Accessories – Lincoln Electric MAXSA IM10024 User Manual

Page 24

C-2

ACCESSORIES

C-2

SUBMERGED ARC CONTACT

ASSEMBLIES

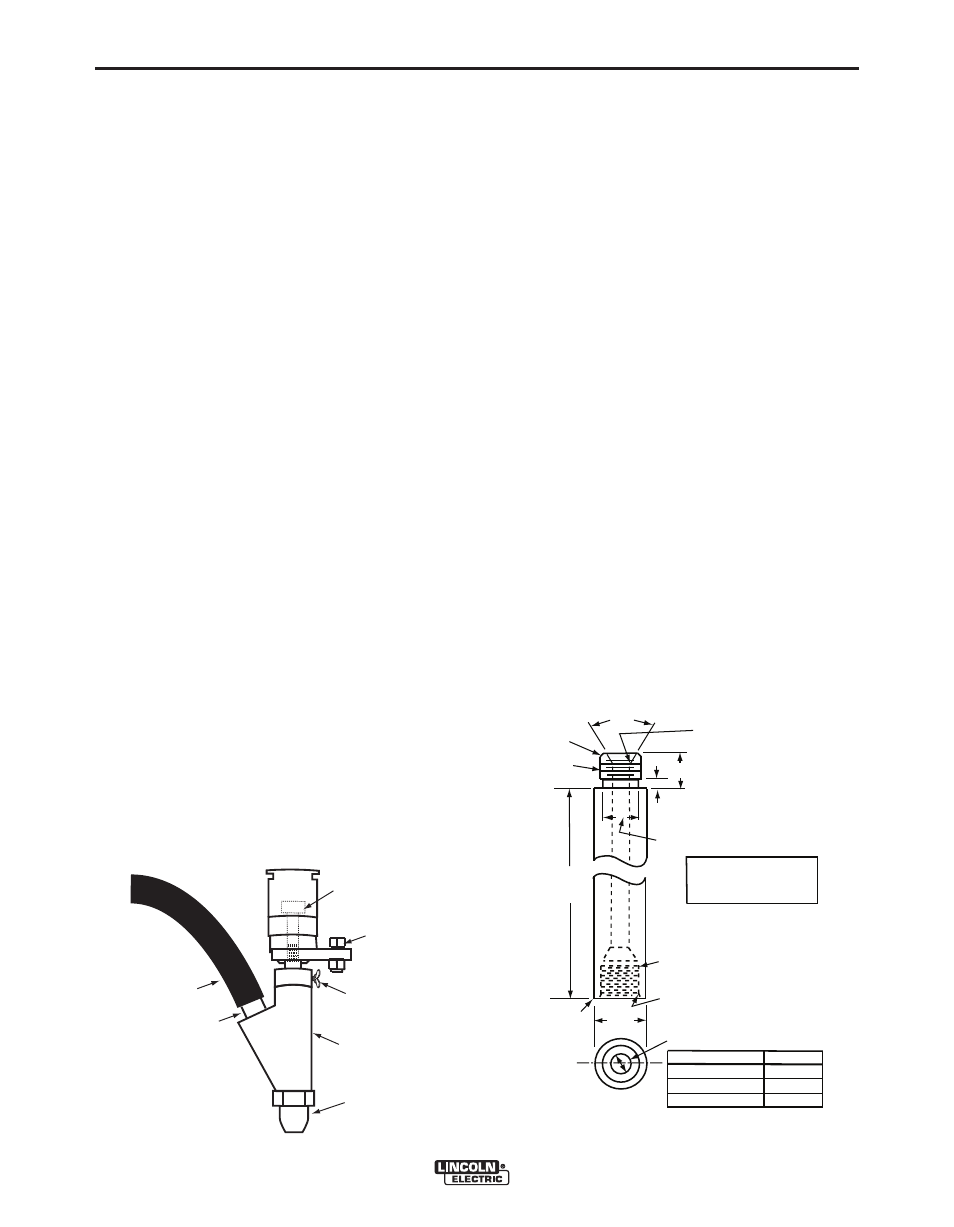

K231-[X/XX] CONTACT NOZZLE

The K231- [x/xx] is used for submerged arc weld-

ing with currents generally under 600 amps.

Higher currents can be used but result in some-

what faster tip wear. The outer flux cone deposits

flux around the arc for full coverage with mini-

mum flux consumption.

Contact tips for the electrode diameter specified

on the order are shipped with each nozzle. A dif-

ferent contact tip is required for each electrode

diameter used.

Installation

- Nozzles ordered for 3/32” (2.4 mm)

electrode include a liner and a contact tip

adapter. Screw the adapter into the end of the

nozzle and the contact tip into the adapter.

Insert the outgoing wire guide from the wire feed

head into the top of the K231 and install the

assembly in position on the bottom of the wire

feed head. Lock it in position using the two

clamps provided with the head.

Connect one end of the rubber flux hose to the

tube at the bottom of the flux hopper. Fit the

short copper tube in the other end of the rubber

hose then insert the copper tube into the hole in

the flux cone body. See Figure C.1

CAUTION

- Pushing the copper tube too far into

the flux cone body will cause a short

between the cone and nozzle if the

cone touches the work.

Connect the lug on the electrode cables from the

power source to the tab on the contact nozzle

and tighten the bolt and nut. See Figure C.1.

Operation

- DO NOT completely straighten the

electrode. A slight curvature is required in the

electrode to insure good electrical contact inside

the contact tip.

Maintenance

- Replace the contact tip when it

no longer provides accurate wire location or good

electrical contact. Rusty and dirty wire or exces-

sively high currents increase tip wear. Always

keep replacement tips in stock.

To replace the contact tip, first loosen the retain-

ing wing nut and remove the flux cone body.

Then unscrew the tip and replace it.

A special socket head screw holds the nozzle

body to the insulator. If the nozzle body becomes

loose, remove the nozzle from the head, tighten

the screw and reassemble nozzle.

Extensions

- The K231 nozzle can be extended

if necessary. Order part number S12003 for a 5”

(127mm) extension or make any length per draw-

ing in Figure C.2.

MAXsa™ 22 & 29 WIRE DRIVES

1/2”

1/8”

1/2”

60°

+

_ 2°

9/16-18

Class 2 Fit

1/32”x45°

Chamfer

As

Req’d

Break

Corner

3/4”

33/64”Drill 11/16” deep

9/16-18 Tap 9/16” deep

Class 2 Fit

1/32”x45°

Chamfer

“A” Dia. (See Table)

Remove Sharp

Corner

Wire Size

“A” Dim.

5/64-3/32(2.0-2.4mm) 1/8 (3.2mm)

1.8-5/32 (3.2-4.0mm) 3/16 (4.8mm)

3/16 -7/32(4.8-5.6mm) 1/4 (6.4mm)

Material - Hard Drawn

Copper or Heat Treatable

Copper Alloy

FIGURE C.2 - EXTENSION

FIGURE C.1 - K231

Weld Cable

Connection

Flux

Hose

Copper

Tube

Wing

Screw

Flux Cone

Body

Flux Cone

Socket Head

Screw