Kawasaki 840074-1HR User Manual

Page 6

9

S

SY

YM

MB

BO

OL

LS

S

IIM

MP

PO

OR

RT

TA

AN

NT

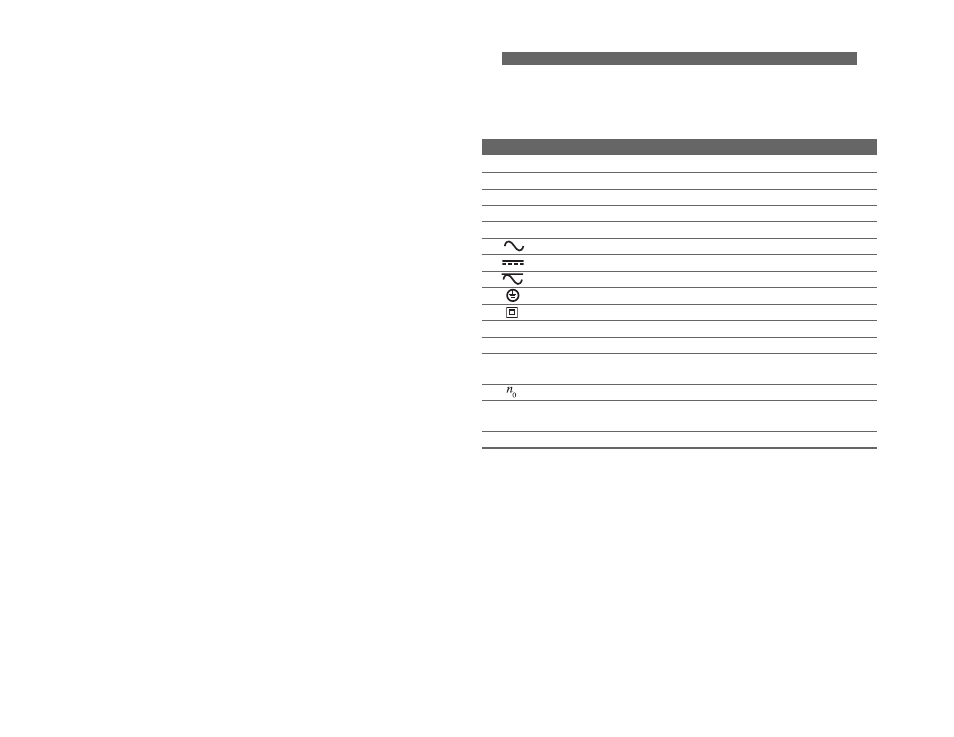

T:: Some of the following symbols may be used on your tool. Please

study them and learn their meaning. Proper interpretation of these symbols will

allow you to operate the tool better and safer.

S

SY

YM

MB

BO

OL

L

N

NA

AM

ME

E

E

EX

XP

PL

LA

AN

NA

AT

TIIO

ON

N

V

Volts

Voltage (Potential)

A

Amperes

Current

Hz

Hertz

Frequency (Cycles per Second)

W

Watt

Power

Kg

Kilograms

Weight

Alternating Current

Type of Current

Direct Current

Type of Current

Alternating or Direct Current

Type of Current

Earthing Terminal

Grounding Terminal

Class II Construction

Denotes Double Insulation

min

Minutes

Time

s

Seconds

Time

Diameter

Size of Drill Bits,

Grinding Wheels, etc.

No load speed

No-load Rotational Speed

.../min

Revolutions per Minute

Revolutions, Surface Speed,

Strokes, etc. per Minute

1,2,3, …

Ring Selector Settings

Speed, Torque or Position Settings

If the blade becomes twisted or misaligned in the cut, the teeth at the back edge of the

blade can dig into the top surface of the wood causing the blade to climb out of the kerf

and jump back toward the operator.

Kickback is the result of tool misuse and/or incorrect operating procedures or

conditions and can be avoided by taking proper precautions as given below:

M

Ma

aiin

ntta

aiin

n a

a ffiirrm

m g

grriip

p o

on

n tth

he

e ssa

aw

w a

an

nd

d p

po

ossiittiio

on

n yyo

ou

urr b

bo

od

dyy a

an

nd

d a

arrm

m iin

n a

a w

wa

ayy tth

ha

att

a

allllo

ow

wss yyo

ou

u tto

o rre

essiisstt K

KIIC

CK

KB

BA

AC

CK

K ffo

orrcce

ess.. KICKBACK forces can be controlled by the

operator, if proper precautions are taken.

W

Wh

he

en

n b

blla

ad

de

e iiss b

biin

nd

diin

ng

g,, o

orr w

wh

he

en

n iin

ntte

errrru

up

pttiin

ng

g a

a ccu

utt ffo

orr a

an

nyy rre

ea

asso

on

n,, rre

elle

ea

asse

e tth

he

e

ttrriig

gg

ge

err a

an

nd

d h

ho

olld

d tth

he

e ssa

aw

w m

mo

ottiio

on

nlle

essss iin

n tth

he

e m

ma

atte

erriia

all u

un

nttiill tth

he

e b

blla

ad

de

e cco

om

me

ess tto

o a

a

cco

om

mp

plle

ette

e sstto

op

p.. N

Ne

evve

err a

atttte

em

mp

ptt tto

o rre

em

mo

ovve

e tth

he

e ssa

aw

w ffrro

om

m tth

he

e w

wo

orrkk o

orr p

pu

ullll tth

he

e ssa

aw

w

b

ba

acckkw

wa

arrd

d w

wh

hiille

e tth

he

e b

blla

ad

de

e iiss iin

n m

mo

ottiio

on

n o

orr K

KIIC

CK

KB

BA

AC

CK

K m

ma

ayy o

occccu

urr.. Investigate and

take corrective actions to eliminate the cause of blade binding.

W

Wh

he

en

n rre

esstta

arrttiin

ng

g a

a ssa

aw

w iin

n tth

he

e w

wo

orrkk p

piie

ecce

e,, cce

en

ntte

err tth

he

e ssa

aw

w b

blla

ad

de

e iin

n tth

he

e kke

errff a

an

nd

d

cch

he

ecckk tth

ha

att tte

ee

etth

h a

arre

e n

no

ott e

en

ng

ga

ag

ge

ed

d iin

ntto

o tth

he

e m

ma

atte

erriia

all.. If saw blade is binding, it may

walk up or KICKBACK from the work piece as the saw is restarted.

S

Su

up

pp

po

orrtt lla

arrg

ge

e p

pa

an

ne

ellss tto

o m

miin

niim

miizze

e tth

he

e rriisskk o

off b

blla

ad

de

e p

piin

ncch

hiin

ng

g a

an

nd

d K

KIIC

CK

KB

BA

AC

CK

K.. Large

panels tend to sag under their own weight. Supports must be placed under the panel

on both sides, near the line of cut and near the edge of the panel.

D

Do

o n

no

ott u

usse

e d

du

ullll o

orr d

da

am

ma

ag

ge

ed

d b

blla

ad

de

e.. Unsharpened or improperly set blades produce

narrow kerf causing excessive friction, blade binding and KICKBACK.

B

Blla

ad

de

e d

de

ep

ptth

h a

an

nd

d b

be

evve

ell a

ad

djju

ussttiin

ng

g llo

occkkiin

ng

g lle

evve

errss m

mu

usstt b

be

e ttiig

gh

htt a

an

nd

d sse

eccu

urre

e b

be

effo

orre

e

m

ma

akkiin

ng

g ccu

utt.. If blade adjustment shifts while cutting, it will cause binding and KICK-

BACK.

U

Usse

e e

exxttrra

a cca

au

uttiio

on

n w

wh

he

en

n m

ma

akkiin

ng

g a

a “

“P

Po

occkke

ett C

Cu

utt”

” iin

ntto

o e

exxiissttiin

ng

g w

wa

allllss o

orr o

otth

he

err b

blliin

nd

d

a

arre

ea

ass.. The protruding blade may cut objects that can cause KICKBACK.