Weld cable connection, Electrode cable connections, Work cable connection – Lincoln Electric LN-25 SVM114-C User Manual

Page 11: Wire feed drive roll and guide tube kits, Installation, Warning, Electrode cable connection

INSTALLATION

A-5

LN-25™

A-5

Install the barbed fitting and union nut to the

5

⁄

8

-18

female inert gas fitting on the front panel of the LN-

25™ case. Connect the

3

⁄

16

" I.D. gas hose from the gun

cable to the barbed fitting.

When the gun is to be removed, this fitting can be

easily detached by loosening the union nut.

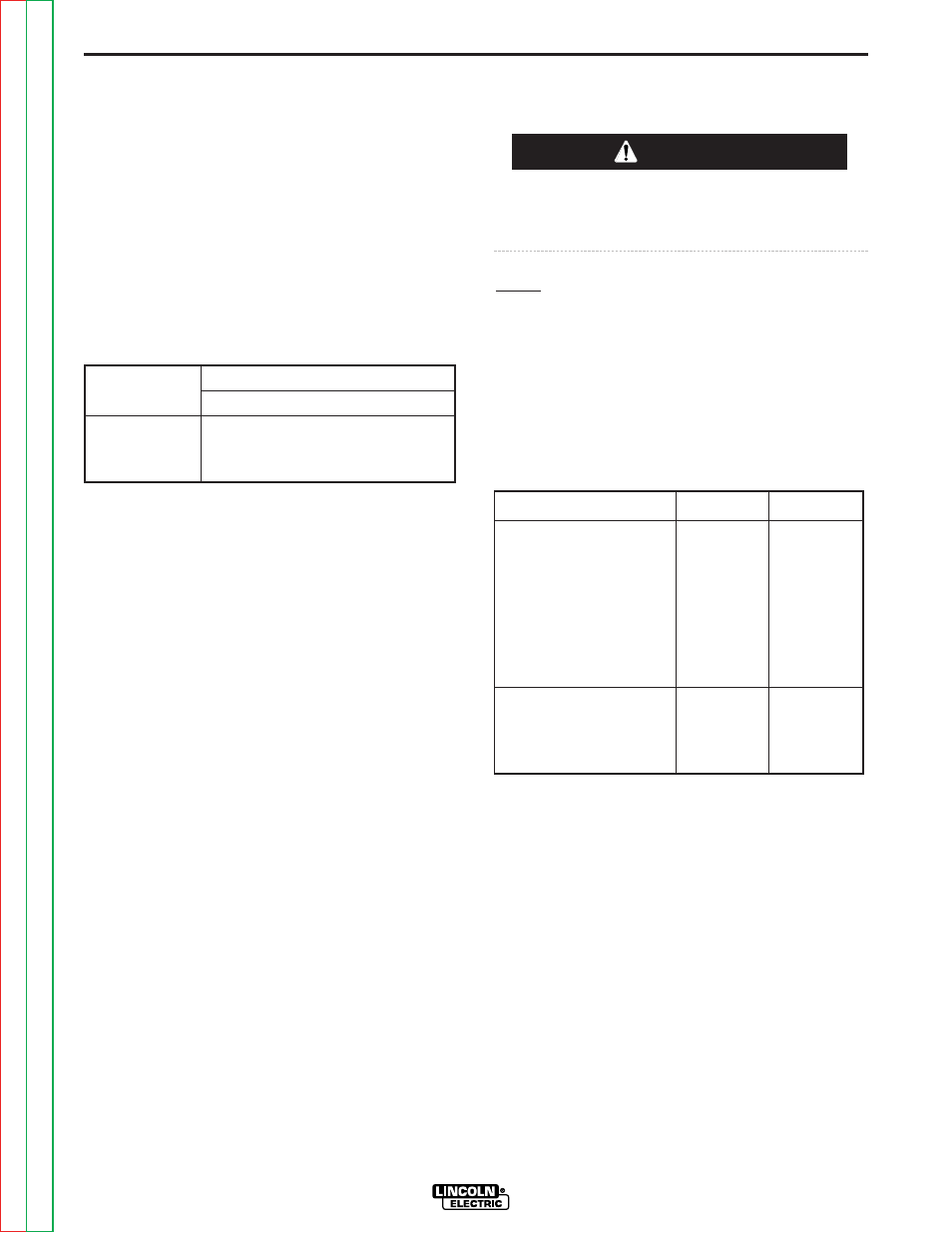

WELD CABLE CONNECTION

The size of the electrode cable and work cable must

be sufficient for the maximum weld current and total

cable length to be used. Refer to table A.1.

TABLE A.1

Total Cable Length

Weld Current

60% Duty Cycle

50'-100'

100'-150'

150'-200'

200'-250'

200Amps

2 AWG

2 AWG

1 AWG

1/0

300Amps

1 AWG

1 AWG

1/0

2/0

400Amps

2/0

2/0

3/0

3/0

500Amps

2/0

3/0

3/0

4/0

ELECTRODE CABLE CONNECTION

On units without an inter nal contactor route the

electrode cable through the oval hole in the LN-25™

rear panel, then along the case floor behind the reel

support and around the door side of the wire drive.

Connect the electrode cable to the LN-25™ using the

1

⁄

2

" bolt on the front of the wire drive.

On units with an inter nal contactor connect the

electrode cable to the LN-25™ electrode input cable

with the nut and bolt provided. Tape the bolted

connection.

ELECTRODE CABLE CONNECTION

(FOR LATER CODE NUMBERS ABOVE 10500)

Route the electrode cable through the oval hole

in the lower por tion of the LN-25™ rear panel.

Connect the electrode cable to the LN-25™ input

stud using the the 1/2” nut provided.

S e c u r e t h e c a b l e w i t h t h e s t r a i n r e l i e f c l a m p

provided. All units are supplied with an optional

pigtail for customers that prefer to make a taped

and bolted connection externally.

WORK CABLE CONNECTION

Connect a work lead of sufficient size between the

proper output stud on the power source and the

wor k. Be sure the connection to the wor k m a ke s

t i g h t m e t a l - t o - m e t a l e l e c t r i c a l c o n t a c t . Po o r

wor k lead connections can result in poor welding

performance.

WIRE FEED DRIVE ROLL AND

GUIDE TUBE KITS

Turn off power source before installing or changing

drive roll and/or guide tubes.

NOTE: The maximum wire sizes the LN-25™ will

satisfactorily feed are

5

⁄

64

" cored and

1

⁄

16

" solid electrodes.

The electrode sizes that can be fed with each roll and

guide tube are stencilled

(1)

on each part. Check the kit

for proper components. See the instructions, included

with the drive roll kit, to install these parts on new

machines or replace them on used machines. Refer

to table A.2.

TABLE A.2

Kit

Instructions

Steel Wire Sizes:

.068-

5

⁄

64

Cored

KP653-

3

⁄

32

L9932

1

⁄

16

(.062) Cored or Solid

-

1

⁄

16

Steel

(Can also be used for .052)

.045 and .052 Solid Steel

-.052

.045 and .052 Cored

-.052C

.035 Solid Steel

-.035S

.035 Cored

-.035C

.030 Solid Steel

-.030S

.025 Solid Steel

-.025S

Aluminum Wire Sizes:

1

⁄

16

KP654-

1

⁄

16

A

L9932

3

⁄

64

-

3

⁄

64

A

.035

-.035A

(1)

Drive rolls for only cored electrode sizes are stencilled with a

“C” suffix to the wire sizes.

Drive rolls for only solid electrode sizes are stencilled with an “S”

suffix to the wire sizes.

Drive rolls for aluminum wire sizes are stencilled with an “A” suffix

to the wire sizes.

WARNING