Maintenance – Porter-Cable PCB270TS User Manual

Page 29

– 29 –

MAINTAINING YOUR TABLE SAW

GENERAL MAINTENANCE

For your own safety, turn the switch OFF and

remove the switch key. Remove the plug from

the power source outlet before maintaining or

lubricating your saw.

1. Clean out all sawdust that has accumulated inside

the saw cabinet and the motor.

2. Polish the saw table with an automotive wax to keep

it clean and to make it easier to slide the workpiece.

3. Clean cutting blades with pitch and gum remover.

4. A worn, cut, or damaged power cord should be

replaced immediately.

All electrical or mechanical repairs should be

attempted only by a trained repair technician.

Contact the nearest Porter-Cable Authorized Service

Center for service. Use only identical replacement

parts. Any other parts may create a hazard.

5. Use only mild soap and a damp cloth to clean

the tool. Never let any liquid get inside the tool;

never immerse any part of the tool into a liquid.

IMPORTANT: To assure product SAFETY and

RELIABILITY, repairs, maintenance and adjustment

(other than those listed in this manual) should be

performed by authorized service centers or other

qualified service organizations, always using identical

replacement parts.

NOTE: Certain cleaning chemicals can damage

plastic parts.

6. Avoid use of cleaning chemicals or solvents,

ammonia and household detergents containing

ammonia.

LUBRICATION

All motor bearings are permanently lubricated at the

factory and require no additional lubrication.

On all mechanical parts of your table saw where a pivot

or threaded rod are present, lubricate using graphite or

silicone. These dry lubricants will not hold sawdust as

would oil or grease.

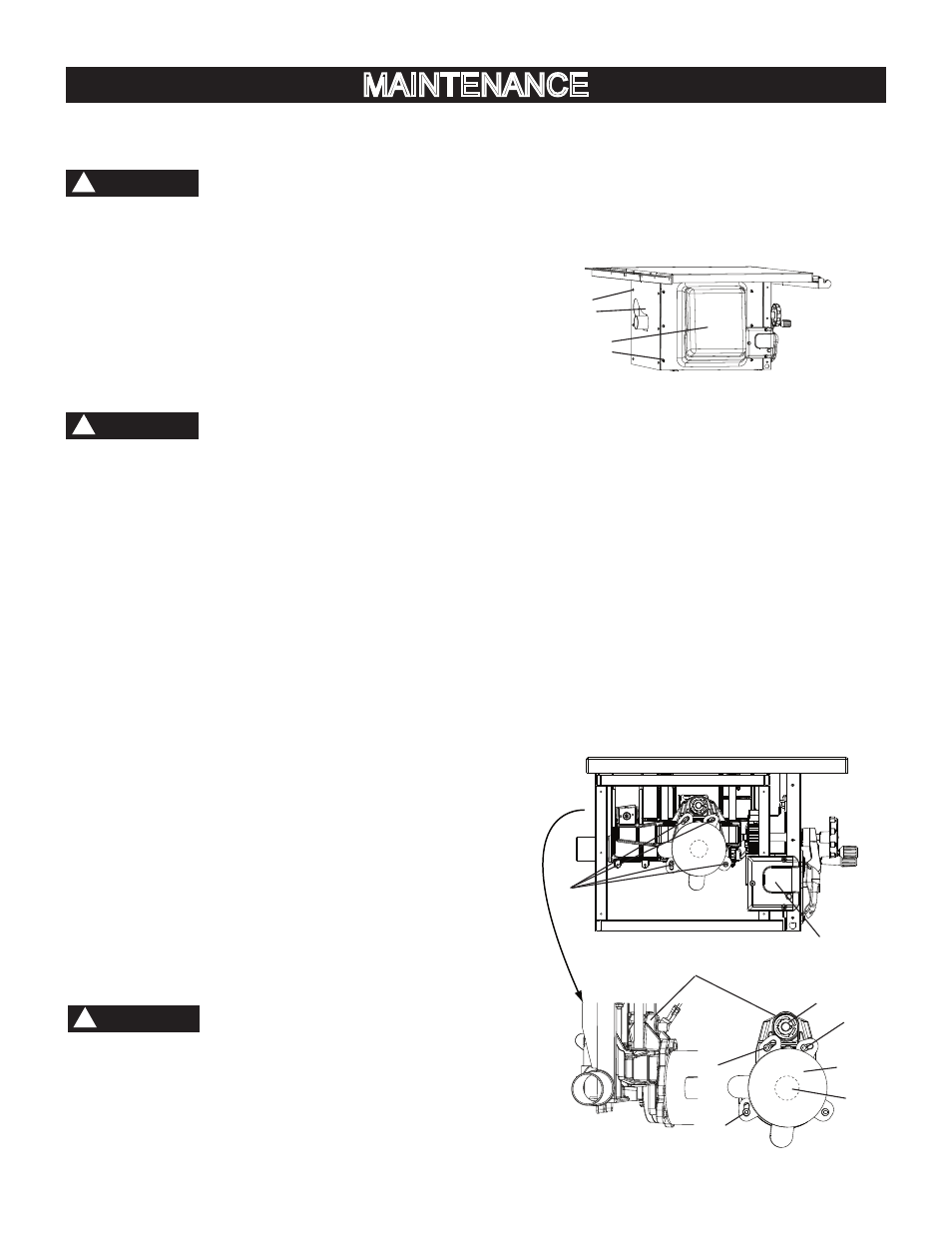

CHANGING DRIVE BELT (FIG. aa, bb)

All electrical or mechanical repairs should be

attempted only by a trained repair technician.

Contact the nearest Porter-Cable Authorized Service

Center for service. Use only identical replacement

parts. Any other parts may create a hazard.

NOTE: Occasionally changing the drive belt may be

necessary as a result of normal wear and use.

1. Unplug the unit from power source. Lower the blade

to its lowest position.Turn the blade tilting handwheel

until the blade tilting scale is around 45°.

2. Remove the rear body shell (1) and left body shell (2)

by removing the twelve screws (3), slide the left body

shell backwards.

Fig. aa

3. Turn the blade tilting handwheel until the blade tilting

scale is around 0°.

4. Loosen four bolts (4) two full turns using a 6 mm hex

key. Do not remove the bolts.

5. Rotate the motor (5) slightly to reduce the tension on

the driven pulley (6). The three curved slots (7) allow

for the movement of the motor.

6. Remove the old belt from the pulleys.

7. Fit the new belt on the motor pulley (8) first and then

on the driven pulley (6).

NOTE: Make sure the belt is

fitted properly on the central position of pulleys.

8. Lower and rotate the motor (5) downwards away

from the driven pulley (6) along the curved slots (7).

9. Tighten four bolts (4) securely.

10.Test the drive belt by hand and check to confirm that

drive belt runs smoothly and straight on the pulleys.

11.Replace the rear body shell (1) and left body shell (2)

with the screws (3).

Fig. bb

MAINTENANCE

WARNING

!

WARNING

!

3

1

2

3

4

7

7

5

8

Drive belt

Overload box

(remains on unit)

7

6

WARNING

!

Rear side view