Locke TR-30 User Manual

Page 22

General Notes for Field Operation

1. Lubricate the sprayer as needed. Refer to “

Maintenance and Lubrication” section start-

ing on page 24.

2. When transporting the sprayer, do not exceed

20 mph and do not unnecessarily transport with

chemical in the tank. Fasten the level-float pin

in the lock position (if applicable) before folding

the boom and transporting it.

3. Make sure all tank shut off valves (except the

tank drain) are opened.

4. Calibrate sprayer with water only. Calibrate

with the sprayer tank half full of water. Refer to

Tee Jet Manual.

5. Adjust throttling valves on the solenoids and

the manual pressure adjustment valve.

6. Inspect and clean, if necessary, pump nozzles

and filter.

7. Make sure the material you wish to apply can

be used in your sprayer without causing dam-

age to the pump seal.

IMPORTANT

The Hy Pro pump supplied with your sprayer is not

designed for use with every application. Materials

containing solvents, paints or solutions containing

abrasives will damage the pump. If you are unsure

of your chemicals, consult your dealer for suitability

or your application.

8. Safely and carefully add the chemical to the

sprayer tank. Always wear protective equip-

ment when handling chemicals. See Personal

Safety Equipment in “Important Safety Infor-

mation” section starting on page 5. By low,

chemical containers must be rinsed three

times. The container should then be punctured

to prevent future use. An alternative is to jet-

rinse or pressure rinse the container. Follow

chemical manufacturer’s recommendations for

safe handling of chemicals.

9. Check the sprayer initially and periodically for

loose bolts, pins and hose clamps. Check the

hoses, pumps, valves and fittings for leaks.

10. Make sure that the hand wash tank is full of

clean water.

Preparing the Sprayer

NOTE

Refer to Plumbing Diagram on page 13 if you need

help identifying specific sprayer components.

1. Close drain valve, air clean out valve and filter

clean out valve.

2. Open tank and inspect interior for contaminating

materials.

3. If the sprayer is equipped with a pump drive en-

gine (in addition to the vehicle’s engine), check

fuel and oil levels.

4. Perform an electrical system check on the boom

solenoids and pressure control switch. The sole-

noid switches will emit an audible click when the

switch is opened or closed. The pressure control

valve will make noise when the pressure control

adjustment switch is engaged. If any part fails,

refer to “Troubleshooting” section starting on page

26. Turn all switches off when finished with this

step.

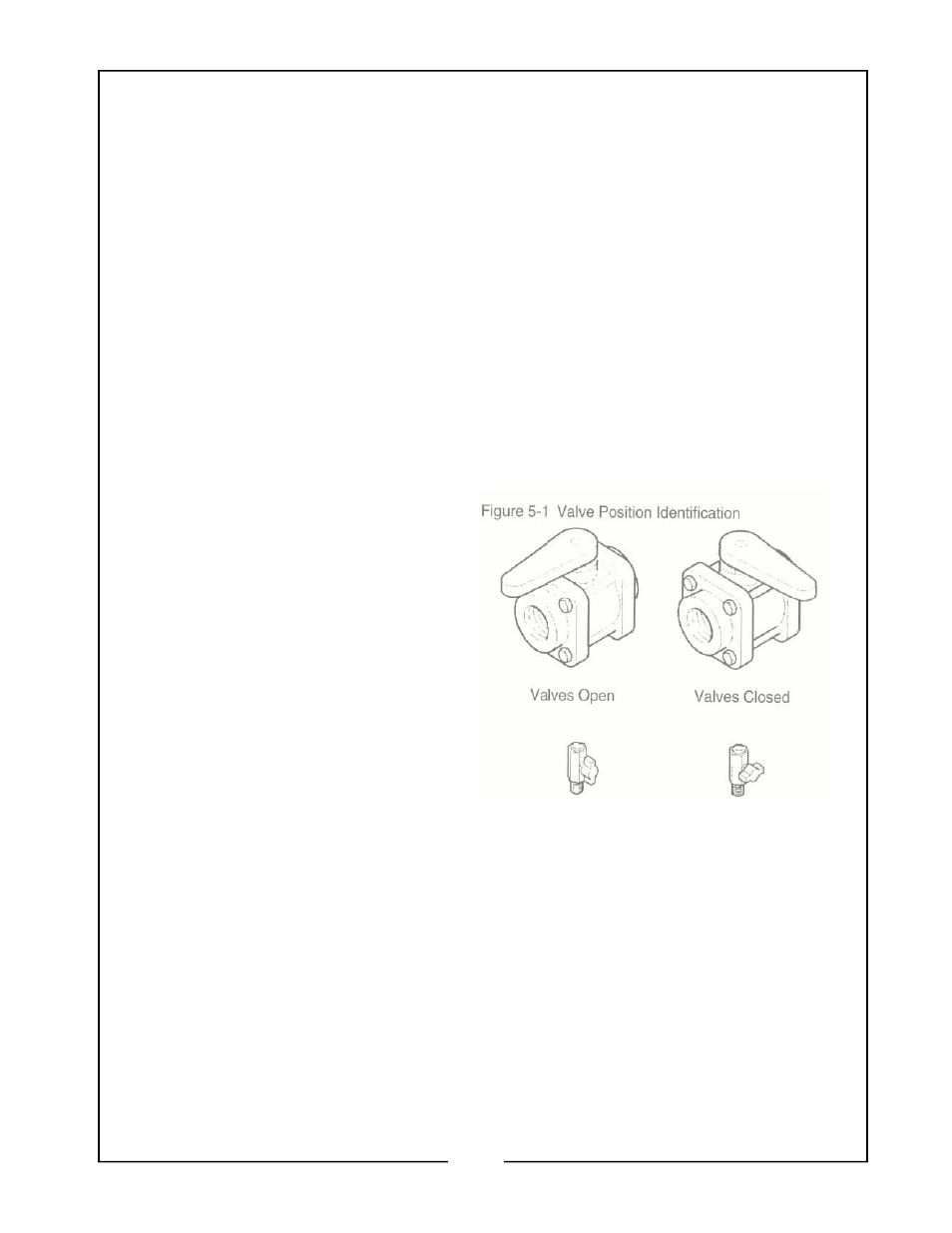

5. Open the pump suction valve.

6. Open the agitation valve. Refer to Figure 5-1 if

you are not sure whether a valve is open or

closed.

Figure 5-1 Valve Position Identification

7. Open the manual pressure control valve located

next to the electric pressure control valve.

8. Extend the boom sections. Check with the Boom

Operator’s manual if you are unfamiliar with the

operation of the boom. If using a level float boom,

remove the locking pin.

9. Some booms are equipped with a ball valve at

each nozzle. If so equipped, open these valves.

10. To operate the turf boom at a 15’ width, fold the

outer sections of the boom and close the ball

valves in front of the nozzles in the outer sections.

Note: this option is not present on all booms.

11. Attach water hose to the anti-siphon fill assembly.

Make sure the knife valve is open and fill the tank

at least 1/3 full, more if performing complete sys-

tems check.

21