Locke TR-30 User Manual

Page 33

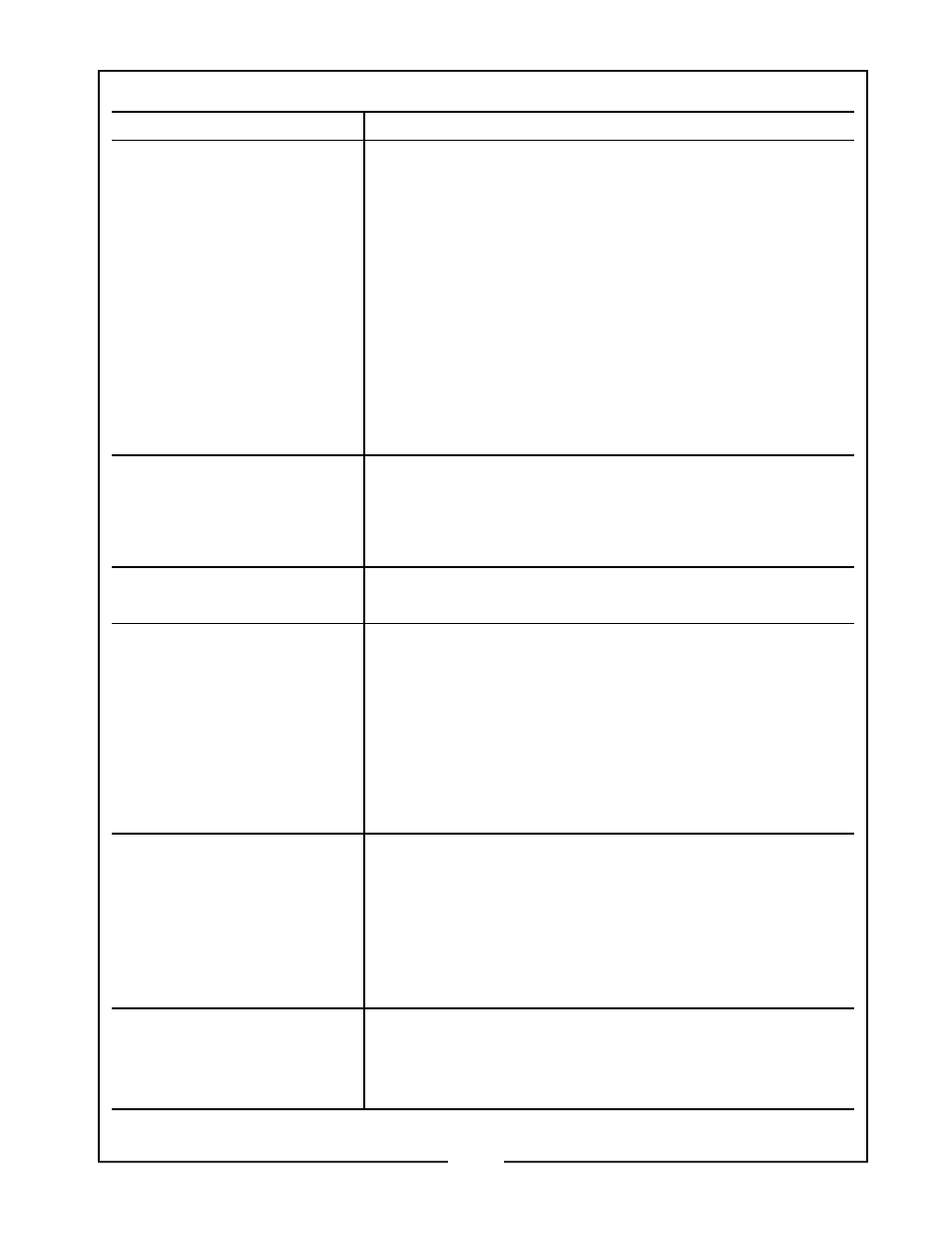

Solutions

a. Angle nozzles 20 degrees rearward.

b. Nozzle cap is obstructed or scratched. Clean nozzle gently with

water or solvent, using a toothbrush to clean the orifice hole in the

cap. Use a pipe cleaner to clean the metering feed hole in the

body. Steel picks, nails, etc. will damage the nozzle.

c. Disable the nozzle and clean inside surfaces, threads and any

sealing surfaces where the cap meets the body. Carefully inspect

the cap and body for any nicks, wear or chemical buildup. Tighten

nozzle cap firmly with torque wrench to 30 ft.lbs.

d. If nozzle output is high, the metering feed hole or internal cavity is

worn. Replace the nozzle.

e. Check nozzle spacing for correct overlap. Use 20” spacing on turf

booms.

f. Make sure that windy conditions are not affecting the spray pattern.

g. Check boom height.

a. Debris catching in throttling valves. Open gray throttling vale with

nozzles turned off and allow flow to flush out valves for about 15 sec-

onds per valve. Reset throttling valves.

b. If problem continues, replace filter screen with 50 mesh screen.

a. Check for proper lid fit.

a. Make sure agitation valve is open.

b. Check for obstructions or kinks on the agitation line.

c. Inspect agitator head for plugged holes.

d. Increase flow and pressure to agitation by increasing pump seed.

Do not exceed 4000 RPM or 90 psi.

e. Make sure chemicals were mixed properly. Do not allow chemi-

cals to settle in tank.

f. Agitate longer before spraying.

a. Check housing for cracks.

b. Housing gasket may be dried out and leaking. Allow gasket time

to absorb moisture and retighten bolts around housing in an even

manner.

c. Seal leaking, causing drip between pump and bearing housing. If

pump has been run dry, seal may be cracked. Replace seal.

d. Pinion shaft may be damaged at sealing surfaces. Replace.

a. Loosen end caps, then retighten equally to keep internal parts

from shifting.

b. If still leaking, disassemble valve and check that o-rings are in

good condition. Replace if necessary.

Problem

17. Nozzle shows streaking or a

collapsed pattern; nozzle

drips while spraying.

18. Throttling valves must be

readjusted after each tank

sprayed.

19. Liquid leaks out around tank

lid while spraying.

20. Chemicals will not stay in

suspension.

21. Pump leaks.

22. Ball valve leaks.

32