Operations, Basic operation – Powermatic DDS-237 User Manual

Page 15: Stock feeding angle

15

Maintenance

Note: See also Maintenance Checklist on

page 18.

For best results, perform the following proced-

ures on a routine basis:

Grease the four leadscrews on the table.

Lubricate the bushings at each end of the

pressure rollers. Use a dry type lubricant for

this, such as graphite or silicone that will not

attract dust.

Keep the chain below the table clean and

oiled.

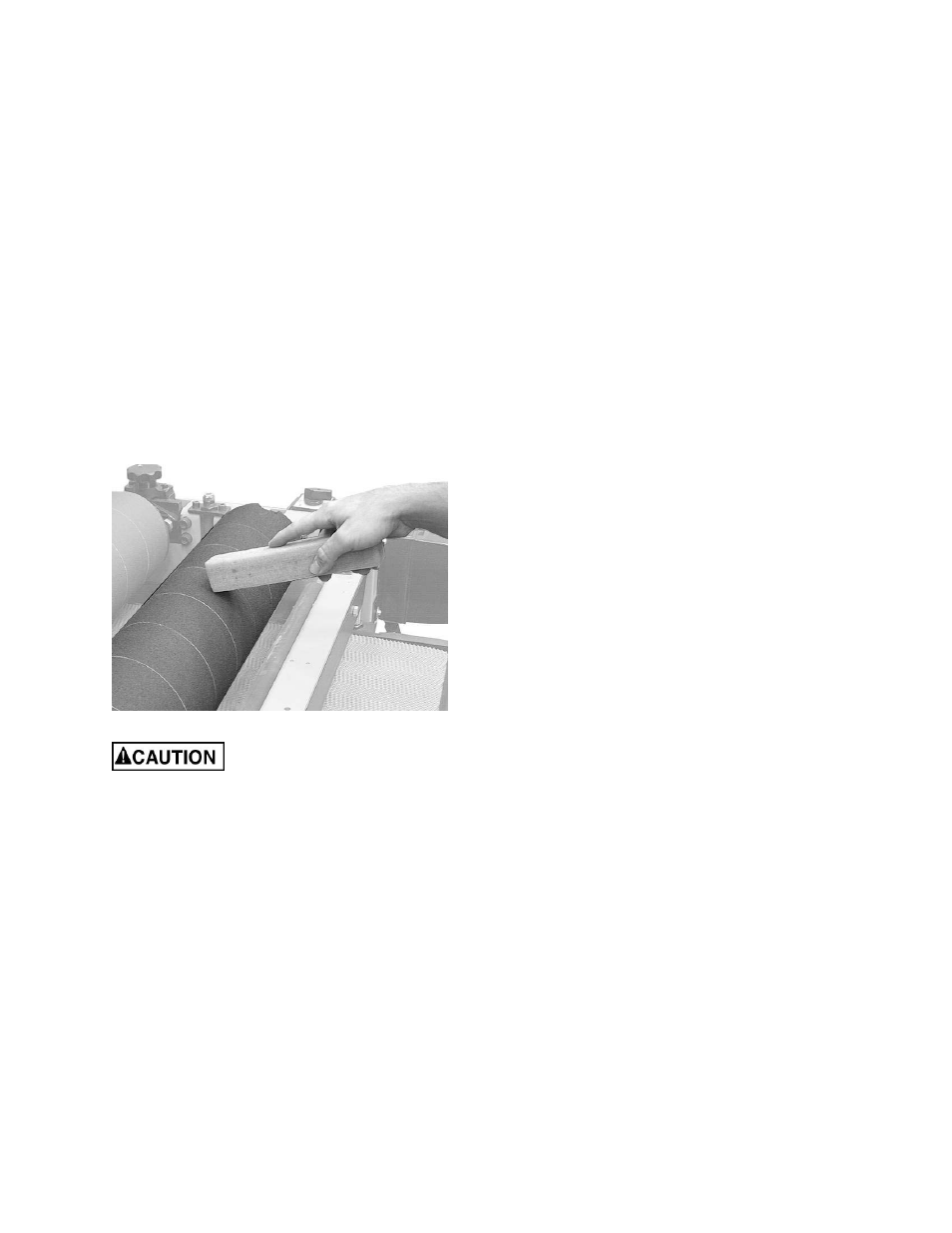

With the machine on and the drums rotating,

clean sawdust from the abrasive strips with

a cleaning stick (Fig. 19). This item is

available as an accessory (stock no.

57620025, JS-1 JET-Stick Belt Cleaner).

Figure 19

Always use eye protection

when performing sandpaper cleaning, and

take precautions to avoid any contact of

hands or clothing with uncovered drums.

After cleaning, use a shop brush to remove

any cleaning stick crumbs from the drums

before resuming sanding operations.

Blow dust from motors and switches.

Check screws, nuts, etc. for tightness.

Check the tension and condition of the belts;

dress with paraffin. (Do not get paraffin on

the abrasive belts.)

Check the oil level in the gearbox by

removing the oil plug on top, and add if

necessary. Use a good quality gear oil. After

every 2,500 hours, completely drain and

refill gearbox.

Operations

Basic Operation

The basic operating procedure for the DDS-225

is as follows:

1. Set depth of cut.

2. Start

drums.

3. Start conveyor and select feed rate.

4. Start dust collector system.

5. Feed stock through unit.

Determining depth of cut is one of the most

important procedures for the sander. It may take

some experimentation to determine the proper

depth of cut, given the variables of abrasive grit,

type of wood, and feed rate. For best results,

use scrap wood to practice sanding and to

develop skill and familiarity with the machine

before doing finish work.

A good rule of thumb when sanding with grits

finer than 80 is to lower the drum so it contacts

the workpiece but drum can still be rotated by

hand. When using grits coarser than 80 grit, you

can lower the drum slightly more. However, a

combination of several variables will determine

the proper depth of cut to use, including the

following:

Abrasive type and grit size.

Width of the piece being processed.

Hardness of the piece.

Feed rate of the conveyor belt.

Stock Feeding Angle

Some pieces, because of their dimensions, will

need to be fed into the machine at a 90º angle

(perpendicular to the drums). However, even a

slight offset angle of the stock will provide for

more effective stock removal. The optimum

feeding angle is about 60º (Fig. 20). Angling the

workpiece for stock removal provides other

advantages, such as less loading of certain

areas of the drums due to glue lines or mineral

streaks in the stock, more even wear of abrasive

strips, potentially faster feed rates, and lighter

loads on the motor.

Note, however, that to get the best final finish

the stock should be fed through the machine so

it will be sanded in line with the grain of the

wood on the final one or two passes.