Ln-25 across the arc model, Electrical diagrams, Psoc – Lincoln Electric LN-25 SVM114-C User Manual

Page 96: G5366, G53 66

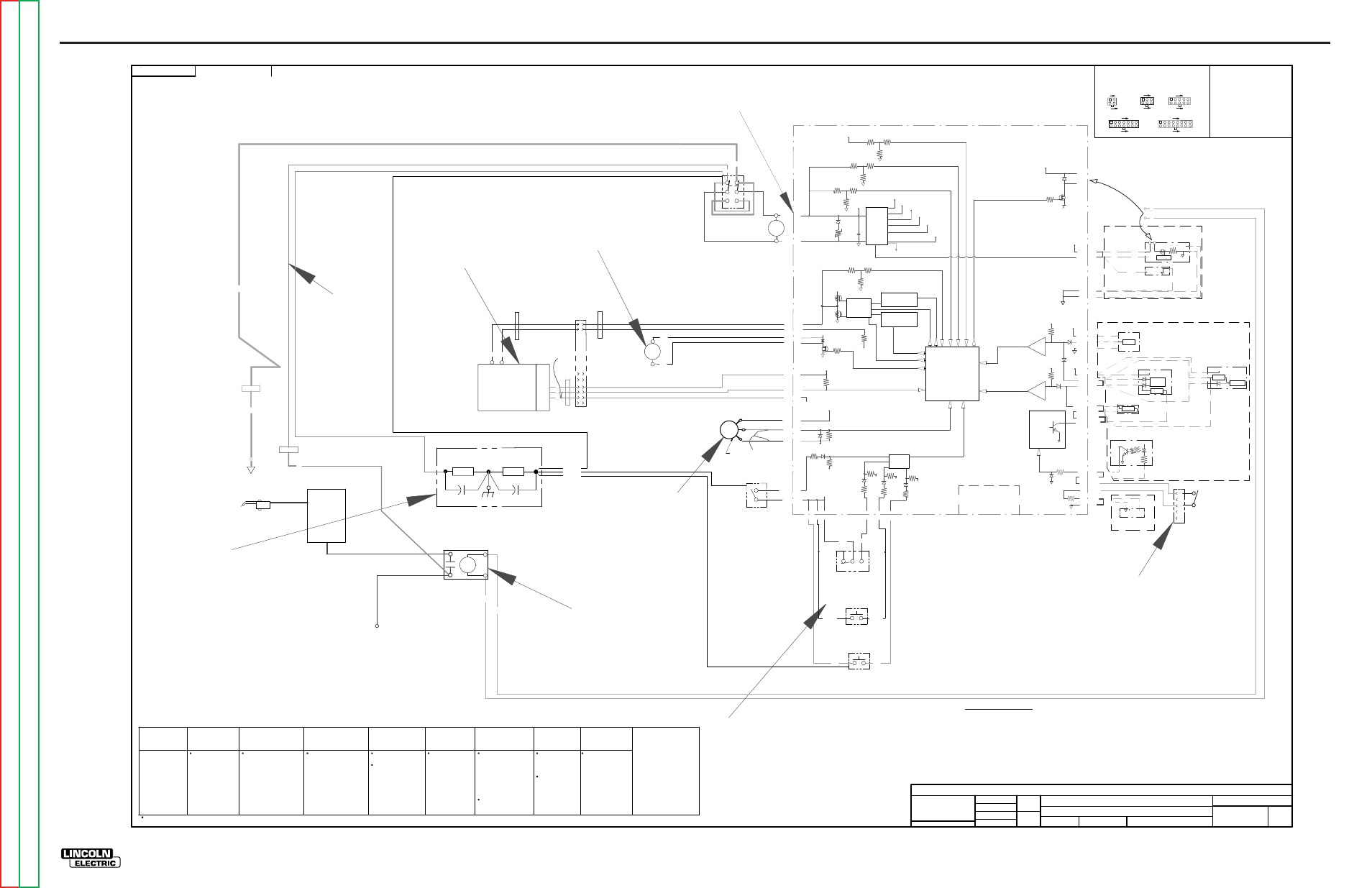

ELECTRICAL DIAGRAMS

G-6

¤

¤

SCHEMATIC - COMPLETE MACHINE - CODES ABOVE 11140 (G5366)

E

N

-1

7

0

G5366

LN-25 (ACROSS THE ARC)

MACHINE SCHEMATIC

NONE

G4198-1

M. DIDION

M. DIDION

DO NOT SCALE THIS DRAWING

DRAWN BY:

DESIGN INFORMATION

ENGINEER:

APPROVED:

REFERENCE:

EQUIPMENT TYPE:

SUBJECT:

SCALE:

MATERIAL

DISPOSITION:

APPROVAL

DATE:

PROJECT

NUMBER:

NA

CRM36946

1

PAGE ___ OF ___

1

ENGINEERING CONTROLLED

MANUFACTURER:

No

DOCUMENT

NUMBER:

DOCUMENT

REVISION:

THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION OWNED BY LINCOLN GLOBAL, INC. AND MAY NOT BE DUPLICATED, COMMUNICATED

TO OTHER PARTIES OR USED FOR ANY PURPOSE WITHOUT THE EXPRESS WRITTEN PERMISSION OF LINCOLN GLOBAL, INC.

PROPRIETARY & CONFIDENTIAL:

A

10/4/2004

NEW

CHANGE DETAIL:

t

MATERIAL TOLERANCE (" ") TO AGREE

WITH PUBLISHED STANDARDS.

ON ALL ANGLES IS ± .5 OF A DEGREE

ON 3 PLACE DECIMALS IS ± .002

ON 2 PLACE DECIMALS IS ± .02

UNLESS OTHERWISE SPECIFIED TOLERANCE:

MANUFACTURING TOLERANCE PER E2056

S

O

L

ID

E

D

G

E

G53

66

LN-25 ACROSS THE ARC MODEL

J14

CAVITY NUMBERING SEQUENCE

(COMPONENT SIDE OF P.C. BOARD)

J1

6

5

10

1

3

4

1

2

J3

9

8

16

1

4

6

1

3

GENERAL INFORMATION

ELECTRICAL SYMBOLS PER E1537

COLOR CODE

B -

BLACK

WHITE

R -

RED

U -

BLUE

J2

CONTACTOR

300A 60%

WORK

CLIP

A

D

C

B

E

J3

552

553

GAS

SOLENOID

690

541

539

691

TRIGGER

CONNECTOR

578

507

523

509

621

522

MODE

500

WIRE FEED SPEED

CONTROL

POTENTIOM ETER

21

MOT OR /

GEARBOX

TACH.

67

7

2

1

8

4

3

W

B

B

J2

INPUT ELECTRODE

CABLE CONNECTION

GUN

TRIGGER

INPUT

.0047/.005 mfd,

1400VDC

1M ohms

6

5

GND-S2

1

2

3

MO V ASBLY

1.9VDC

@ 50

i

n/mi

n

20.1VDC

@ 700

i

n/mi

n

8sec

average

Current

l

i

mi

t

=3.5Amps

(Li

mi

ti

ssoftwareset)

MeasureB toU

130

Hz

@ 50

i

n/mi

n

1.85

kHz

@ 700

i

n/mi

n

13.5VDC T

ach

Suppl

y

4.25

VDC

when

gas

fl

owi

ng

Coi

lmeasures

21

ohms

PW M

control

l

ed

G

a

s

P

u

rg

e

C

o

ld

In

c

h

Bussbar from

i

nput

stud

tocont

actor

R

U

COM

POT Suppl

y

W ip

er

W i

per toCOM

5VDC

at

700

i

pm

0VDC

at

50

i

pm

10K

Ohms

Coi

lmeasures

4.4ohms.

0VDC

Open

3.0VDC

Cl

osed

12

VDC

coi

l

PW M

Control

l

ed

Model

Ranger 8,9

Classic

Ranger 250, 305

Commander 300,400,500

(Common Analog

Controls)

V350

(Common Digital

Controls)

DC-400, 600

Square Wave TIG

300/355

Miller Inverters

STT II

K449

Across the Arc

Recommended

all CV operation.

Recommended for CV

operation. (Wire

Feed Module

Required)

Recommended for CV

operation.

Recommended for

CV operation.

Not recommended

for use when

pulse welding.

Recommended

for CV and CC

operation.

Not recommended

for CC operation

because the

customer may

experience short

contactor life from

inductive nature of

the power source.

Not recommended

with high frequency

TIG starting.

Recommended

for CV voltage

sense

operation.

Not

recommended

for use when

pulse welding.

Not recommended

for STT operation.

Note:

Most semiautomatic wire

welding processes

perform better using

constant voltage power

sources. Be sure the

proper power source is

used for your application.

Contactor life may be

shortened in applications

using CC machines with

high OCV.

Wire Drive

Circuit

Positive

Voltage

Feedback

Input

Voltage

Protection

Contactor

WFS

Control

Circuit

Gun Trigger

Circuit

Inch/Purge/Mode

Input Switches

Gas Solenoid

Circuit

Motor

-

Gas

Sol

enoi

d+

Gas

Sol

enoi

d-

Tach

COM

J2-1

LN-25 FEEDHEAD

P.C. BOARD

512

500

Vin

-

+

+Vin

632

555

631

633

TachSig

nal

MOTOR SUPPLY

VOLTAGE MONITOR

POWER

SUPPLY

+35V

+15V

+13.5V

+5V

+15V_ISO

ISO

.05uF

+35V

INPUT VOLTAGE

MONITOR

(MOTOR FETS ARE

BOTH OFF WHEN INPUT

VOLTAGE DROPS

BELOW 20V)

+VM

COM

+13.5V

TACHOMETER

COM

DRIVE

BRAKE

+ VM

PWM

MOTOR

CONTROL

PULSE BY PULSE

PEAK CURRENT

LIMIT

AVERAGE

CURRENT

LIMITING

+35V

SWITCH

INPUTS

COM

+13.5V

ARC

VOLTAGE

FEEDBACK

Schemati

cG4616

500

For programming at LECo

factory only.

Not field reprogrammable.

Motor+

FEEDPLATE

TOROID

TOROID

TOROID

TOROID

+35V

4.5 A PEAK

CURRENT

LIMIT

Located behind

the glastic panel

next to the motor.

PSOC

Located behind the wire drive

(European Models Only)

Not a

PC board; no schemati

c.

Access this connector

by removing the wire

drive asbly.

Located on the case front.

Remove the wire drive

asbly to gain access.

Located on the lower left

of the front of the case.

N.A.

CAVITY NUM BERING SEQUENCE AS VIEW ED FROM COM PONENT SIDE OF BOARD.

N.B.

CAVITY NUM BERING SEQUENCE AS VIEW ED FROM LEAD SIDE OF CONNECTOR.

N.C. T

OGGLE SWITCHES AND POTENTIOM ETERS SHOW N FROM CONNECTION SIDE OF SWITCH.

Located behind the insulating

wire drive panel. Remove the

wire drive ably to gain access.

Located under the cover

at the rear of the feeder

WFS RANGE

M

o

d

e

Tri

gger

13.5VDC

when

Open,

0VDC

when

Tri

gger Cl

osed

667

J1-1

PURGE

S1

67

21

21

VOLTM ETER

+Vin

J1-3

J3-10

J3-14

621

624

J3-6

J4-14

J4-13

.05

J2-3

J2-6

J4-5

10K

J4-12

J4-7

COM

+5V

J4-9

100K

J4-1

J4-8

COM

COM

COM

530(B)

500(B)

608

621

COLD

INCH

J2-4

J14-7

J14-6

J4-3

J4-11

J4-10

J4-4

509

530

608

523

523B

J2-2

J2-5

J4-6

DATA SCLK XRES

J3-7

COM

500A

J3-8

3.3K

622A

J1-4

500A

J1-2

J3-5

J3-16

622A

622

COM

JC*

JR

COM

OLD

REMOTE BD

(optional)

-DC

JR

OLD

REMOTE BD

(optional)

+V

667

JS

JR

REMOTE BD

(optional)

OLD

CONTACTOR BD

(optional)

+V

JC

+V

621

J3-15

500

J4

7

8

14

1

to Timer Bd

ACTIVATE

FEEDER

530A

J3-3

530A

J3-12

J14-5

J3-11

530A

530

JS

JT

ACTIVATE

SOLENOID

COM P

REF

+13.5V

J14-10

530

JS

JR

JC

JS

606

J3-1

JR

JR

JC

COM P

REF

+13.5V

J14-8

606

JT

OLD

REMOTE BD

(optional)

TIMER BD

(optional)

(606)

(530)

C LOGIC

C LOGIC

C LOGIC

TIMER

TIMER

TIMER

TIMER BD

(optional)

TIMER

J14-4

J14-2

512

500

+13.5V

J3-13

+13.5V

512

(512)

+V

OLD CONTACTOR BD

(optional)

+V

CC

SENSE

J14-1

U

J14-9

U

J3-2

J3-4

/SS MOSI

TRIGGER

LOGIC

WFS POT

SOL_DRV

B

RA

K

E

_

DRV

IM

_

A

V

G

PWM_DRV

VIM_PEAK

M

O

T

O

R_

V

S

E

NS

E

CC_

S

E

NS

E

A

RC_

V

S

E

NS

E

+

3

5

V

_

S

E

NS

E

CO

NT

_

DRV

COM

COM

COM

COM

The WFS switch shown in low range.

The low WFS range is 50-350 in/min.

The high WFS range is 50-700 in/min.

The mode switch is

shown in CC mode.

Located on rear

of case.

Located inside case

below voltmeter.

Located inside case.

Located on front of case,

above WFS control knob.

(500A)

(500)

(622A)

(622)

(512)

(606)

(500)

(606)

(530)

(512)

(530)

(530A)

(530A)

(530A)

(667)

(624)

(624)

(621)

(621)

(500)

OPTION BOARD EXPLANATION

Therearethree

opti

onal

boards

avai

l

abl

efor

the

LN-25. The

wi

ri

ng

associ

ated

wi

ththese

boards

i

si

ndi

cated

by

dashed

l

i

nes.and

the

abbrevi

ati

ons

areas

fol

l

ows:

JS

-StandardW i

ri

ng,

No

Opti

on

Boards

Instal

l

ed. Thi

swi

ri

ng

j

umper

must

be

i

nstal

l

ed

i

fremoteki

ti

snot

present.

JC

-Opti

onal

Contactor

Board.

JR

-Opti

onal

Remot

eBoard.

JT

-Opti

onal

Ti

mer

Board. Ifti

mer ki

ti

snot

i

nstal

l

ed,

and

remoteboardi

snot

present,then

j

umper

i

si

nstal

l

ed

i

nJ11.

Ifremoteboardi

spresent,then

j

umper

i

si

nstal

l

ed

i

nJ6

of

remoteboard.

The

Opti

onal

Boards

aredi

vi

ded

on

thi

spri

nt

for cl

ari

ty.

COM

COM

COM

COM

COM

COM

COM

N.O.

CC

CV

N.C.

Input Power

15V-110VDC

COM

621

J3-6

512

J3-13

+13.5V

JS

JC*

JS

CODES

11144,

11145,

11146

TOROID

250A 100%

N.O.

NOTE:

OLDER OPTION BOARDS MAY BE LEFT

IN CIRCUIT OR REMOVED. IF REMOVED,

A PROPER JUMPER PLUG NEEDS TO BE

INSTALLED.

1M ohms

.0047/.005 mfd,

1400VDC

GND-S5

GND-S1

G-6

NOTE: This diagram is for reference only. It may not be accurate for all machines covered by this manual.