Reconnect procedure, Installation, Output connections – Lincoln Electric IDEALARC SVM136-A User Manual

Page 12

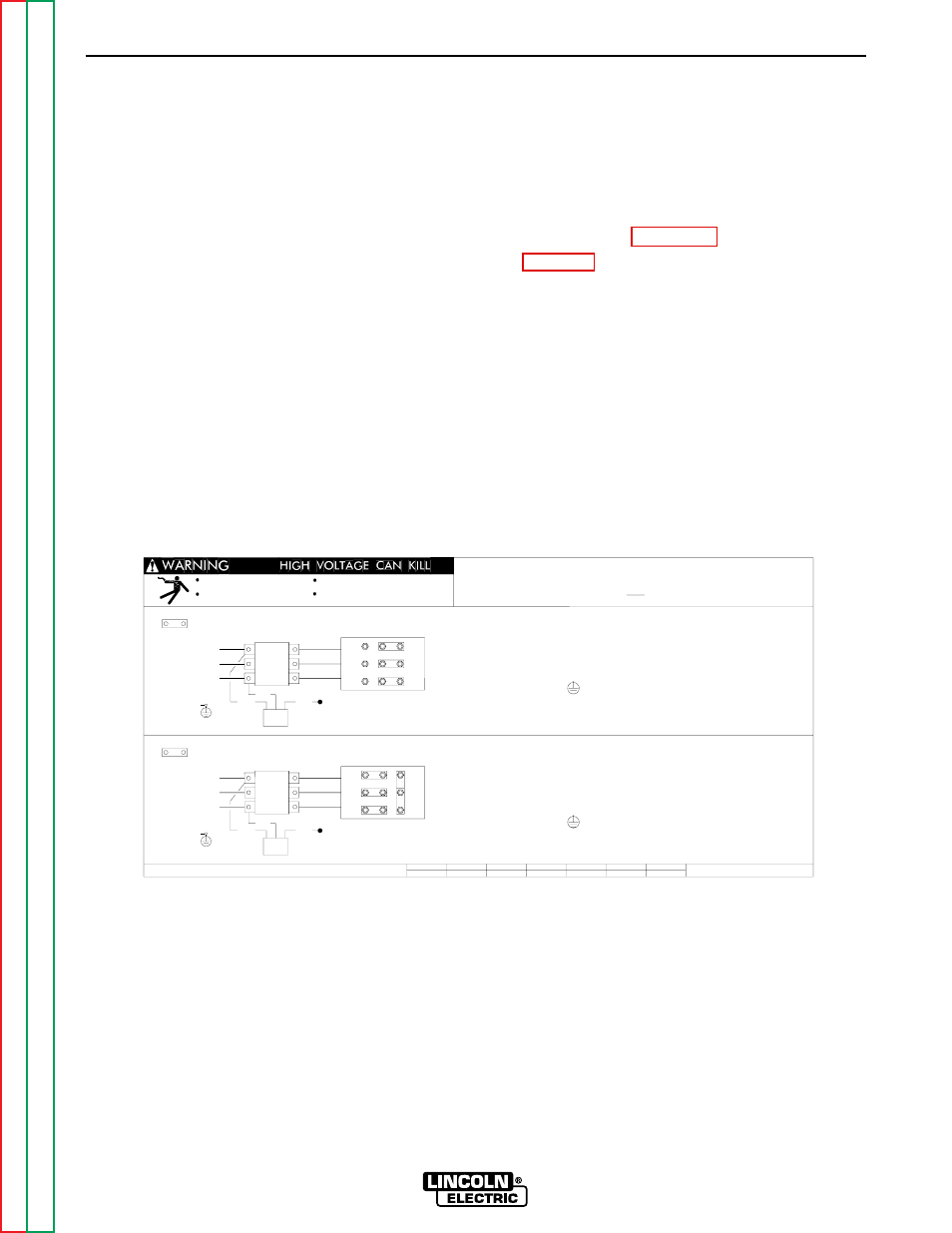

RECONNECT PROCEDURE

Multiple input voltage welders are shipped from the fac-

tory connected for the highest voltage listed on the

machine's rating plate. Before installing the welder, be

sure the reconnect panel is connected for the proper

voltage.

Failure to follow these instructions can cause immedi-

ate failure of components in the welder.

To reconnect a multiple voltage machine to a different

voltage, remove input power and change the position of

the jumper links on the reconnect panel. Follow the

input connection diagram, located on the inside access

panel cover, appropriate for your machine's input volt-

age. This same connection diagram is shown in Figure

A.4 below.

OUTPUT CONNECTIONS

CONNECT ELECTRODE AND WORK

LEADS TO OUTPUT TERMINALS

The output (welding) cables are connected to the out-

put terminals marked "+" and "-" . These 1/2" terminals

are located at the lower right and lower left corners of

the front panel. See

See

Table A.1 for recommended cable sizes for com-

bined lengths of electrode and work cables.

INSTALLATION

A-6

A-6

IDEALARC CV-400

FIGURE A.4

INPUT CONNECTION DIAGRAM FOR 230/460 VOLTS AC, 50/60 HZ

THE LINCOLN ELECTRIC CO., CLEVELAND OHIO U.S.A.

1. TURN OFF THE INPUT POWER USING THE DISCONNECT SWITCH AT THE FUSE BOX.

CONNECTION FOR LOWEST RATING PLATE VOLTAGE, 50 OR 60 HZ.

CONNECTION FOR HIGHEST RATING PLATE VOLTAGE, 50 OR 60 HZ.

CODES.

4. CONNECT TERMINAL MARKED TO GROUND PER LOCAL AND NATIONAL ELECTRIC

LEAST 600 VOLT INSULATION.

2. DISCONNECT AND INSULATE THE H2 LEAD TERMINAL WITH TAPE TO PROVIDE AT

5. MOUNT THE LINKS IN THE POSITIONS SHOWN WITH THE PROVIDED HEX NUTS.

USE. SECURE THE REMAINING HEX NUTS IN PLACE.

DOUBLE UP THE LINKS IN TWO OF THE POSITIONS TO SAVE THEM FOR FUTURE

5. MOUNT THE LINKS IN THE POSITIONS SHOWN WITH THE PROVIDED HEX NUTS.

LINK

1. TURN OFF THE INPUT POWER USING THE DISCONNECT SWITCH AT THE FUSE BOX.

CODES.

4. CONNECT TERMINAL MARKED TO GROUND PER LOCAL AND NATIONAL ELECTRIC

LEAST 600 VOLT INSULATION.

2. DISCONNECT AND INSULATE THE H3 LEAD TERMINAL WITH TAPE TO PROVIDE AT

3. CONNECT L1, L2 & L3 INPUT SUPPLY LINES AND H2 TRANSFORMER LEADS

TO THE INPUT SIDE OF THE CR1 CONTACTOR AS SHOWN.

3. CONNECT L1, L2 & L3 INPUT SUPPLY LINES AND H3 TRANSFORMER LEADS

TO THE INPUT SIDE OF THE CR1 CONTACTOR AS SHOWN.

INPUT SUPPLY CONNECTION DIAGRAM

Do not touch electrically live parts

Only qualified persons should install,

use or service this equipment

removed

servicing

Do not operate with covers

Disconnect input power before

NOTE: MACHINES ARE SHIPPED FROM FACTORY CONNECTED FOR OVER 300 VOLTS

DUAL VOLTAGE MACHINE

GND

H2

INPUT

LINES

L1

H1

L2

L3

{

CR1

V

U

W

CONTACTOR

H3

PILOT

TRANSF.

LINK

GND

H3

INPUT

LINES

L1

H1

L2

L3

{

CR1

V

U

W

CONTACTOR

H2

PILOT

TRANSF.

IMPORTANT: CHANGE LINK POSITIONS AND PILOT TRANSFORMER CONNECTIONS.