0 chilled water models, 1 piping considerations, Hilled – Liebert Challenger ITR User Manual

Page 43: Ater, Odels, Piping considerations

Chilled Water Models

37

6.0

C

HILLED

W

ATER

M

ODELS

6.1

Piping Considerations

Manual shut-off valves should be installed at the supply and return lines to each unit. This will pro-

vide for routine service and emergency isolation of the unit.

Consideration of the minimum water temperature to be supplied from the chiller will determine if the

need exists to insulate supply and return lines. Insulation will prevent condensation on the supply

and return lines.

To provide for the emergency of water leaks and the consequences of sub-floor flooding, floor drains

should be provided with wet traps or a water detection system, such as a Liqui-tect, that is installed

near the base of the unit or below the elevated floor.

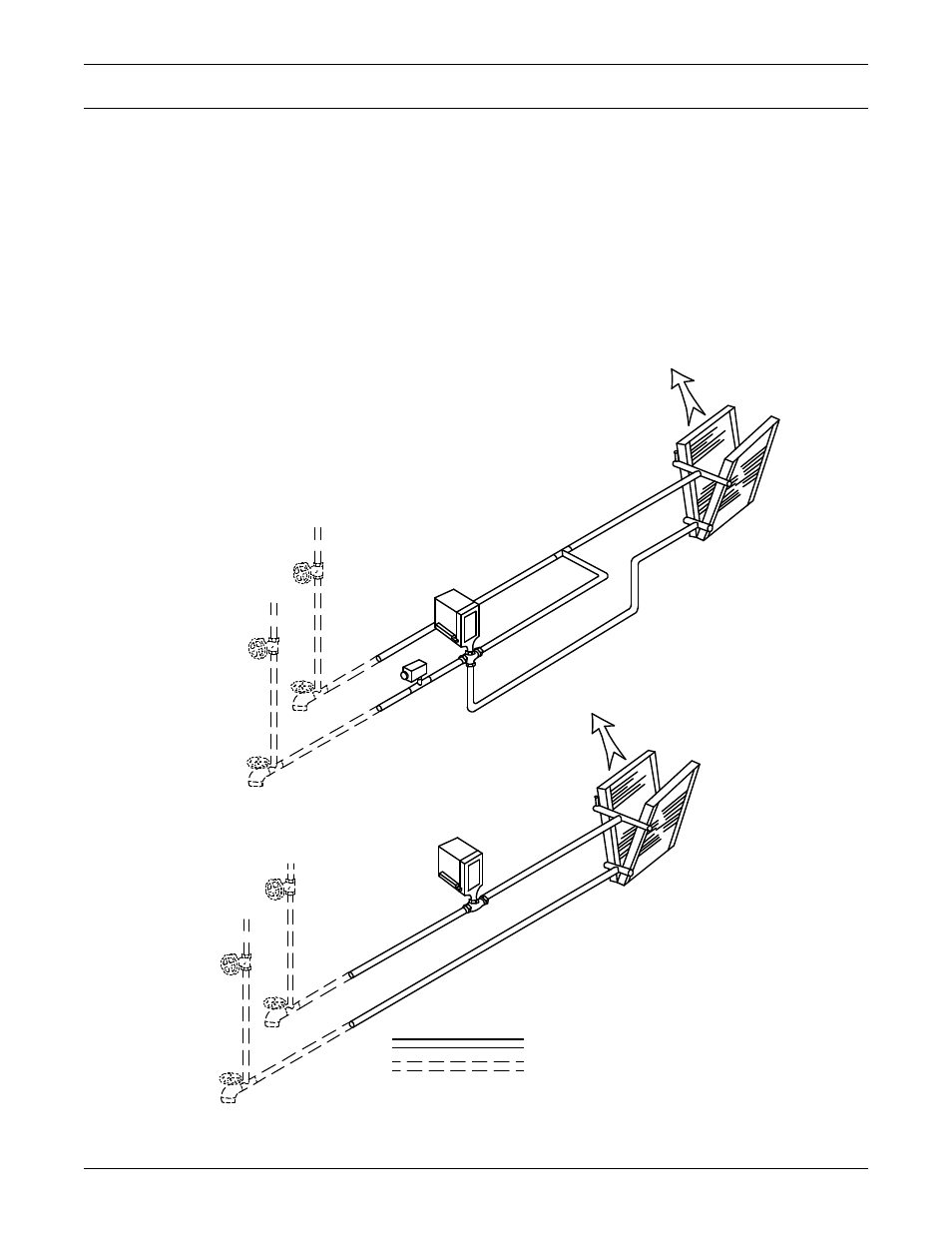

Figure 18 Chilled water general arrangement - horizontal flow (BR)

A

B

AB

FIELD PIPING

SL-11899

Pg. 5

Air

Flow

Chilled

Water

Coil

Bleed

Valve

Valve

Actuator

Valve

Flow

Switch

(optional)

Chilled

Water

Supply

Chilled

Water

Return

Hose

Bibs*

Hose

Bibs*

Shutoff

Valves*

3-WAY VALVE

Air

Flow

Bleed

Valve

Chilled

Water

Coil

Valve

Actuator

Shutoff

Valves*

Chilled

Water

Return

Chilled

Water

Supply

2-WAY VALVE

2-Way

Chilled

Water

Valve

SINGLE CIRCUIT SHOWN

*Components are not supplied by Emerson but

are recommended for proper circuit operation

and maintenance.

FACTORY PIPING

3-Way

Chilled

Water