Troubleshooting – Lochinvar 1.3 User Manual

Page 49

3

Troubleshooting

(continued)

49

Service Manual

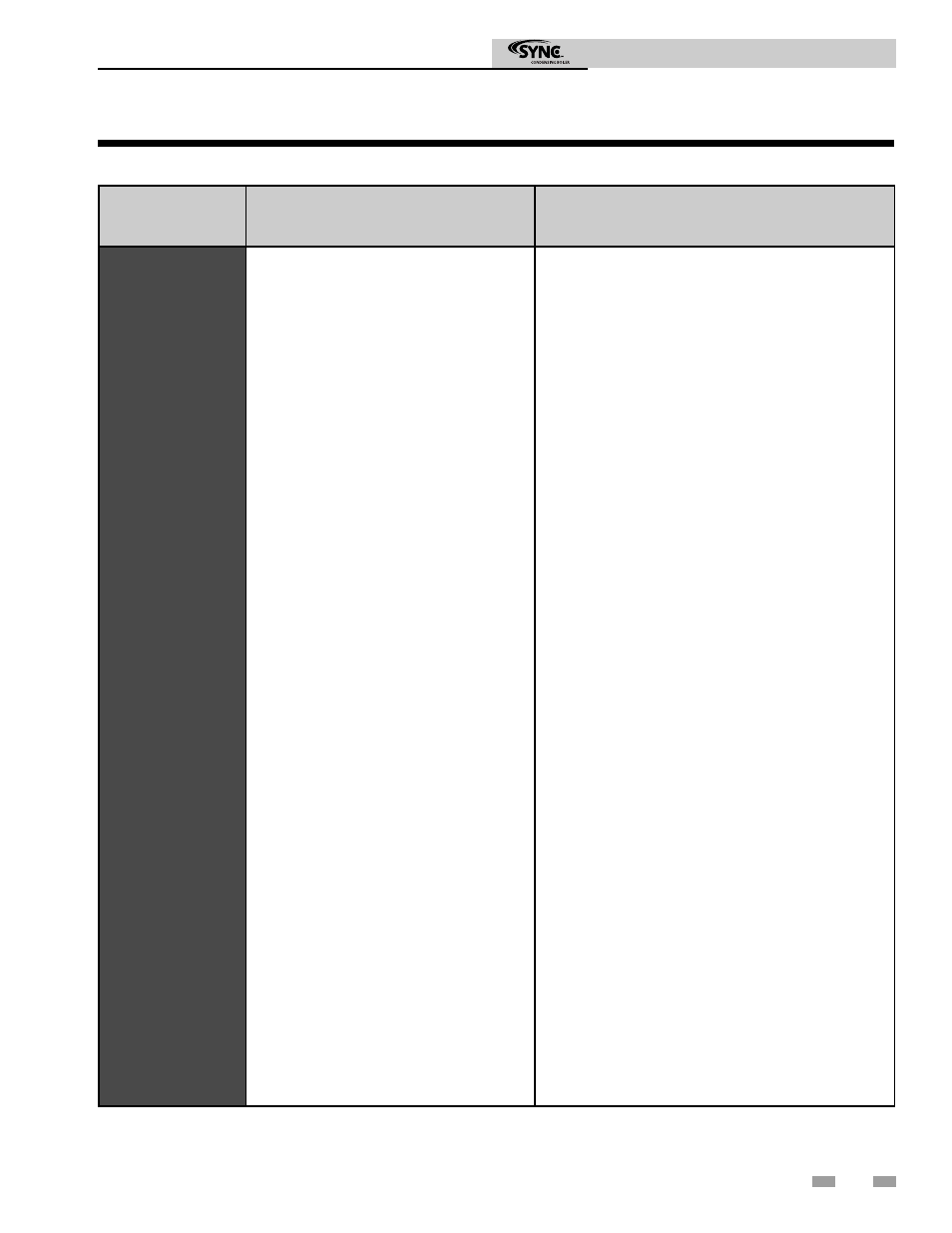

Table 3F (continued from previous page) Troubleshooting Chart - Fault Messages Displayed on Boiler Interface

FAULT

DESCRIPTION

CORRECTIVE ACTION

Flame Lost

While Running

(will require a manual

reset once the

condition has been

corrected. Press the

RESET button on the

display to reset.)

The unit was running and lost the flame

signal. This condition occurred twice .

• Inspect spark electrode and associated wiring for

damage and connection. Reference page 39 of this

manual for removal and cleaning procedures.

Replace if necessary.

• Check for proper electrical grounding of unit.

• Check incoming supply gas pressure. Natural gas

pressures should be between 4 -

14 inches w.c.

(1.0 - 3.5 kPa) and LP gas pressures should be

between 8 - 14 inches w.c. (2.0 - 3.2 kPa).

Refer to Section 6 - Gas Connections of the SYNC

Installation and Operation Manual for detailed

information concerning the gas supply.

• Verify that the plastic hose from the gas valve to the air

inlet is connected and is not damaged.

• Verify that the vent/air intake pipes are installed

correctly and there are no obstructions.

• Check for 24 VAC to the gas valve at the 2-pin

connection on the side of the main control board

during the ignition attempt. If no voltage is present,

replace the main control board.

• If 24 VAC is present at the main control board, check

the wiring between the main control board and the gas

valve. Replace the wiring if necessary. Do not

disconnect the wiring from the gas valve and attempt

to measure voltage at that point. The main control

board can detect if the gas valve is not connected and

will display the Gas Valve / Connection fault.

• If 24 VAC is present, check the outlet of the valve to

ensure the valve is flowing gas. With a manometer

connected to the outlet tap of the gas valve, when the

unit is in the prepurge period, there should be a

negative pressure present. When the valve is

energized a change in pressure should occur. If the

pressure change does not occur, the gas valve is not

opening. Replace the gas valve.

• Inspect flame sensor and associated wiring.

Reference page 39 of this manual for removal and

cleaning procedures. Replace if necessary.

• Inspect the burner. Reference page 39 of this manual

for removal and cleaning procedures. Replace if

necessary.

• Replace the main control board.