Troubleshooting guide start up conditions – Kenmore 153.331572 User Manual

Page 32

32

TROUBLESHOOTING GUIDE

Start Up Conditions

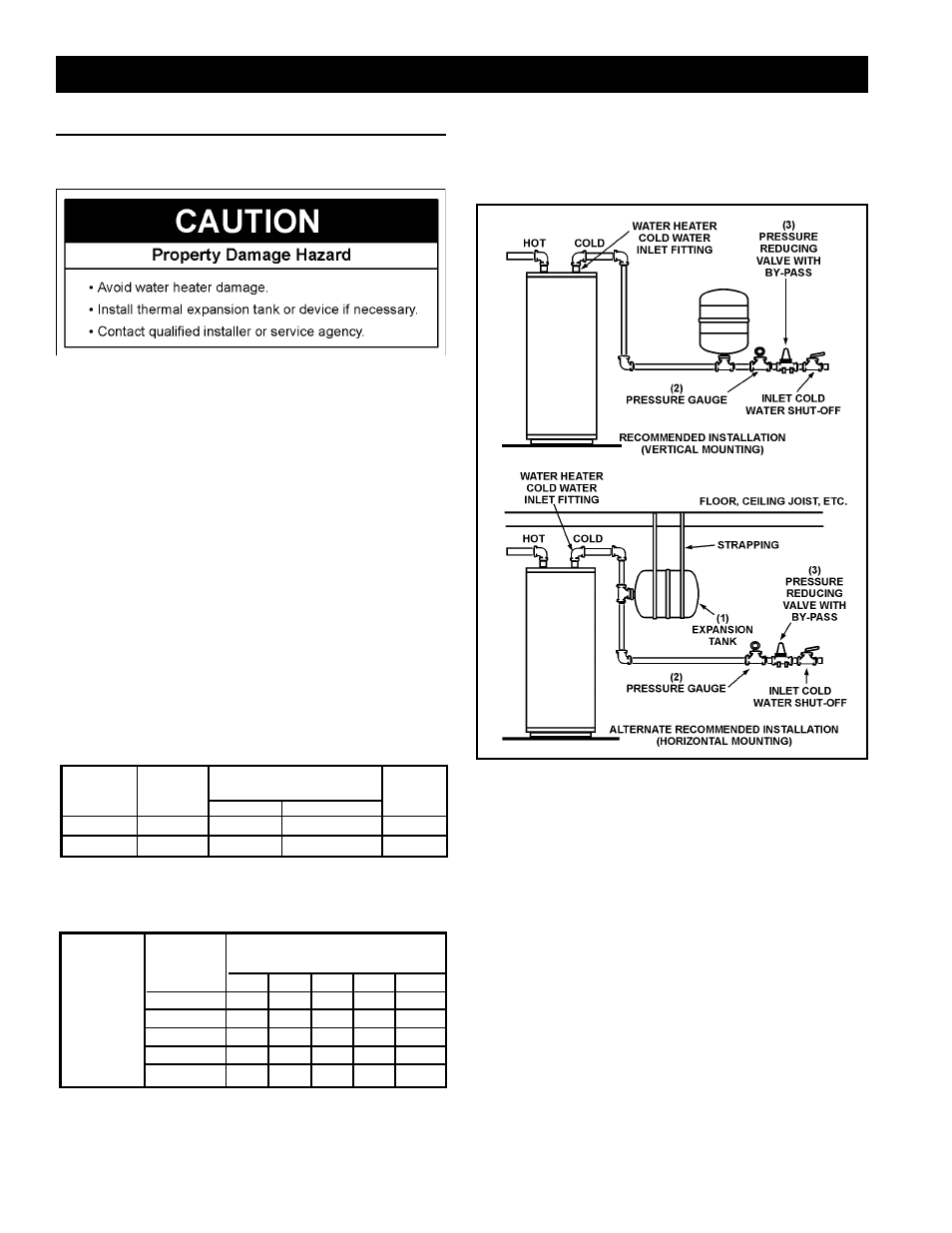

Thermal Expansion

As water is heated, it expands (thermal expansion). In a closed

system, the volume of water will grow. As the volume of water

grows, there will be a corresponding increase in water pressure

due to thermal expansion. Thermal expansion can cause

premature tank failure (leakage). This type of failure is not

covered under the limited warranty. Thermal expansion can also

cause intermittent temperature-pressure relief valve operation:

water discharged from the valve due to excessive pressure

build up. The temperature-pressure relief valve is not intended

for the constant relief of thermal expansion. This condition is not

covered under the limited warranty.

A properly sized thermal expansion tank should be installed

on all closed systems to control the harmful effects of thermal

expansion. Thermal expansion tanks are available from Sears

stores and through the Sears Service Centers. Contact the local

plumbing inspector, water supplier and/or the Sears Service

Center for assistance in controlling these situations. See

Figure 42.

Thermal Expansion Tank Specifi cations

Tank

Dimensions

Pipe

Model

Capacity in Inches

Fitting

Number In

Gallons Diameter

Length

On

Tank

153.331020

2

8 (203 mm) 12-3/4 (323 mm) 3/4” Male

153.331050

5

11 (279 mm) 14-3/4 (375 mm) 3/4” Male

TABLE 5

Expansion Tank Sizing Chart

Inlet* Water Heater Capacity (Gallons)

Water

Pressure 30 40 50 66 82

Expansion 40psi 2 2 2 5 5

Tank

50psi 2 2 2 5 5

Capacity 60psi 2 2 5 5 5

Needed 70psi 2 2 5 5 5

80psi 2 5 5 5 5

TABLE 6

*Highest recorded inlet water pressure in a 24 hour period or regulated

water pressure.

NOTE: Expansion tanks are pre-charged with a 40 psi air

charge. If the inlet water pressure is higher than 40 psi, the

expansion tank’s air pressure must be adjusted to match

that pressure, but must not be higher than 80 psi.

FIGURE 42.

Strange Sounds

Possible noises due to expansion and contraction of some

metal parts during periods of heat-up and cool-down do not

represent harmful or dangerous conditions.

Condensation causes sizzling and popping within the burner

area during heating and cooling periods and should be

considered normal. See “Condensation” section.

Draft Hood Operation

Check draft hood operation by performing a worst case

depressurization of the building. With all doors and windows

closed, and with all air handling equipment and exhaust fans

operating such as furnaces, clothes dryers, range hoods and

bathroom fans, a match flame should still be drawn into the draft

hood of the water heater with its burner firing. If the flame is not