Locke TR-30 User Manual

Page 31

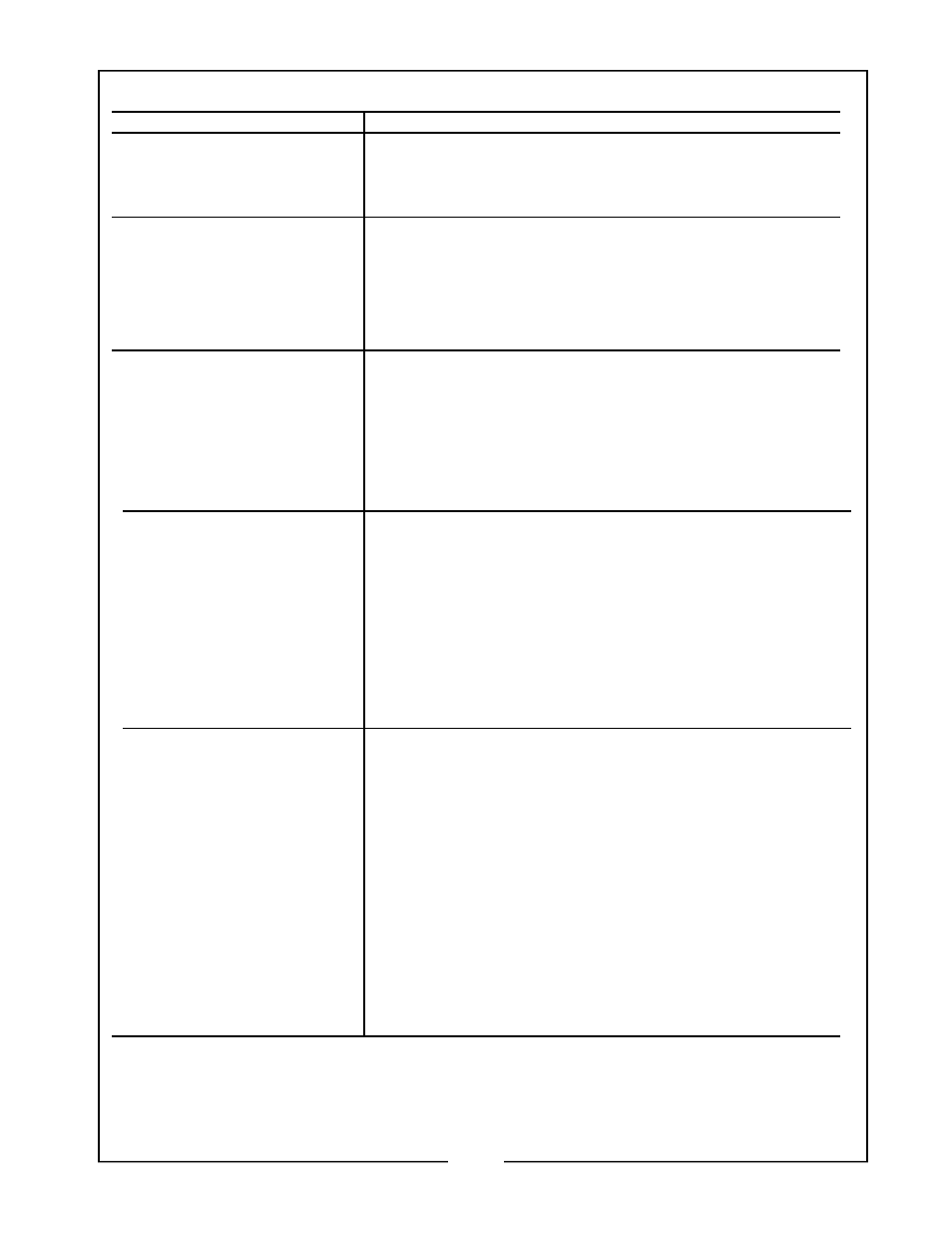

Solution

a. Throttling valves are becoming plugged. Open gray throttling

valve with nozzles turned off and allow flow to flush out valves

for about 15 seconds per valve. Reset throttling valves.

a. Throttling valves are becoming plugged. Unscrew gray knob on

throttling valve with boom sections turned off and allow to flow to

flush out valves for at least 15 seconds per valve. Reset the

throttling valves when finished.

b. Look for a restriction in the bypass line between the throttling

valves and the tank. If nozzle pressure returns to normal when

one or more boom sections are turned on, spraying accuracy is

unaffected.

a. Check GPM flow to be sure that pump has the capacity to spray

the desired volume.

b. Change to smaller size nozzles.

c. Reduce flow to agitation by partially closing agitation valve Make

sure that there is still adequate agitation after adjusting.

d. Check to be sure that manual pressure control vavle is open.

e. Increase engine RPM to increase pump output.

a. Low Flow: Check the boom feed line for that boom section for

blockage or kinks. Inspect check valves, nozzles, metered

manifold and electric solenoid valves for obstructions and chemi-

cal buildup. Remember, low voltage or a weak battery will result

in valves not opening completely. Check hose length leading to

manifold. If hose length is considerably longer than other sec-

tions, cut hose length to match length of other boom sections.

b. High flow: Check the boom feed line for that boom section for

length. If feed line is much shorter than other boom sections,

replace with longer line. Check to see that all nozzles are the

same size.

a. Recheck calibration.

b. Ground speed is slower than calibrated speed. Recheck speed

using method in application guide.

c. Check to make sure all nozzles are correct and the same size.

One oversized nozzle will result in over-application.

d. Check nozzle spacing.

e. Check control box gauge.

f. Overlap of rows may be too great causing double application in

some area.

g. Check levels in tank. Less than calculated amount would falsely

indicate over application.

h. Check for worn nozzles. Nozzles should be within 10% of

specs. Replace if necessary.

i. Check for possible wheel slippage.

Problem

8. Suspect faulty control box

gauge because pressure

changes when turning off

boom sections.

9. After correctly setting the

throttling valves, boom pres-

sure will not stay constant

when a section of the boom is

turned off.

10. Cannot increase boom pres-

sure to desired setting al-

though pump and plumbing

systems are set and operat-

ing correctly

Plumbing Problems

11. Flow to one boom section is

different than flow to other

boom sections (as con-

firmed by catching flows of

each nozzle).

12. Too much material is being

applied; rate is not as cali-

brated.

30