Land Pride Primary Seeders PSN2096 User Manual

Page 32

Section 6: Maintenance & Lubrication

PSN2096 Primary Seeder 313-306M

30

5/29/13

Maintenance

Proper servicing and adjustment is the key to the long life

of any implement. With careful and systematic

inspection, you can avoid costly maintenance, time, and

repair.

After using and/or transporting your seeder for several

hours, check all bolts to be sure they are tight.

Replace any worn, damaged, or illegible safety labels by

obtaining new labels from your Land Pride Dealer.

!

WARNING

Always secure seeder in the up position with solid supports

before servicing the underside. Never work under equipment

supported by hydraulics. Hydraulics can drop equipment if

controls are actuated or if hydraulic lines burst. Either

situation can drop the seeder instantly even when power to the

hydraulics is shut off.

Drive System

Your Primary Seeder uses standard no. 40 roller chain

throughout its drive system. The drive system is simple

and designed for low maintenance.

Check all drive idler arms to insure that they are taking up

any excess chain slack and that the chain is not over-

tightened. Clean and lubricate all roller chains with chain

lubricant as needed.

Packing Rollers

The front and rear packing rollers should turn freely. If

they do not, investigate and remove the cause. The rear

roller assembly should be free to float up and down to

follow the field terrain. If it does not, investigate and

remove the cause.

Storage

It is good practice to clean off any dirt or grease that may

have accumulated on the seeder and moving parts at the

end of each working season and when your seeder will

not be used for several days.

1.

Be sure that the seed box is completely cleaned

before storing. It is best to do this while still hooked to

the tractor.

a. Scoop out any large quantities of seed left in the

box. Finish by using a small broom or vacuum

sweeper.

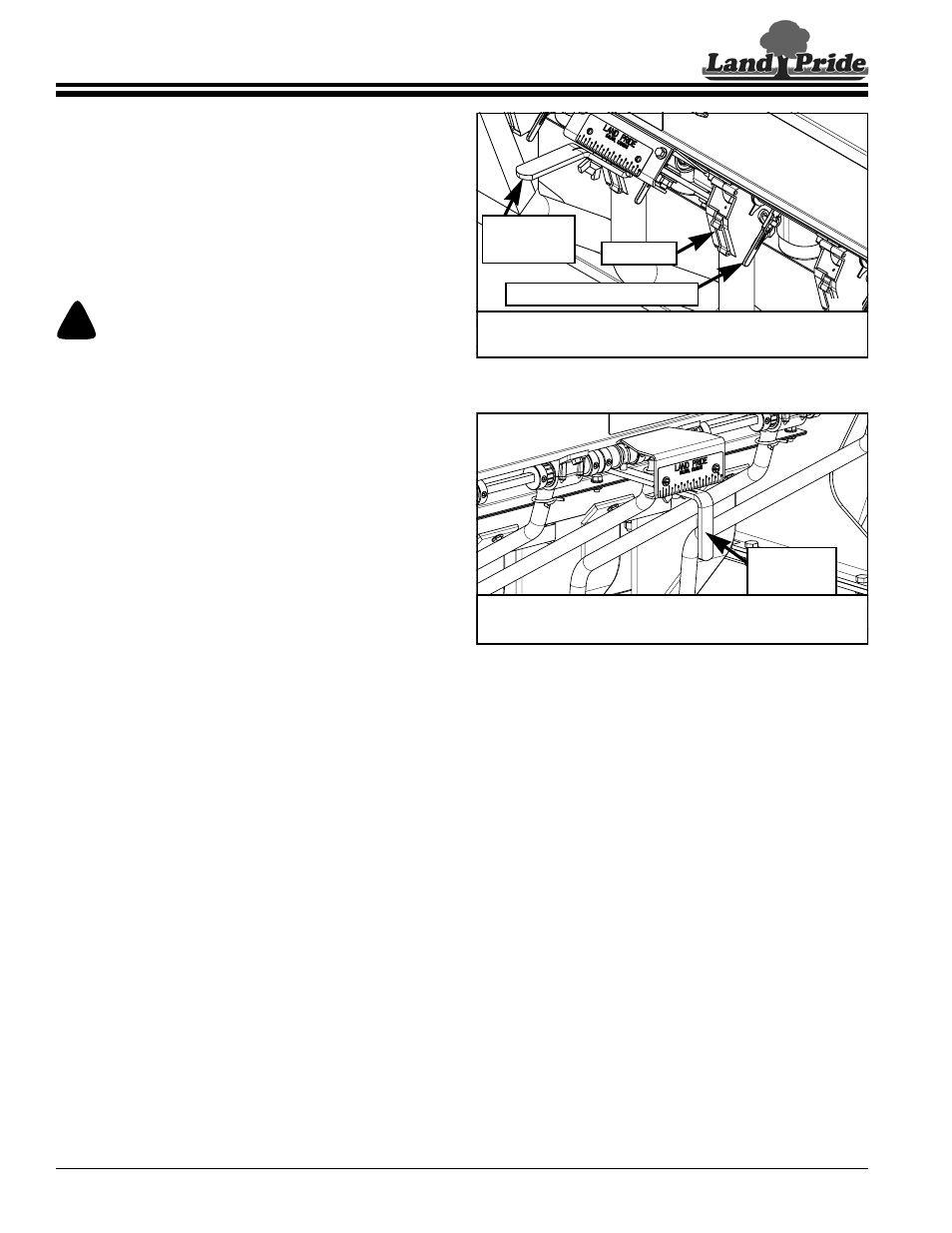

Refer to Figure 6-1 & Figure 6-2:

b. Move Standard Seeds Box & Small Seeds Box

rate adjustment lever(s) all the way to the right to

fully open seed cups.

c. Lower four position door handles to the lowest

position at each Small Seeds Box seed cup.

d. Run seeder over the ground to power the seed

cups to remove out-of-reach seeds.

e. Make a final sweep or vacuum the seed cups to

finish the cleaning job.

Section 6: Maintenance & Lubrication

Standard Seeds Box Adjustment Levers

Figure 6-1

Small Seeds Box Clean Adjustment Lever

Figure 6-2

2.

Place Rear Roller Pin in Parking position. (See

Figure 3-4, page 18.)

3.

The square bore of the seed cup drive sprocket hub

should be oiled to prevent seizing. Squirt oil on to the

square feed cup shaft and move seed cup

adjustment lever back and forth in order to get the oil

back into the square.

4.

Lubricate all grease fittings and roller chains as

noted under Lubrication Points starting on page 31.

5.

When in storage, make sure rear roller pin is in

Parking position and then lower seeder with rollers

on a board or hard surface. Adjust tongue jack

support the hitch on the Pull Hitch Option.

6.

Repaint parts where paint is worn or scratched to

prevent rust.

7.

Replace all damaged or missing decals.

8.

Store the seeder inside if possible. Inside storage will

reduce maintenance and make for a longer seeder

life.

9.

Inspect seeder for loose, damaged, or worn parts

and adjust or replace if needed with genuine Land

Pride parts. Do not alter Land Pride equipment.

Altering equipment can hinder performance and/or

cause damage to the equipment.

27613

Four-Position Door Handle

Seed Rate

Adjustment

Lever

Seed Cup

DO NOT open cups to the widest position with seed

in the box unless complete clean out is desired.

27614

Seed Rate

Adjustment

Lever

DO NOT open cups to the widest position with seed

in the box unless complete clean out is desired.