Installation, Electrode and work cable connections, Negative electrode polarity caution – Lincoln Electric POWER WAVE IM713-B User Manual

Page 12: Cable inductance, and its effects on pulse welding

A-5

INSTALLATION

POWER WAVE® 655/R

A-5

ELECTRODE AND WORK CABLE

CONNECTIONS

Connect a work lead of sufficient size and length (Per

Table 1) between the proper output terminal on the

power source and the work. Be sure the connection to

the work makes tight metal-to-metal electrical contact.

To avoid interference problems with other equipment

and to achieve the best possible operation, route all

cables directly to the work and wire feeder. Avoid

excessive lengths and do not coil excess cable.

Minimum work and electrode cable sizes are as follows:

TABLE 1 (For cable length up to 100 ft, or 30 meters)

CURRENT (60% Duty Cycle) MINIMUM COPPER

400 Amps

2/0 (67mm2)

500 Amps

3/0 (85mm2)

600 Amps

3/0 (85mm2)

When using inverter type power sources like the

Power Waves®, use the largest welding (electrode

and ground) cables that are practical. At least 2/0 cop-

per wire - even if the average output current would not

normally require it. When pulsing, the pulse current

can reach very high levels. Voltage drops can become

excessive, leading to poor welding characteristics, if

undersized welding cables are used.

NOTE: K1796 coaxial welding cable is recommended

to reduce the cable inductance in long cable lengths.

This is especially important when Pulse welding up to

350 amps.

CABLE INDUCTANCE, AND ITS EFFECTS

ON PULSE WELDING

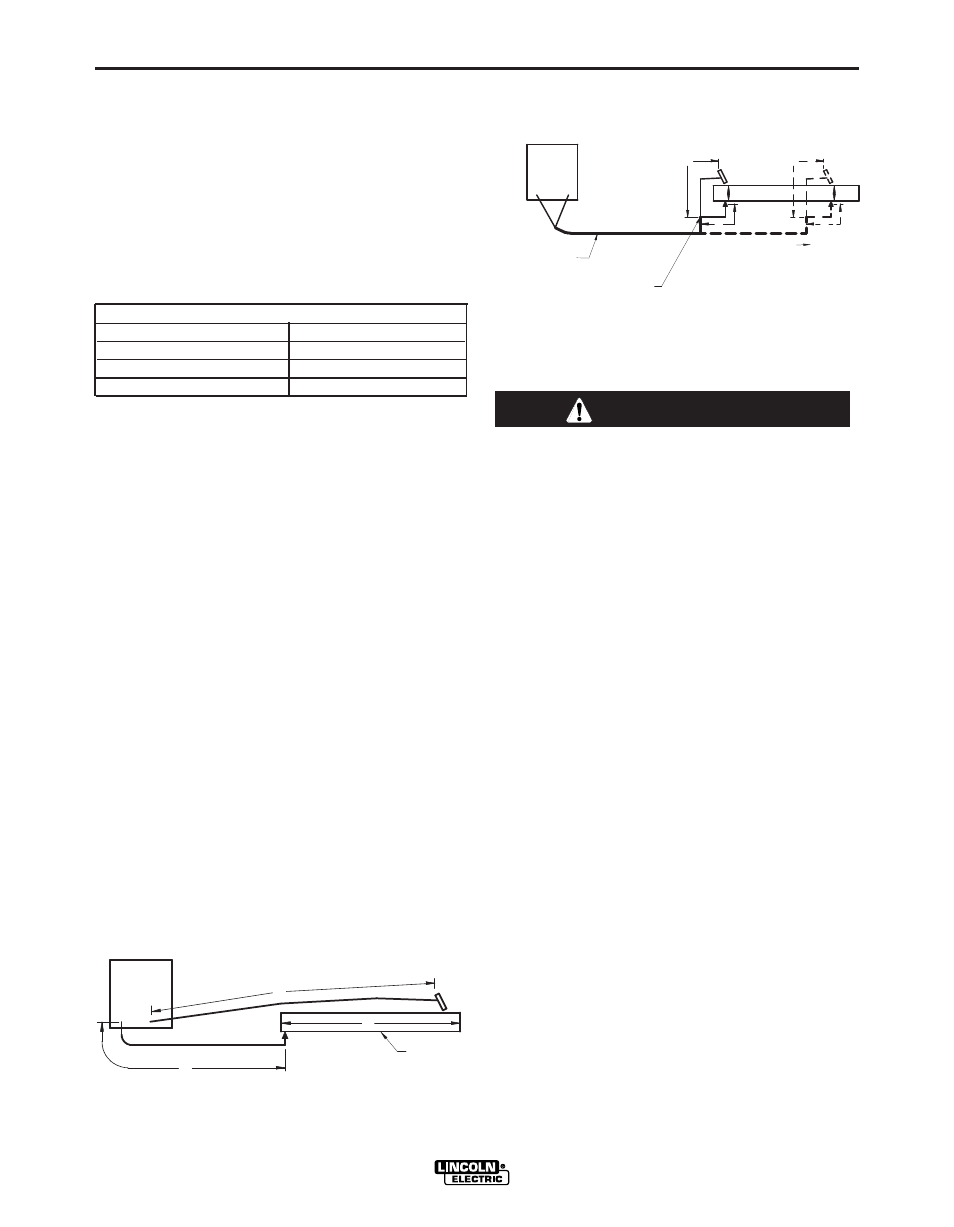

For Pulse Welding processes, cable inductance will

cause the welding performance to degrade. For the

total welding loop length less than ft.(m), traditional

welding cables may be used without any effects on

welding performance. For the total welding loop length

greater than ft.(m), the K1796 Coaxial Welding Cables

are recommended. The welding loop length is defined

as the total of electrode cable length (A) + work cable

length (B) + work length (C) (See Figure A.3).

For long work piece lengths, a sliding ground should

be considered to keep the total welding loop length

less than ft.(m). (See Figure A.4.)

FOR A DETAILED CONNECTION DIAGRAM USING

K1796 COAXIAL CABLE, SEE PAGE F-4.

When pulsing, the pulse current can reach very

high levels. Voltage drops can become excessive,

leading to poor welding characteristics, if under-

sized welding cables are used.

------------------------------------------------------------------------

Most welding applications run with the electrode being posi-

tive (+). For those applications, connect one end of the elec-

trode cable to the positive (+) output stud on the power

source (located beneath the spring loaded output cover near

the bottom of the case front). Connect the other end of the

electrode cable to the wire drive feed plate using the stud,

lockwasher, and nut provided on the wire drive feed plate.

The electrode cable lug must be against the feed plate. Be

sure the connection to the feed plate makes tight metal-to-

metal electrical contact. The electrode cable should be sized

according to the specifications given in the work cable con-

nections section. Connect a work lead from the negative (-)

power source output stud to the work piece. The work piece

connection must be firm and secure, especially if pulse weld-

ing is planned. Excessive voltage drops caused by poor work

piece connections often result in unsatisfactory welding per-

formance.

NEGATIVE ELECTRODE POLARITY

CAUTION

B

A

C

FIGURE A.3

POWER

WAVE

WORK

A

C

B

POWER

WAVE

FIGURE A.4

K1796 COAXIAL CABLE

MEASURE FROM END

OF OUTER JACKET OF

CABLE

C

A

B

WORK

SLIDING GROUND