Operation, Ln-15, Spring tension arm – Lincoln Electric LN-15 WIRE FEEDER SVM166-A User Manual

Page 20: Internal controls

LN-15

OPERATION

B-6

B-6

SPRING TENSION ARM

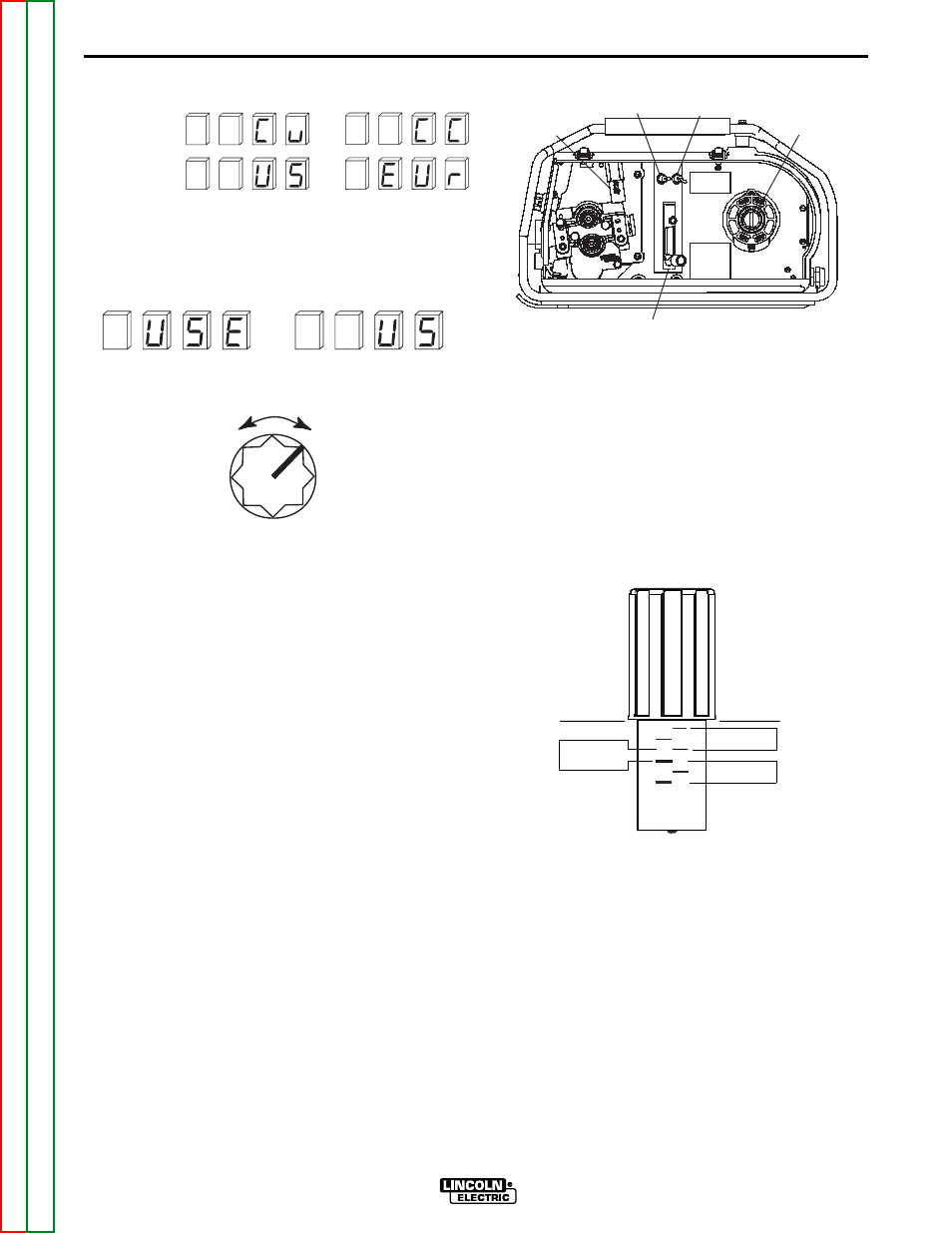

The pressure arm controls the amount of force the drive

rolls exert on the wire. Proper adjustment of both pressure

arm gives the best welding performance. For best results,

set both pressure arms to the same value.

Set the pressure arm as follows (See Figure B.2a):

Aluminum wires

between 1 and 3

Cored wires

between 3 and 4

Steel, Stainless wires

between 4 and 6

Figure B.2a

FLOWMETER

SPRING

TENSION

ARM

COLD FEED/

GAS PURGE

SWITCH

2 STEP/TRIGGER

INTERLOCK

SWITCH

SPINDLE

BRAKE

INTERNAL CONTROLS

(Figure B.2)

Rotate the WFS knob until the desired parameter is

displayed.

CV/CC Mode:

WFS Units:

2. Activate and release the GAS PURGE switch to

select the parameter. The present value will then

display in the right hand side of the display.

Example:

3. Rotate the WFS knob to change the parameter set-

ting.

CV/CC MODE:

• "CU" for Constant Voltage power sources

• "CC" for Constant Current power sources

WFS UNITS:

• "US" for in/min

• "Eur" for m/min

4. Press the GAS PURGE switch to save the setting.

The LN-15 will then return to the original "Press

Spin" mode in step 1.

5. To exit the "Press Spin" set-up mode, turn off power

to the LN-15, or simply wait 15 seconds and the LN-

15 will enter normal operation.

WFS

ALUMINUM

OUTERSHIELD

METALSHIELD

INNERS HIELD

STEEL

STAINLE SS

CORED WIRES

SOLID WIRES

6

1

3

2

5

4