Accessories – Lincoln Electric MAXSA IM10024 User Manual

Page 30

C-8

ACCESSORIES

MAXsa™ 22 & 29 WIRE DRIVES

C-8

K285 Used in Horizontal Fillet Applications

1.

With K148 or K148/K149 combination -

After the

K285 has been attched to the nozzle body:

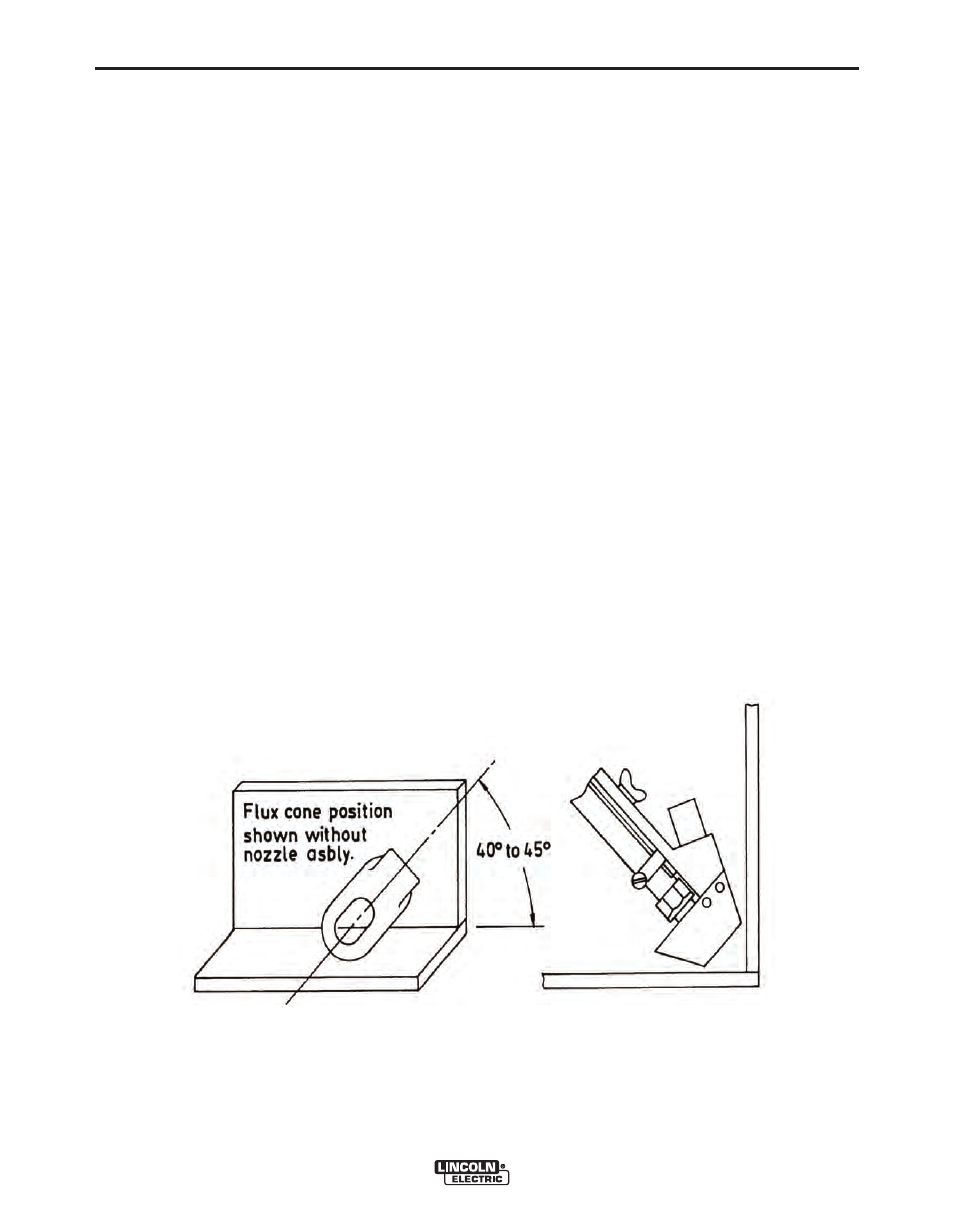

a. Set the head and nozzle to the desired electrode

angle.

b. Loosen the two hold down screws that hold the

nozzle to the faceplate and rotate the entire

assembly 40 to 45° and retighten the screws.

c. Feed the electrode to the proper stickout and

position it in the joint.

d. Slide the K285 flux cone dowm to about 1/8”

(3.0mm) away from both the vertical and horizon-

tal plates and tigten the wing screw. See Figure

C.12.

2.

With the K129 Tiny Twin-Arc® Nozzle -

After the

K285 has been attached to the nozzle body:

a. Set the head and nozzle to the desired electrode

angle.

b. Feed the electrode theough the tips to the proper

stickout and place the nozzle into the welding

position.

c. Loosen the K285 hose clamps and rotate the flux

cone unit about 40 to 45° and retighten the

clamps.

d. Slide the K285 flux cone dowm to about 1/8”

(3.0mm) away from both the vertical and horizon-

tal plates and tigten the wing screw. See Figure

C.12.

K285 in Deep Narrow Gap Applications

For narrow, deep groove welds it may be necessary to

remove the copper cone from the moveable arm of

the K285

NOTE:

In Horizontal fillet pplications, the flux hopper

will not function properly if fastened to the

faceplate of the wire drive. Mount the Flux

hopper directly above the K285 flux entry

point. Flux hose angles should be no greater

than 35° to ensure good flux flow from the

hopper to the cone.

FIGURE C.12 - K285 IN HORIZONTAL FILLET APPLICATION