Porter-Cable PCB270TS User Manual

Page 24

– 24 –

AVOID KICKBACK by pushing forward on the

section of the workpiece that passes between the

blade and the fence. Never perform any freehand

operations.

Fig. PP

NOTE: Always use a push stick. When width of the rip is

narrower than 2 in. (50.8 mm) the push stick cannot be

used because the guard will interfere. Therefore, use

the auxiliary fence so the push stick can be used as

shown on page 32.

7. Keep your thumbs off the table top. When both of

your thumbs touch the front edge of the table (2),

finish the cut with a push stick. To make an additional

push stick, use the pattern on page 32.

8. The push stick (3) should always be used.

9. Continue pushing the workpiece with the push stick

until it passes through the blade guard and clears the

rear of the table.

10.Never pull the piece back when the blade is turning.

Turn the switch OFF. When the blade completely

stops, you can then remove the workpiece.

BEVEL RIPPING

This cut is the same as ripping except the blade bevel

angle is set to an angle other than 0°.

SETTING BEVEL ANGLE (FIG. QQ)

1. To set the bevel angle, loosen the blade bevel

lock handle (1) which is the handle on the blade

elevation handwheel (2), and then turn the blade

tilting handwheel (3) counterclockwise to bevel the

blade to the left. Turn the blade tilting handwheel (3)

clockwise to return the blade to the vertical position.

2. To lock the blade at the required bevel setting, turn

the blade bevel lock handle (1) counterclockwise.

Always release the blade bevel lock handle prior to

changing the bevel setting and relock the handle

after the required bevel angle is set.

3. If the blade bevel lock handle (1) interferes with the

blade tilting handwheel (3) while it is being tightened

the handle can be pulled forward to allow it to be

CUTTING OPERATIONS

There are two basic types of cuts: ripping and

crosscutting. Ripping is cutting along the length and the

grain of the workpiece. Crosscutting is cutting either

across the width or across the grain of the workpiece.

Neither ripping nor crosscutting may be done safely

freehand. Ripping requires the use of the rip fence, and

crosscutting requires the miter gauge.

Before using the saw each and every time, check

the following:

1. The blade is tightened to the arbor.

2. The bevel angle lock knob is tight.

3. If ripping, the fence is locked into position and is

parallel to the miter gauge groove.

4. The blade guard is in place and working properly.

5. Safety glasses are being worn.

6. Make sure casters are released in the up position

and that all four legs are resting evenly on the floor.

The failure to adhere to these common safety rules, and

those printed in the front of this manual, can greatly

increase the likelihood of injury.

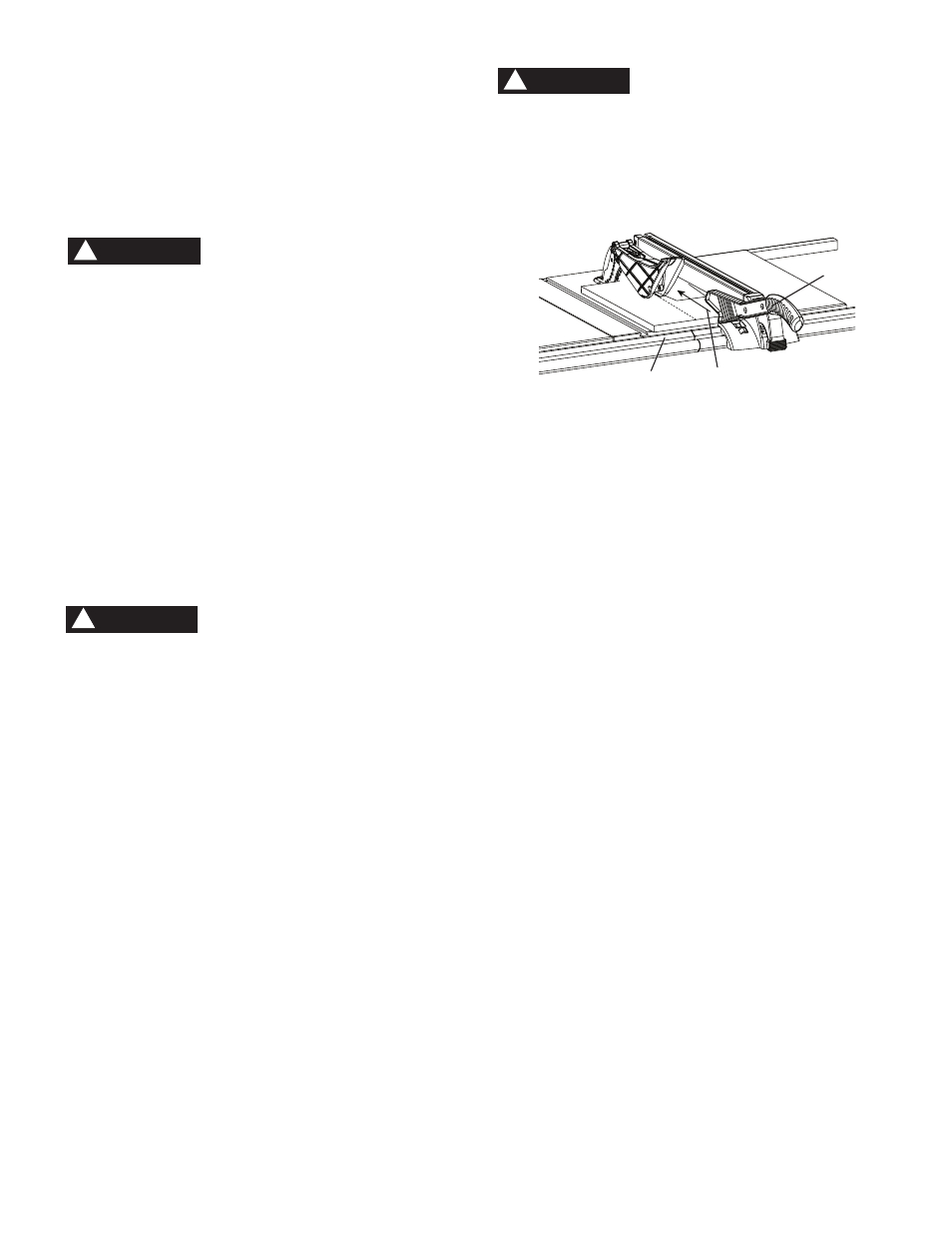

RIPPING (FIG. PP)

To prevent serious injury:

•

Never use a miter gauge when ripping.

•

Do not allow familiarity or frequent use of your

table saw to cause careless mistakes. Remember

that even a careless fraction of a second is

enough to cause a severe injury.

•

Keep both hands away from the blade and clear

from the path of the blade.

•

The workpiece must have a straight edge against

the fence and must not be warped, twisted, or

bowed when ripping.

1. Remove the miter gauge, and hang it on the miter

guage storage loacted on the right side of stand.

2. Secure the rip fence to the table.

3. Raise the blade so it is about 1/8 in. (3.2 mm) higher

than the top of the workpiece.

4. Place the workpiece flat on the table and against the

fence. Keep the workpiece away from the blade.

5. Turn the saw ON and wait for the blade to come to

full speed.

6. Slowly feed the workpiece into the blade by pushing

forward only on the workpiece section (1) that will

pass between the blade and the fence.

WARNING

!

WARNING

!

WARNING

!

1

2

3