Accessories, C-13 – Lincoln Electric MAXSA IM10024 User Manual

Page 35

C-13

ACCESSORIES

MAXsa™ 22 & 29 WIRE DRIVES

C-13

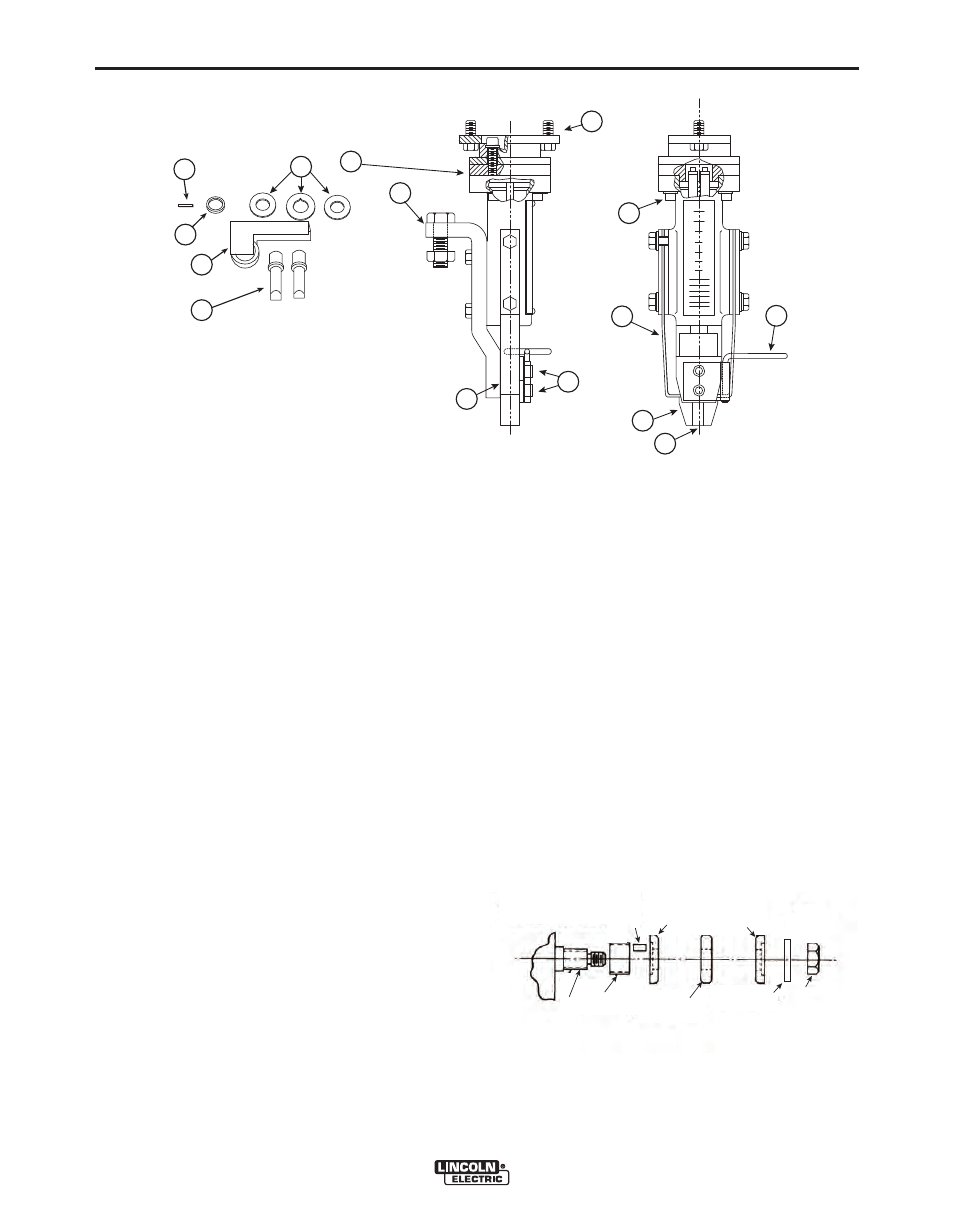

K225 SUBMERGED ARC TWINARC

®

KIT

Twin arc welding is a process where two wires of the

same size are fed through a nozzle by a single wire

drive. The K225 Twinarc Kit can be used to weld with

5/64”, 3/32” or 1/8” (2.0,2.4,or3.2mm) electrodes. Both

wires must be the same size.

The gear ratio of the MAXsa™ 22 & 29 WIRE DRI-

VES as shipped is 142:1. This may not provide

enough wire speed for the procedure. Conversion kits

for 95:1 or 57:1 ratio are also shipped with the

MAXsa™ 22 & 29 WIRE DRIVES units. See the

instructions included with those kits or in this manual

to change the gear ratio.

Each assembly comes with a wire reel, a reel brake,

shaft and mounting bracket, a dual wire straightener

and all of the wire drive components for the particular

wire size. See Figure C.18.

The Nozzle Assembly (F) has two spring loaded large

copper jaws (6) that press the electrodes against the

copper center block (4). This system provides good

elctrical contact and insures constant electrical stick-

out (E.S.O.) It also helps to maintain acceptable noz-

zle temperatures during welding.

INSTALLATION

1. Remove the following items from the standard

Feed Head.

• The wire straightener

• The nozzle assembly

• Both upper and lower guide tubes

• The drive rolls

• The idle roll assembly

NOTE:

The idle roll arm pivot pin is held in place by a

set screw that is accessed from the outgoing

surface of the faceplate.

• The tension spring assembly

`

• The Drive Roll Spacer

NOTE:

The set screw that holds the drive roll spacer

in place is accessible once the idle roll assem-

bly is removed.

2. Oil or grease the O.D. of the new shorter drive

roll spacer (E) and place it on the output shaft.

Push it back as far as it will go and tighten the

set screw.

3. Place the new longer key (F) in the keyway.

4. Place the outer, center and second outer drive

rolls (A) on the shaft. Replace the clamping

washer and the locking nut and tighten securely.

See Figure C.19.

FIGURE C.18 - K225 TWINARC® COMPONENTS

C

B

A

D

E

A - Drive Rolls

B - Guide Tubes

C - Idle Roll Arm

D - Drive Roll Spacer

E - Key

F - Nozzle Assembly

1

2

7

5

9

6

4

3

8

F

FIGURE C.19

Output

Shaft

Drive Roll

Spacer

Key

Outer Drive Rolls

Center

Drive Roll

Clamping

Washer

Locking

Nut