Troubleshooting – Lochinvar Hot Water Generator User Manual

Page 12

12

5

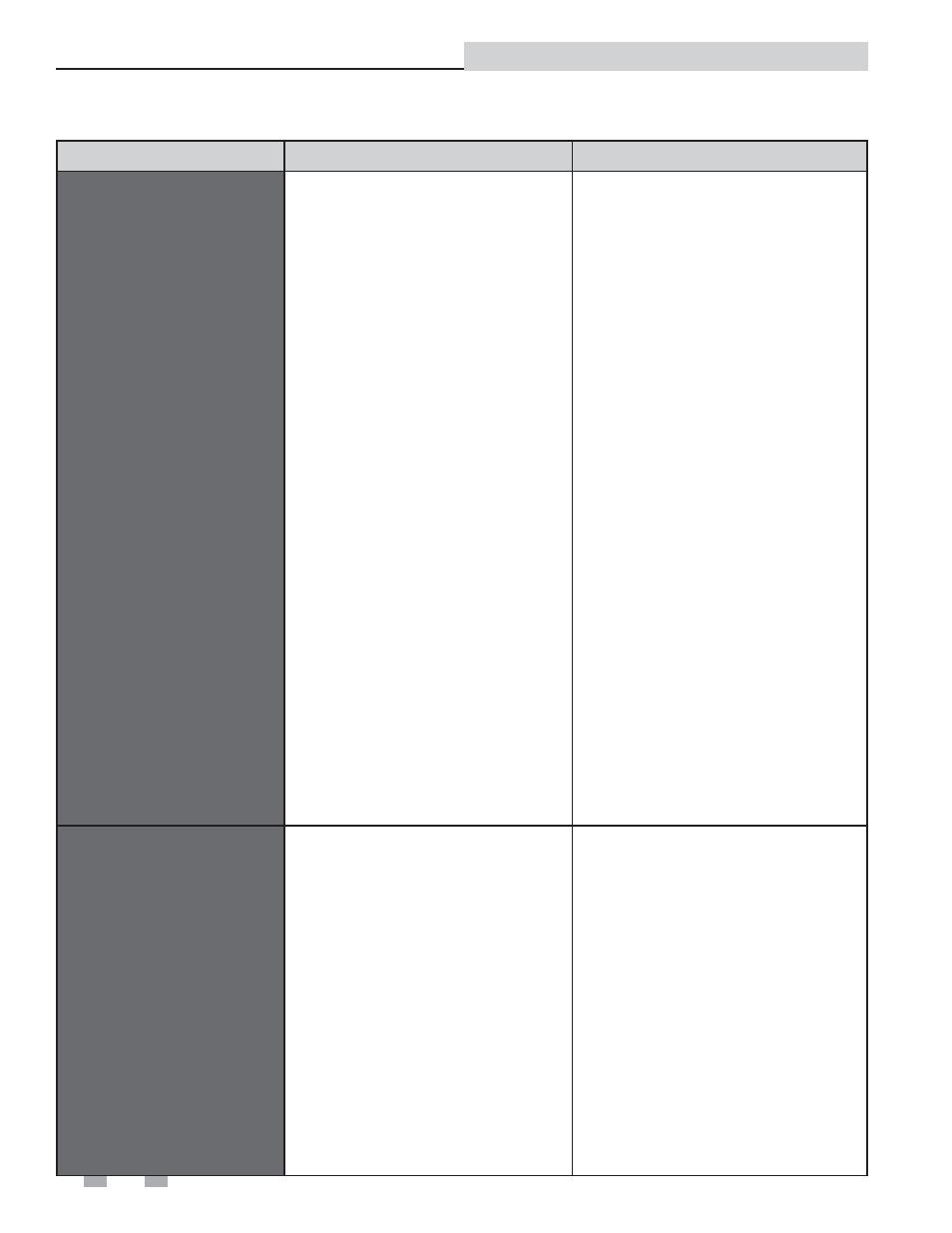

Troubleshooting

Hot Water Generator Installation and Operation Manual

S

SY

YM

MP

PT

TO

OM

M

P

PR

RO

OB

BA

AB

BL

LE

E C

CA

AU

US

SE

E

C

CO

OR

RR

RE

EC

CT

TIIV

VE

E A

AC

CT

TIIO

ON

N

Water heater does not

maintain the required

temperature at the rated

capacity.

• The thermometer is not correctly

sensing the water temperature.

• Inlet energy source pressure is too

low or boiler water temperature is too

low.

• The condensate / water return piping

has not been installed properly,

allowing the condensate / water to

drain freely (by gravity); the

condensate / water drain line is

restricted; or the condensate / water

check valve is leaking or has failed.

• Water bypass valve has not been

adjusted (boiler water).

• Control valve bulb not installed or not

properly installed in tank bulbwell.

• Control valve actuator defective.

• Check the water temperature with a

temperature gauge that is known to be

correct. Replace the thermometer if it

is found to be incorrectly sensing the

water temperature.

• Check the primary energy source

pressure/temperature. If the reading is

low, adjust the inlet pressure/temperature to

meet the design requirements. If there is a

restriction in the primary energy source

line, the pressure reading will drop

excessively when the generator calls

for full energy on steam systems, even

though the pressure seems to be

normal during light demand. If the

primary pressure is correct, the system

should reach design pressure for

energy source in the tube bundle as the

temperature of the water in the tank

heater approaches shutoff.

• Reconfigure the condensate / water

return piping and check valve to allow

for proper drainage. Check to assure

that there is no restriction in the

condensate / water drain line. Replace

the check valve if it is leaking or has

failed. Also, check to assure that there

is no restriction in the condensate /

water drain line.

• Adjust bypass valve approximately half

closed. Readjust as necessary.

• Notify factory for replacement.

• Verify actuator is not working. Notify factory

for replacement.

Outlet temperature is too

high.

• The thermometer is not correctly

sensing the water temperature.

• The condensate / water return piping

has not been installed properly,

allowing the condensate / water to

drain freely (by gravity); the

condensate / water drain line is

restricted; or the condensate / water

check valve is leaking or has failed.

• Control valve bulb not installed or not

properly installed in tank bulbwell.

• Control valve actuator defective.

• Check the water temperature with a

temperature gauge that is known to be

correct. Replace the thermometer if it

is found to be incorrectly sensing the

water temperature.

• Reconfigure the condensate / water

return piping and check valve to allow

for proper drainage. Check to assure

that there is no restriction in the

condensate / water drain line. Replace

the check valve if it is leaking or has

failed. Also, check to assure that there

is no restriction in the condensate /

water drain line.

• Verify bulb is installed in bulbwell.

• Verify actuator is not working. Notify factory

for replacement.