Accessories – Lincoln Electric MAXSA IM10024 User Manual

Page 36

C-14

ACCESSORIES

MAXsa™ 22 & 29 WIRE DRIVES

C-14

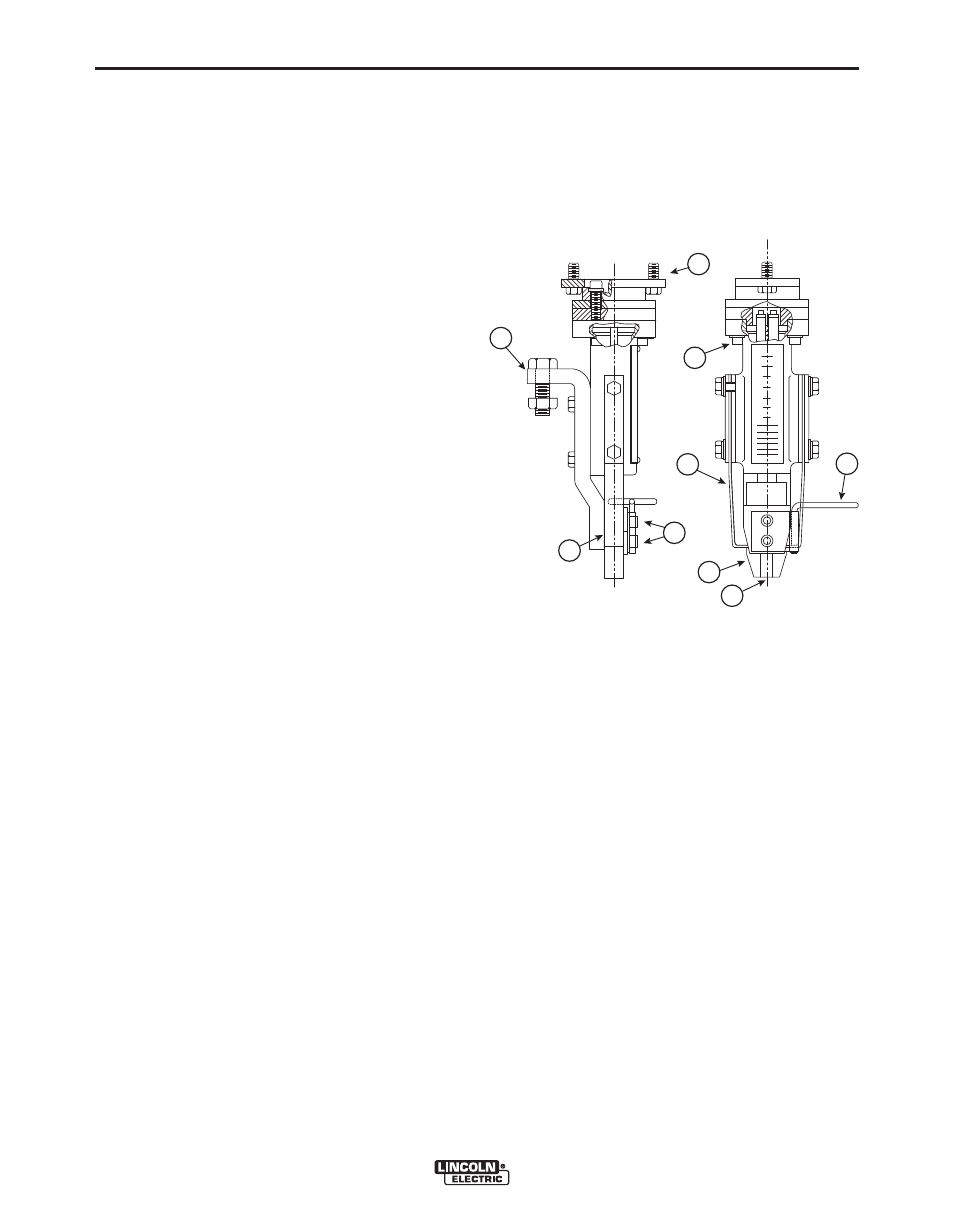

Nozzle Installation

(See Figure C.18)

1. install the new idle roll arm (C) using the pin and

set screw from the original assembly.

2. Replace the tension spring and screw and adjust

the tension screw to the proper line on the indica-

tor plate.

3. Insert one of the guide tubes (B) in the top of the

faceplate. Line up the holes in the guide tube

with the grooves in the drive rolls to insure proper

wire feed

4. Put the Dual Wire Straightener over the ingoing

guide tube and lock it down with the two “L”

shaped clamps

5. Place the other guide tube into the top of the

K225 Nozzle Assembly (F) and slide the guide

tube into the Wire Drive faceplate until the

mounting screws (1) can be started into the

tapped holes in the faceplate. Tighten both

screws.

NOTE:

For applications that require staggered or

cross seam wire placement rather than in-line,

the nozzle can be rotated by loosening the

two1/4-20 socket head screws (9) that hold

the nozzle to the mounting base. If the desired

angle cannot be obtained, remove the screws

and put them into alternate holes. Retighten

when properly adjusted.

6. Connect the weld cables of the proper size and

number to the copper bar (2). If using multiple

cables, use both sides of the bar.

7. Route the flux hose from the flux hopper to the

clip (3) on the K225 nozzle.

8. Spacing between the electrodes is maintained by

the center block which comes in three sizes. The

.50 “ and .625” center blocks come with the kit. A

.375” block is also available. See the parts list for

the part number. To change the center block,

See Figure A-30:

• Loosen both of the Pressure Springs (5)

• Remove the two Socket Head Screws (7)

• Put a small amount of graphite grease on

the screw threads and install the new copper

block.

• Replace the two screws and tighten securely

• Tighten the four screws holding the Pressure

springs

IMPORTANT

Make sure that the mating surface (8) between the

Center Block (4) and the Copper Bar (2). is bright,

clean and smooth. This junction carries the full weld

current.

Maintenance

The most extensive contact wear takes place on the

center contact block. The side pressure jaws are

made of a harder longer lasting material. Replace the

center block when there is no pressure on the wire

from the side contact jaws.

Make sure that the mating surface (8) between the

Center Block (4) and the Copper Bar (2). is bright,

clean and smooth. This junction carries the full weld

current.

FIGURE C.20

1

2

7

5

9

6

4

3

8