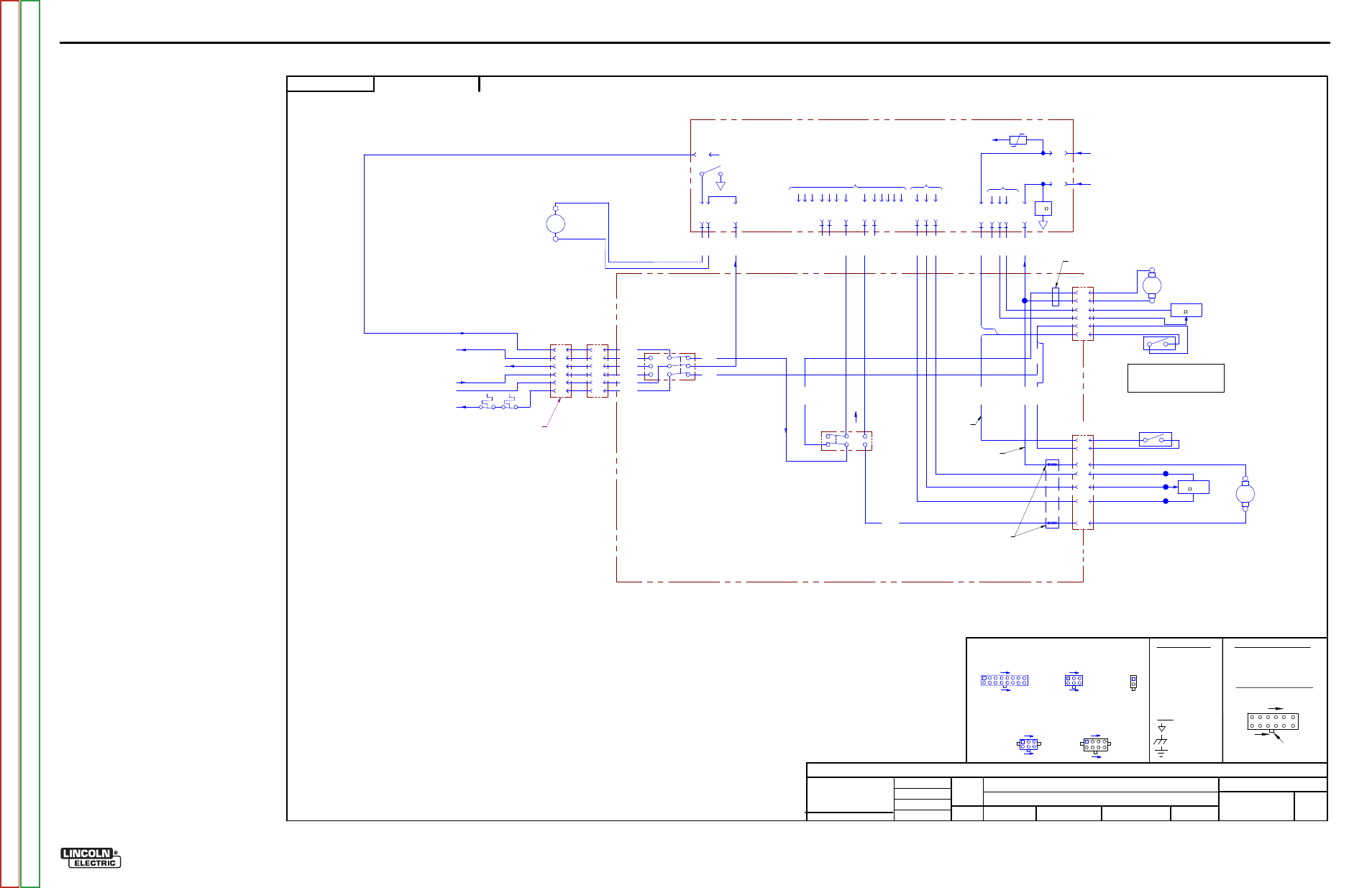

Electrical diagrams, Power mig® 215xt, Power mig 216 machine schematic – Lincoln Electric POWER MIG 11521 User Manual

Page 94

ElEcTrical DiaGramS

G-4

pOWEr miG® 215XT

SchEmaTic - cOmplETE machiNE - l12308-1 pG2

J1,

J14

CAVITY NUMBERING SEQUENCE

(COMPONENT SIDE OF P.C. BOARD)

J2

J3

9

PA

J4 (TRIGGER,

TACHOMETER,

MOTOR SIDE)

8

16

1

4

6

1

3

8

1

4

5

1

2

4

6

1

3

(NON-LEAD SIDE OF CONNECTOR)

LEAD COLOR CODE:

B-BLACK

G-GREEN

O-ORANGE

R-RED

U-BLUE

W-WHITE

Y-YELLOW

COMPONENT VALUE UNITS:

CAPACITOR: MFD/VOLTS

RESISTOR: OHMS/WATTS

CONNECTOR PIN NUMBERS:

VIEW OF CONNECTOR ON PC BOARD

1 2

6

7

12

LATCH

EX. 12 PIN CONNECTOR

LABELS:

COMMON

FRAME GROUND

EARTH GROUND

L12308-1

POWER MIG 216

MACHINE SCHEMATIC

NONE

L12308

DO NOT SCALE THIS DRAWING

EQUIPMENT TYPE:

SUBJECT:

UF

CRM41566

2

PAGE ___ OF ___

2

ENGINEERING CONTROLLED

MANUFACTURER:

No

THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION OWNED BY LINCOLN GLOBAL, INC. AND MAY NOT BE DUPLICATED, COMMUNICATED

TO OTHER PARTIES OR USED FOR ANY PURPOSE WITHOUT THE EXPRESS WRITTEN PERMISSION OF LINCOLN GLOBAL, INC.

PROPRIETARY &

CONFIDENTIAL:

REVISED PAGE 2.

t

MATERIAL TOLERANCE (" ") TO AGREE

WITH PUBLISHED STANDARDS.

ON ALL ANGLES IS ± .5 OF A DEGREE

ON 3 PLACE DECIMALS IS ± .002 in. (± 0.05 mm)

ON 2 PLACE DECIMALS IS ± .02 in. (± 0.5 mm)

UNLESS OTHERWISE SPECIFIED TOLERANCE:

MANUFACTURING TOLERANCE PER E2056

CHANGE DETAIL:

REFERENCE:

SCALE:

MATERIAL

DISPOSITION:

APPROVAL

DATE:

PROJECT

NUMBER:

DOCUMENT

NUMBER:

DOCUMENT

REVISION:

UNITS:

IF PRINTED

@ A2 SIZE

INCH

4/9/2010

cstuble

T. SPEAR

OBS

DRAWN BY:

ENGINEER:

CLEVELAND

APPROVED:

CONTROL:

C

L123

08

-1

2J

3

12

2A

CONTROL

P.C. BOARD

(SCHEMATIC G4414)

GAS SOLENOID -

1J

3

12

3A

1J

2

4J

2

11

7A

12

0C

2J

2

11

8A

LOCATEDON

CASEBACK

CONTROLSTHE

FUNCTIONALITYOF

THEMACHINE

3J5

3PB

6J5

6PB

1J5

1PB

5J5

5PB

4J5

4PB

2J5

2PB

V=8.7VDCWHENGASISFLOWING

COIL: 21.6 OHMS, 12VDCCOIL

SPOOL GUN

GAS SOLENOID

LOCATEDON

CASEBACK

**

3J

2

11

9A

6J

2

10

6E

GAS SOLENOID +

A

B

C

D

E

F

CLOSINGGUNTRIGGERMAKESBOTH

THESTANDARDGUNANDTHESPOOL

GUNSELECTRICALLYHOT!

SPOOL

GUN

MOTOR

MOTOR -

MOTOR +

2.2VDC@50 IN/MIN

20VDC@700IN/MIN

LOCATEDON

DIVIDERPANEL

INWIREDRIVE

COMPARTMENT

105C

105D

116C

106D

104E

104F

104G

105E

6-PIN

AMPHENOL

K2703-1 SPOOL GUN

ADAPTER PANEL

(TOSWITCHBETWEEN

SPOOLGUNAND

STANDARDGUN)

NORMALLYCLOSED(SHOWN

INSPOOL GUNPOSITION)

S2

TOGGLE

SWITCH

REFER TO L11543-1 FOR SPOOL GUN

ADAPTER PANEL INSTALLATION

INSTRUCTIONS.

SPOOL GUN TRIGGER

SPOOL GUN POT

11J1

12J1

.05

FROMSTANDARD

GUNTRIGGER

FROM112AFEED

MOTORNEGLEAD

FROMSTANDARDGUNTRIGGER

16J1 - POWERTOSTANDARDGASSOLENOIDANDUSED

FORSPOOL GUNDETECT(ATCONTROL BOARD)

MOTOR+SPEEDCONTROL

FROMCONTROL BOARD

TOSTANDARDFEEDMOTOR

+40 FROMDIODEDRIDGE

4J1 - TOCONTROL BOARD(TRIGGER)

THERMOSTAT

PTC

**

FOR MAGNUM SG AND MAGNUM 250LX

SPOOL GUNS OPERATION, REMOVE

MAGNUM 100SG ADAPTER PANEL (AND

HARNESS / SWITCH) FROM P5 OF MACHINE

HARNESS AND PLUG IN K2703-1 SPOOL GUN

HARNESS

5J1

WFS

5K

POT

A

B

C

D

E

F

SPOOL

GUN

MOTOR

MOTOR -

MOTOR +

1.7VDC@50 IN/MIN

24VDC@700IN/MIN

7-PIN

AMPHENOL

SPOOL GUN TRIGGER

SPOOL GUN POT

16

J1

4

12

9

6J

14

12

8

2J

14

14

J1

4

12

5A

12

7A

12

J1

4

G

12

6A

ALSO SEE

PAGE 1

SENSINGFOR7-PIN

SPOOL GUNTO

OPERATE

REMOTEWFS

FOR7-PIN

SPOOL GUN

MAX

TOROID

1 TOROID ON

BOTH LEADS

S3

SPOOL GUN

SELECTOR

SWITCH

10

5F

11

9B

12

0B

10

4H

105G

SPOOL GUN

MOTOR

COMMON

WFS

100K

POT

MAX

REMOTEWFS

FOR6-PIN

SPOOL GUN

SPOOL GUN

TRIGGER

COMMON

10

4G

THESSTANDARDFEEDMOTORCIRCUIT

ALSOISUSEDFORALL THESPOOL GUN

MOTORSWHENSELECTEDWITH

ADAPTERPANEL.

+

+

15

J1

4

13

J1

4

11

J1

4

10

J1

4

9J

14

4J

14

1J

14

3J

14

7J

14

8J

14

5J

14

5J

2

P.M.

P.M.

G-4

NOTE: This diagram is for reference only. It may not be accurate for all machines covered by this manual.