Making a weld, Figure b.4, Operation – Lincoln Electric LN-25 SVM114-C User Manual

Page 20

OPERATION

B-8

B-8

LN-25™

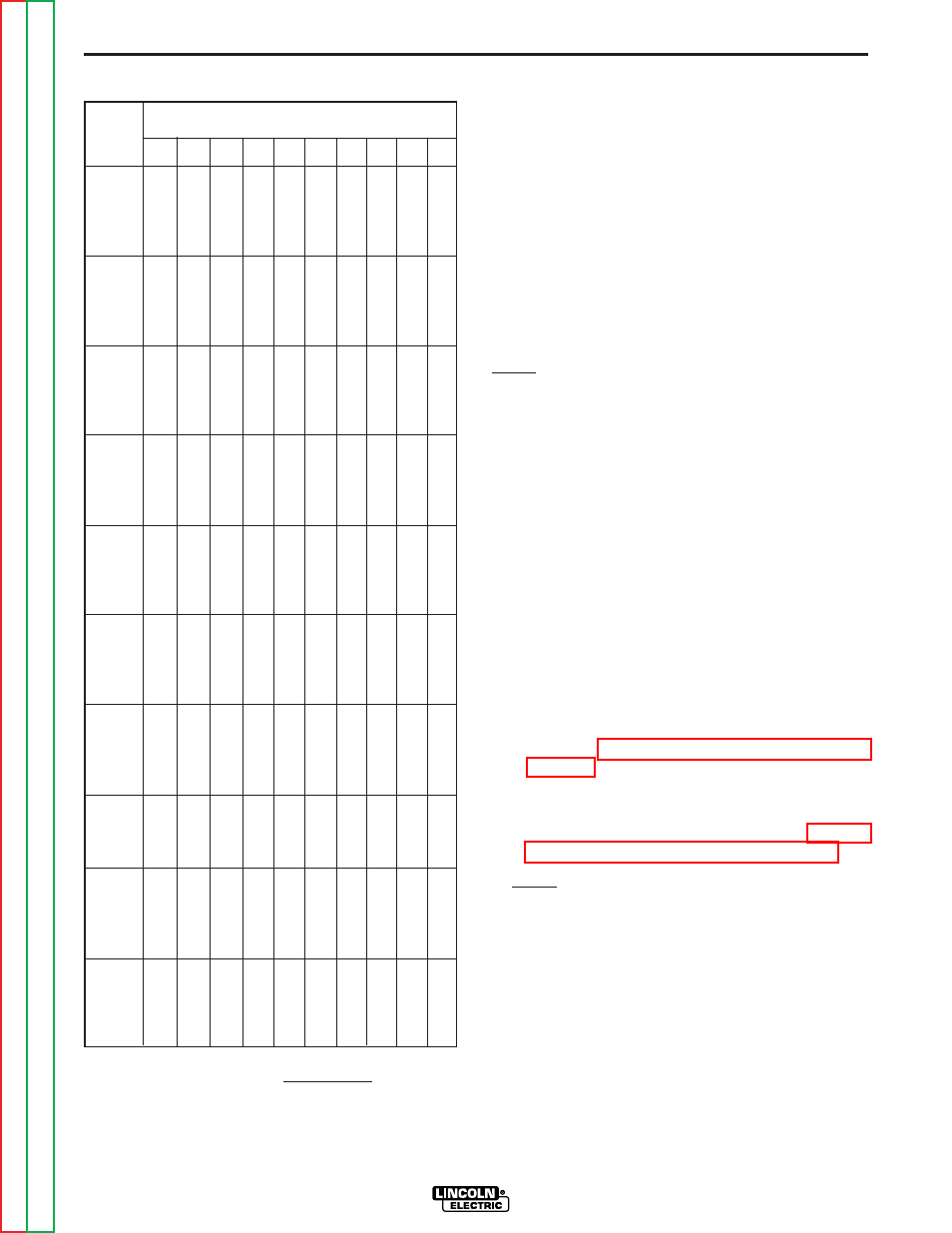

Arc Volts Used

Desired

In/Min

16

18

20

22

24

26

28

30

32

34

50

109

97

88

80

73

67

63

58

55

51

60

131

117

105

95

88

81

75

70

66

62

70

153

136

123

111

102

94

88

82

77

72

80

175

156

140

127

117

108

100

93

88

82

90

197

175

158

143

131

121

113 105

98

93

100

219

194

175

159

146

135

125 117

109 103

110

241

214

193

175

160

148

138 128

120 113

120

263

233

210

191

175

162

150 140

131 124

130

284

253

228

207

190

175

163 152

142 134

140

306

272

245

223

204

188

175 163

153 144

150

328

292

263

239

219

202

188 175

164 154

160

350

311

280

255

233

215

200 187

175 165

170

372

331

298

270

248

229

213 198

186 175

180

394

350

315

286

263

242

225 210

197 185

190

416

369

333

302

277

256

238 222

208 196

200

438

389

350

318

292

269

250 233

219 206

210

459

408

368

334

306

283

263 245

230 216

220

481

428

385

350

321

296

275 257

241 226

230

503

447

403

366

335

310

288 268

252 237

240

525

467

420

382

350

323

300 280

263 247

250

547

486

438

398

365

337

313 292

273 257

260

569

506

455

414

379

350

325 303

284 268

270

591

525

473

430

394

365

338 315

295 278

280

613

544

490

445

408

377

350 327

306 288

290

634

564

508

461

423

390

363 338

317 299

300

656

583

525

477

438

404

375 350

328 309

310

678

603

543

493

452

417

388 362

339 319

320

700

622

560

509

467

431

400 373

350 329

330

642

578

525

481

444

413 385

361 340

340

661

595

541

496

458

425 397

372 350

350

681

613

557

510

471

438 408

383 360

360

700

630

572

526

484

450 420

394 370

380

666

604

554

512

472 444

416 392

400

700

636

584

538

500 466

438 412

420

668

612

566

526 490

460 432

440

700

642

592

550 514

482 452

460

670

620

576 536

504 472

480

700

646

600 560

526 494

500

674

626 584

546 514

520

700

650 606

568 536

540

676 630

590 556

560

700 654

612 576

580

676

634 598

600

700

656 618

620

678 638

640

700 658

660

680

680

700

700

MAKING A WELD

SETUP

a. Connect work cable to metal to be welded. Work

cable must make good electrical contact to the

work. The work must also be grounded as stated

in “Arc Welding Safety Precautions.”

b. Check that the LN-25™ is properly connected to

the power source for the polarity and process to

be used, and appropriate power source settings

are made for the procedure to be used. (Refer to

p owe r s o u r c e o p e ra t i n g a n d c o n n e c t i o n

instructions.)

NOTE: If the K431-1 Remote Output Control Kit or

K624-1 42V Remote Control Module is installed but

the LN-25™ is to be used without the Remote Control

Cable Assembly, then the Remote Board harness plug

must be removed from the 16-pin receptacle on the

Control Board and the jumper plug (T13498-21)

reinstalled.

c. Place the LN-25™ conveniently near the work

area in a location to minimize exposure to weld

spatter and to avoid sharp bends in the gun cable.

d. Connect the LN-25™ Clip Lead to work and set

Po larity Switch to same polarity as electrode.

e. Set WIRE FEED MODE switch to CV or VV (CC),

as appropriate for the power source, then set the

proper DIAL RANGE and WIRE SPEED dial set -

ting for the proper wire feed speed per the welding

procedure:

For CV: Set dial to the calibrated IN/MIN desired.

(Refer to Setting Constant Wire Feed Speed

Section.)

For CC: Set dial to value determined from the CC

Wire Speed Graph for the DESIRED IN/ MIN

and ARC VOLTS to be used. (Refer to Setting

Arc Sensing Wire Feed Speed Section.)

NOTE: If procedure permits a range of acceptable

arc voltage, use the middle of the range to

determine proper WIRE SPEED setting.

f. If using the optional Gas Flow Timer, set the de -

sired PREFLOW TIME and POSTFLOW TIME.

g. Be sure the proper contact tip for the wire size

being used is in the gun, and the gun is safe

from work contact. (Use the LN-25™ insulated

gun holder.)

VV(CC) Speed Setting =

Desired IPM

X 35

Arc Volts

FIGURE B.4 – VV (CC) WIRE SPEED SETTING.