6 blade spindle service, 7 troubleshooting – Locke MP-3132 User Manual

Page 17

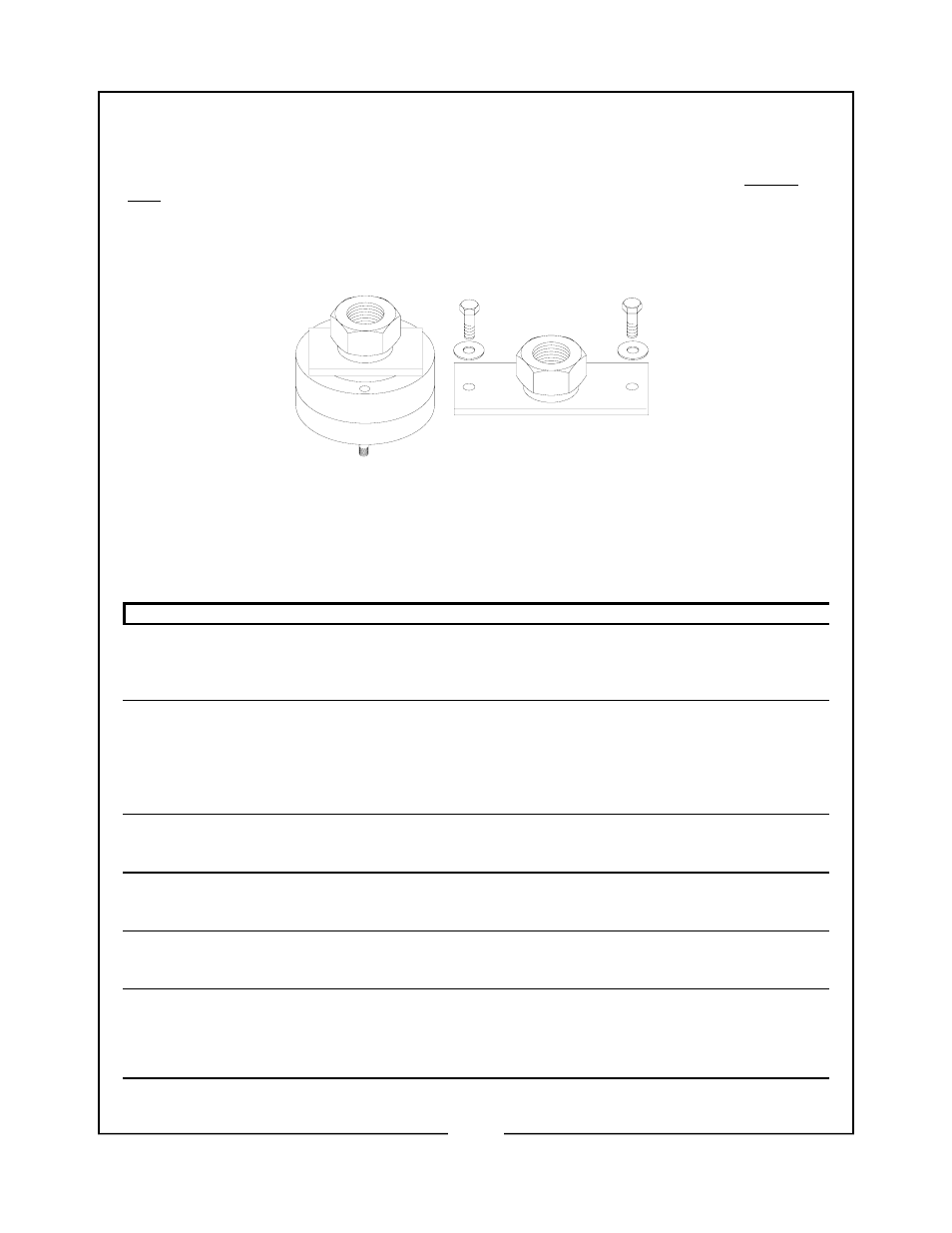

4-6 BLADE SPINDLE SERVICE

If shaft bearings or other parts require replacement, it is recommended that a Locke Turf dealer or other quali-

fied person service the blade spindle. If blade spindles must be disassembled, a special wrench kit must be

used to prevent damage to the assembly. This Wrench Kit (Part Number 50026073), including a sheave

wrench, carrier wrench and complete instructions, is available form Locke Turf. (Figure 4-6) Refer to “Blade

Spindle Service” at the rear of this manual.

Figure 4-6

Sheave Wrench

Carrier Wrench

4-7 TROUBLESHOOTING

Troubleshooting procedures are listed in Table 4-1 below. If the problem cannot be solved or replacement parts

are necessary, contact your authorized Locke Turf dealer. Please have ready your machine name, model num-

ber, serial number, purchase date and exact cause or description of the problem.

PROBLEM

PROBABLE CAUSE

REMEDY

Uneven Cut

Cutter not level side to side

or front to rear.

Belt slipping.

Worn or bent blade(s).

See SECTION III

Adjust belt per paragraph 4-3

Replace blade(s).

Streaking or Windrowing

Possible build-up of

material under cutter.

Cutter not level.

Worn blades.

Belt slipping.

Clean Cutter

See SECTION III

Replace blades.

Adjust belt per paragraph 4-

3.

Noisy Cutter

Loose components.

Low oil in gearbox.

Check all bolts for tightness.

Check oil per paragraph 4-2.

Rapid Blade Wear

(cutting edge)

Blade contacting ground.

Adjust cutting height to

eliminate ground contact.

Rapid Blade Wear

Cutter not being

Operated at rated PTO

speed.

Set tractor throttle for proper

PTO speed.

Use lower gear

Cutter Vibrating

Cutter not being operated at

rated PTO speed.

Blade(s) bent.

Foreign object wrapped

around spindle or blade.

Set tractor throttle for proper

PTO speed

Replace blades.

Remove object.

15