Lennox Hearth MERIT PLUS MP-36OD User Manual

Page 13

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

13

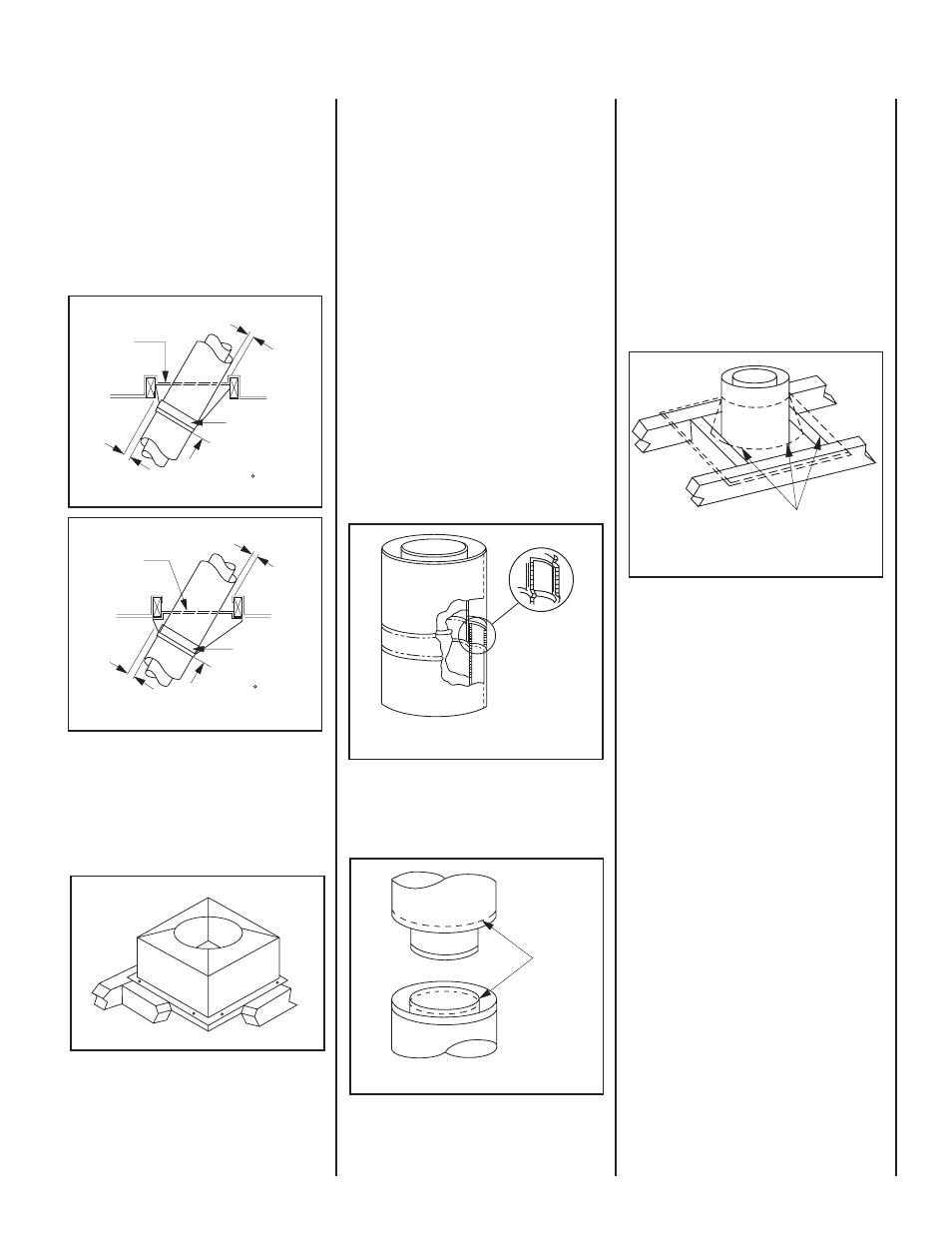

CHIMNEY 30° OFFSET THROUGH

FLOOR OR CEILING

It may be necessary to assemble the chimney

at 30° when passing through the fl oor or ceiling

area. Use the F8FS30 fi restop spacer as shown

in Figures 31 & 32. Support the chimney at fl oor

or ceiling penetration with a FTF8 stabilizer if

distance of chimney below ceiling is 10' or more.

Maintain 1"* minimum air space to combustibles

from chimney sections.

Figure 31

Step 4. Note: Chimney sections are constructed

with a unique locking tab design, which ensures

an immediate, tight assembly between sections.

Plan your chimney requirements carefully before

assembly as chimney is diffi cult to disassemble

after installation. If disassembled, the tabs

might become damaged. Be certain tabs are

properly formed to ensure locking tabs engage

properly.

The Security Chimney's FTF8 chimney system

is a two piece chimney, which snap together

from the fi replace up. Start with the inner fl ue

section with the lanced end up, snap lock it in

to the matching collar on top of the fi replace.

At all subsequent joints, the upper fl ue section

fi ts into the preceding fl ue section. Each piece

snaps together by means of locking tabs (9

locking tabs per joint). Check each piece by

pulling up slightly from the top to ensure proper

engagement before installing the next section.

If the fl ue has been installed correctly, it will not

separate when you test it. Also, the inner fl ue

joint where each section is joined should be

tight and fl at without gaps (Figure 34).

The outer chimney section installs the opposite-

way; the lanced end goes down and each new

section goes OVER the outside of the previous

section installed (Figure 35).

For Canada Only

When installing the chimney system through

an open attic space, the attic shield assembly-

fi restop spacer must be used (Figure 33). This

installation is required only for use in Canada.

Note: For Canadian installations, all chimney

installed outside the building must be con-

structed with galvalume on the outer sections

only (Note: galvalume is galvanized). The ap-

propriate model designations are located in the

F8FS30

Firestop Spacer

FTF8-S4 Stabilizer

1"

*

Min.

Air Space

30 Firestop

And Attic Above

10'

Max.

Attic Space

1"

*

Min.

Air Space

F8FS30

Firestop Spacer

FTF8-S4 Stabilizer

30 Firestop

And Room Above

10'

Max.

Room Above

1"

*

Min.

Air Space

1"

*

Min.

Air Space

Open Attic Space

Locking

Tabs

(Lances)

Figure 32

Figure 34

Figure 35

Figure 33

Note: Assemble one component of chimney at

a time (inner section fi rst, then outer section

last) before proceeding with the next complete

section.

Continue to assemble the chimney up through

framed opening. Assemble just enough to

penetrate the roof fl ashing openings (Figure

36). Always maintain 1"* minimum air space to

insulation and construction materials. Always

check each chimney joint (inner and outer)

to ensure proper engagement. Check vertical

alignment of chimney so that it projects from

the roof in true vertical position.

1"

*

Min. Air Space

To Combustibles

Figure 36

Security's chimney sections do not need to be

screwed together. Additional reinforcement is

not necessary except in certain offset conditions

(refer to Page 16, Figure 47).

Step 5. The height of vertical chimney pipe

supported only by the fi replace must not exceed

30'. Chimney heights above 30' must be sup-

ported by a Model FTF8-S4 stabilizer installed

at 30' intervals.

Note: The Model FTF8-S4 adds 3" net effective

height to the total chimney system.

Install the Model FTF8-S4 stabilizer by fi tting

inner section down into respective section of

proceeding fl ue pipe and locking outer stabilizer

section into place over the outer chimney pipe.

Position for proper clearance through framed

opening and nail straps securely (under tension

in “shear”) into place on framing. Use 8d nails.

Attach successive lengths of chimney pipe

directly to stabilizer using same techniques as

described in Step 4 (see Figure 37).

*Notes:

• 2" clearance to combustibles required in

Canada.