Start-up procedures – PB Heat MI/MIH series User Manual

Page 28

26

E. CHECKING BURNER INPUT

1. Refer to rating label mounted on the jacket top panel

to obtain the rated BTU per hour input. In no case

shall the input to the boiler exceed the value shown

on the rating label.

2. Check input by use of the following formulas

(PB Heat, LLC suggests reading meter for 2 Cu. Ft.):

U.S. Customary Units

Input (BTU/Hr.)= 3600 x F x H

T

Where:

3600 – Seconds per hour

F – Cubic Feet of Gas Registered on Meter

H – Heat Value of Gas in BTU/Cubic Feet

T – Time in Seconds the Meter is Read

SI Metric Units

Input (kW)= 3600 x F x H

T x 3.6

Where:

3600 – Seconds per hour

3.6 – Megajoule (MJ) per kilowatt hour (kwhr)

F – Cubic Meters of Gas Registered on Meter

H – Heating Value of Gas in MJ/Cubic Meter

T – Time in Seconds the Meter is Read

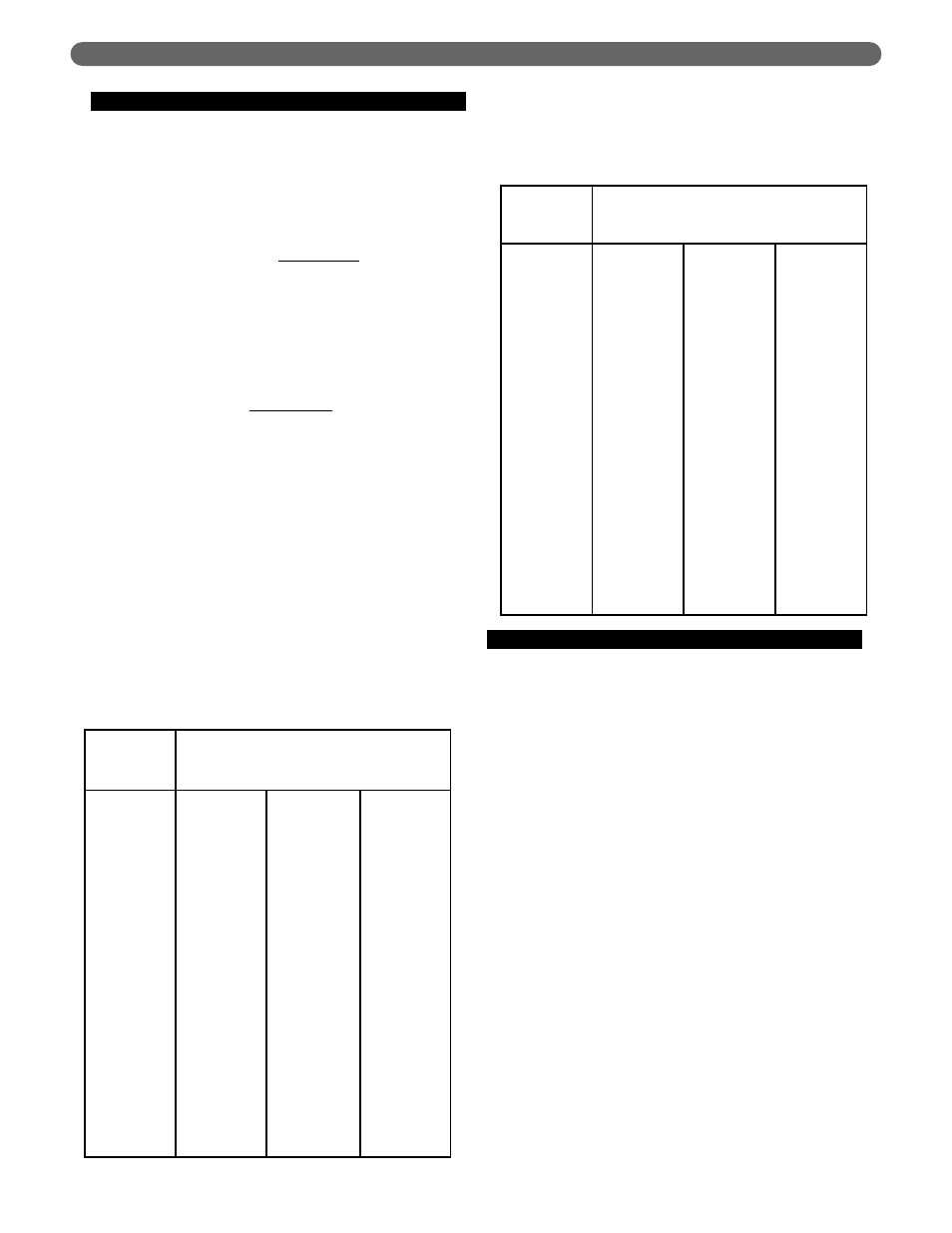

3. As an alternative, use Table 7.1(a) and 7.1(b). Use

the heating value provided by gas supplier. Use a

stopwatch to record the time it takes for 2 cubic feet

(0.0566 cubic meter) of gas to pass through the

meter. Read across and down to determine rate.

Burner inputs in Btu/hr for various meter timings and heat

values. (Table based on 2 cubic feet of gas through meter).

Burner inputs in kW for for various meter timings and

heat values. (Table based on 0.0566 cubic meter of gas

through meter).

F.

CHECK-OUT PROCEDURE

1. After starting the boiler, be certain all controls are

working properly. Check to be sure that the limit will

shut off the boiler in the event of excessive water

temperature. This can be done by lowering the limit

setting until the main burners shut down. When

proper limit function is confirmed, return the dial to

its previous setting.

2. To check operation of the ignition system safety

shut-off features:

a. Standing Pilot:

i)

Turn the gas control knob counterclockwise to

“PILOT”. The main burner should go out

and the pilot should remain lit.

ii) Extinguish the pilot flame. Pilot gas flow

should stop within 2-1/2 minutes. Complete

shutdown is proven since the safety shut-off

valve has stopped main and pilot gas flow.

iii) Reset the boiler by following Lighting

Instructions.

iv) Observe boiler operation through one

complete cycle.

START-UP PROCEDURES

288000

240000

205714

180000

160000

144000

130909

120000

110769

102857

96000

90000

84706

80000

75789

72000

68571

65455

62609

60000

57600

25

30

35

40

45

50

55

60

65

70

75

80

85

90

95

100

105

110

115

120

125

295200

246000

210857

184500

164000

147600

134182

123000

113538

105429

98400

92250

86824

82000

77684

73800

70286

67091

64174

61500

59040

302400

252000

216000

189000

168000

151200

137455

126000

116308

108000

100800

94500

88941

84000

79579

75600

72000

68727

65739

63000

60480

Heat Value of Gas

(Btu/cubic foot)

1000

1025

1050

Time that

meter is

read (sec)

Table 7.1a: Meter Conversion – Natural Gas

(U.S. Customary Units)

Time that

meter is

read (sec)

Heat Value of Gas

(MJ/cubic meter)

37.26

38.19

39.12

25

30

35

40

45

50

55

60

65

70

75

80

85

90

95

100

105

110

115

120

125

84.36

70.30

60.25

52.72

46.86

42.18

38.34

35.15

32.44

30.13

28.12

26.36

24.81

23.43

22.20

21.09

20.08

19.17

18.34

17.57

16.87

86.46

72.05

61.76

54.04

48.03

43.23

39.30

36.03

33.25

30.88

28.82

27.02

25.43

24.02

22.75

21.62

20.59

19.65

18.80

18.01

17.29

88.57

73.81

63.26

55.35

49.20

44.28

40.26

36.90

34.06

31.63

29.52

27.68

26.05

24.60

23.31

22.14

21.09

20.13

19.25

18.45

17.71

Table 7.1b: Meter Conversion – Natural Gas

(SI Metric Units)