Troubleshooting – Lochinvar Hot Water Generator User Manual

Page 14

14

5

Troubleshooting

Hot Water Generator Installation and Operation Manual

S

SY

YM

MP

PT

TO

OM

M

P

PR

RO

OB

BA

AB

BL

LE

E C

CA

AU

US

SE

E

C

CO

OR

RR

RE

EC

CT

TIIV

VE

E A

AC

CT

TIIO

ON

N

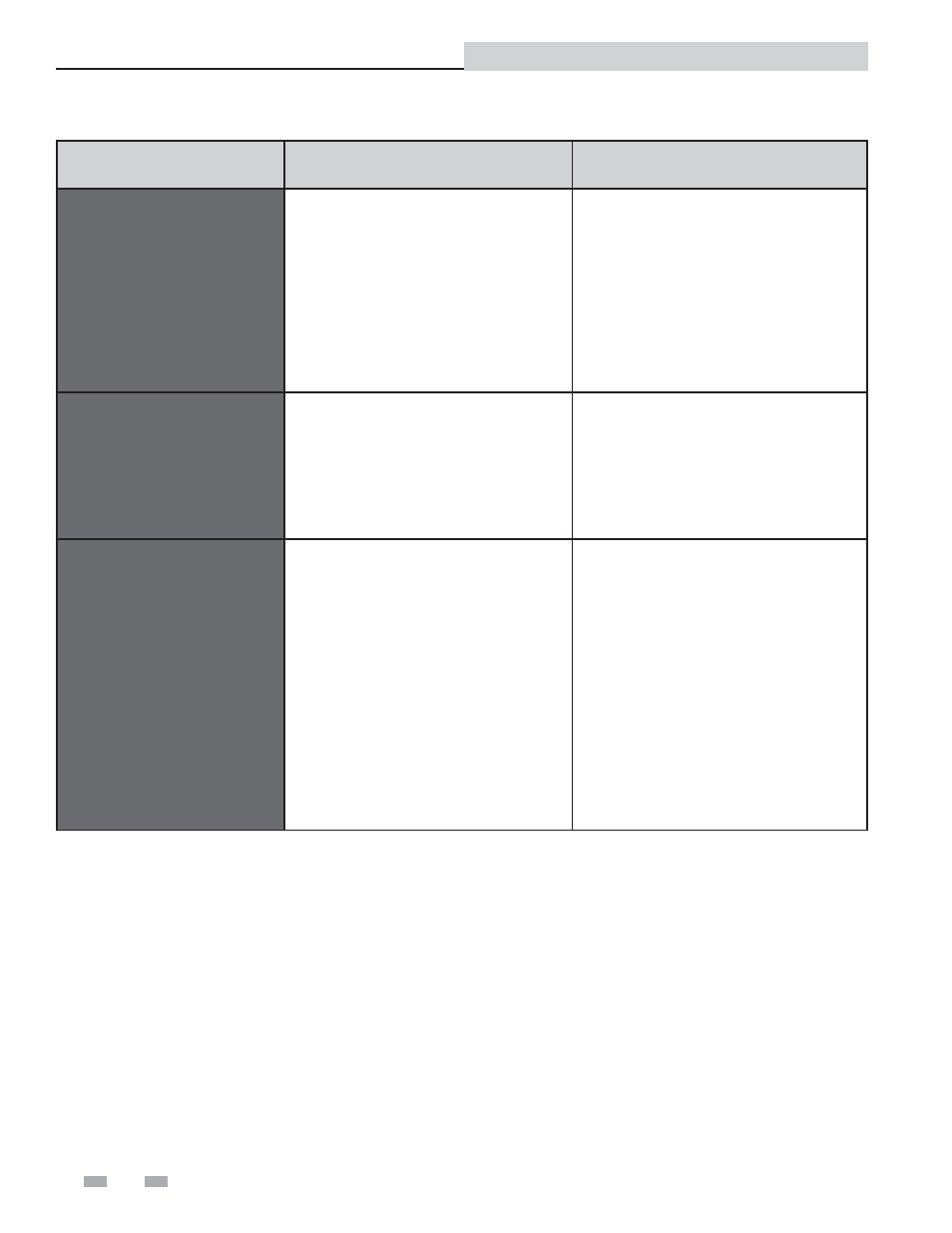

Pressure relief

valve

“pops”.

• The primary / inlet temperature control

valve is not closing properly.

• The secondary / outlet energy source

pressure control system is not

operating properly.

• The over-temperature limit system is

out of adjustment, or some component

of the system has failed.

• Verify control valve bulb was installed in

tank bulbwell.

• Verify control valve actuator is

operating properly.

• Check the individual components of the

system and repair or replace the failed

component(s) as necessary.

Water shuts down at or

too close to (above or

below) the design outlet

temperature.

• The over-temperature limit system is

out of adjustment, or some component

of the system has failed.

• Check the individual components of the

system and repair or replace the failed

component(s) as necessary.

A loud banging in the

water heater,

primary

piping, or condensate /

water return piping (not

to be confused with a

normal clicking noise

made during operation).

• The condensate / water return piping

has not been installed properly,

allowing the condensate / water to

drain freely (by gravity); the

condensate / water drain line is

restricted; or the condensate / water

check valve is leaking or has failed.

• Primary / inlet steam line is not

properly trapped (steam as energy

source only).

• Reconfigure the condensate / water

return piping and check valve to allow

for proper drainage. Check to assure

that there is no restriction in the

condensate / water drain line. Replace

the check valve if it is leaking or has

failed. Also, check to assure that there

is no restriction in the condensate /

water drain line.

• The steam supply should be clean dry

steam. Do not slug controls system

with boiler startup condensate. This

can damage controls as well as tube

bundle.