Other information, N measuring principles, Nmeasuring principles – Konica Minolta Non-Contact 3D Digitizer Range7 User Manual

Page 22: Basic principle, High-speed image processing circuit, Time center of gravity and space center of gravity

20

Other Information

n

Measuring Principles

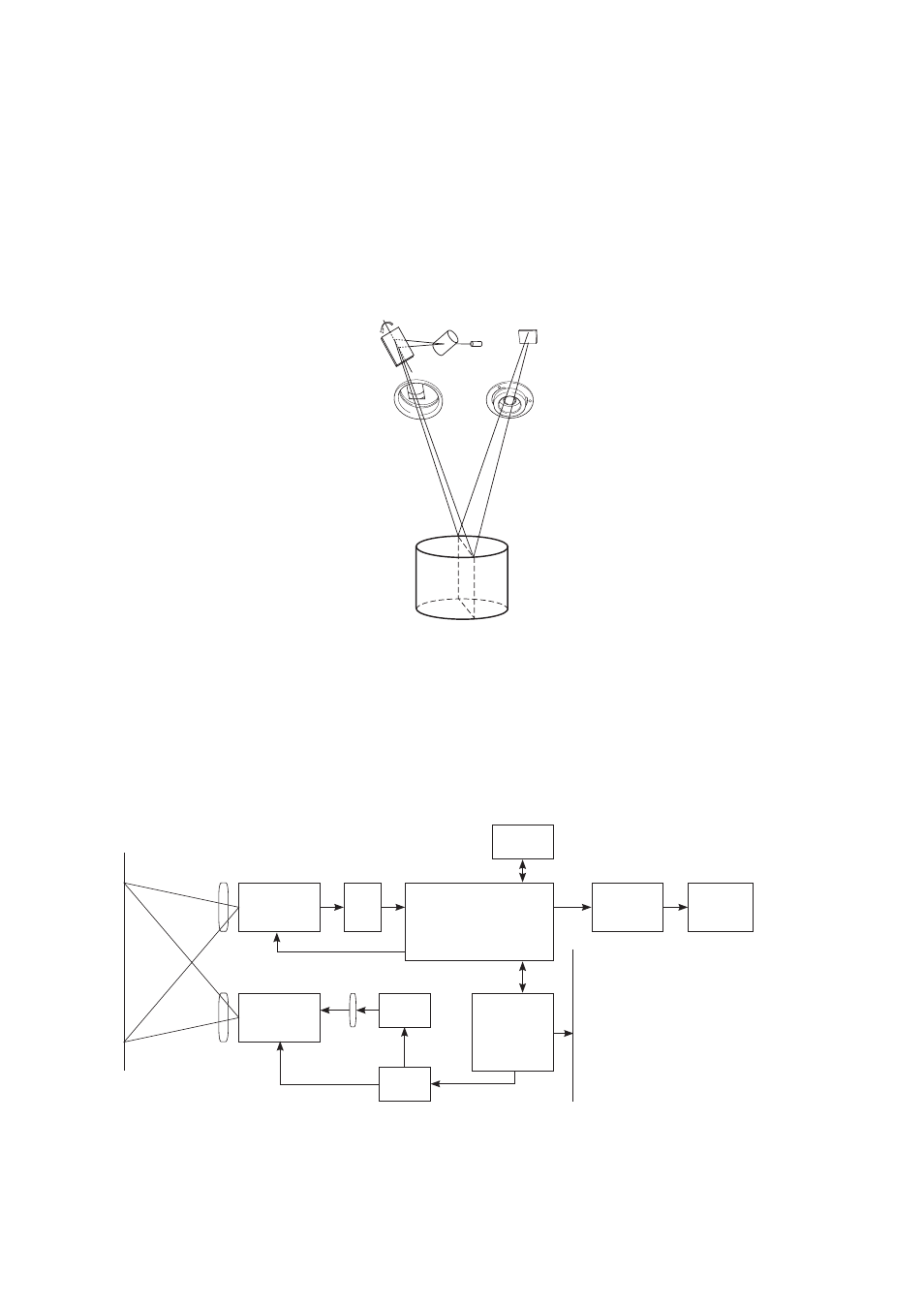

The RANGE7/5 uses the light sectioning method to emit a horizontal stripe light through a cylindrical lens to the object.

The reflected light from the object is received by the CMOS sensor, and then converted by triangulation into distance

information.This process is repeated by scanning the stripe light vertically on the object surface using a Galvano mirror, to

obtain a 3D image data of the object.

The stripe light is scanned on the CMOS image plane at one horizontal line per frame, and the CMOS is driven so that the

block readout start position is shifted one line per frame. Approximately 1400 frames are acquired.

• Frame rate: 600 frames/sec.

• Block readout: 350 lines

The output signal from the CMOS sensor is then converted into a digital signal, which is then subjected to digital signal

processing. The processed data is finally transferred to the computer via the USB interface.

CMOS Sensor

Galvano

Scanner

Lazer

Diodo

CPU

Driver

CPU Data Bus

A/D

FPGA

Frame

Memory

USB Driver

USB

With this instrument, 3D images are obtained by calculating the time center of gravity of each pixel of the CMOS sensor. With

this method, compared to the space center of gravity, use of the time center of gravity reduces the influence of sensitivity

variations of the CMOS sensor pixels and variations in object brightness.

Frame interline

Transfer CCD

Galvano

Scanner

CPU

A/D

Clock Generator

FIFO

Host I/F

DSP

Frame

Memory

Laser

Diode

Driver

CPU Data Bus

Galvano mirror

Emitting lens

Laser beam

Light-receiving lens

Object

CMOS sensor