Chapter 2 - installation – Stellar Industries TELESCOPIC CRANE EC2000 User Manual

Page 7

3

Installation 3

Chapter 2 - Installation

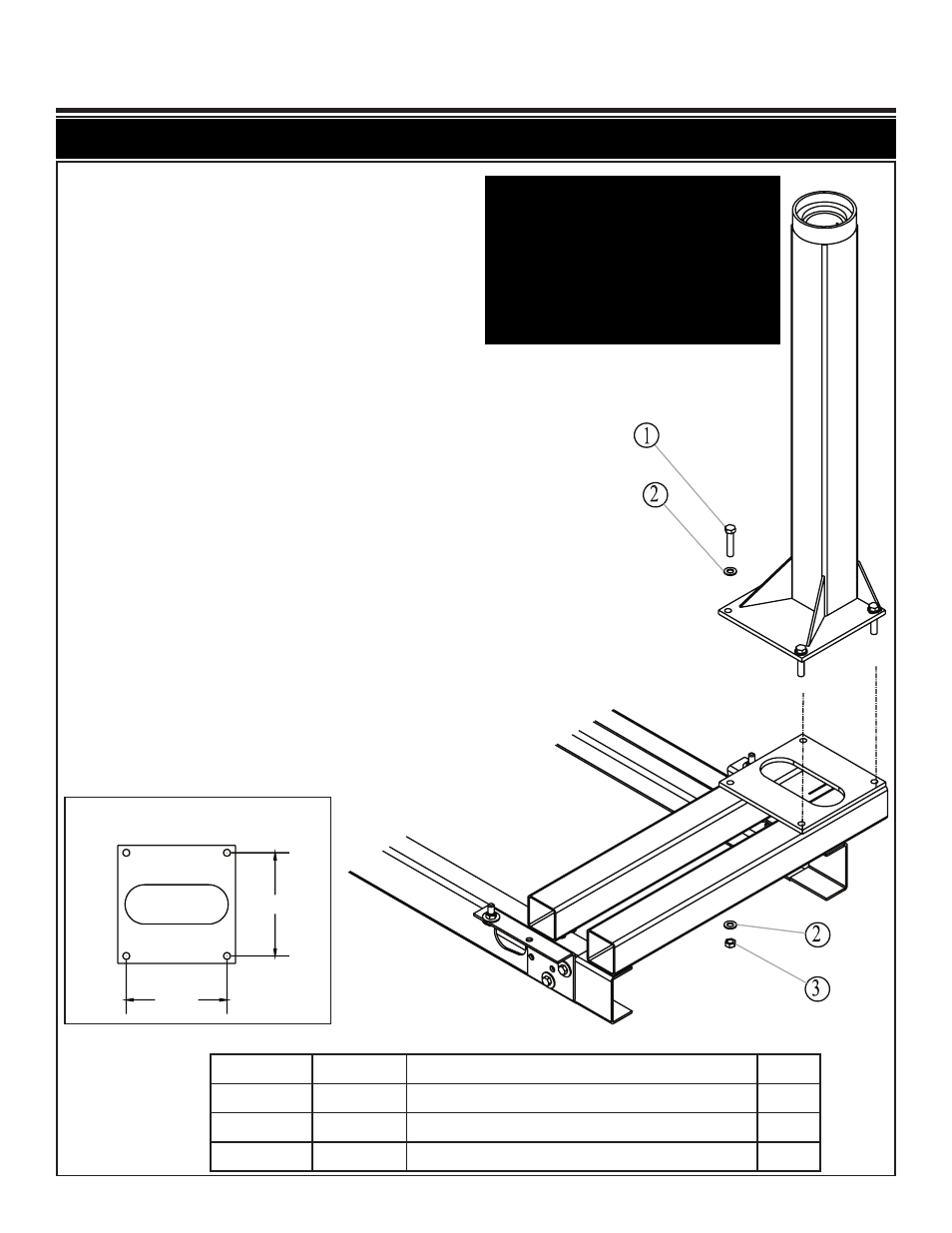

Mounting Hole Diagram

Item No. Part No. Description

Qty.

1

D1034 CAP SCR 0.63-11 X 3.00 HHGR8 ZY

4

2

C5902 WASHER 0.63 FLAT GR8

8

3

2826

NUT 0.63-11 HH NYLOC

4

10.25

10.25

Notice: Read this Page Before Installation of the Crane

Installation Instructions:

Prepare Platform For Crane Installation (Not

Supplied)

1. When designing the platform, maintain a

proper clearance for the crane mount-

ing and operation.

2. The platform must be strong enough to

support the crane and rated load.

3. Platform/crane support minimum require-

ments: Top plate should be made from

0.50” grade 50 plate. The structure

should be supported by 4 x 4 x 3/16 tub-

ing.

Mounting Instructions:

1. Lower the crane onto the mounting plat-

form.

2. Mount the crane using 5/8” grade 8

bolts, flat washers, and nyloc nuts.

3. Connect power (+12V) and ground wires

per winch manufacturer’s specifications.

Power Rotation: Route 4 ga. wires (not

included) from junction box to power

(+12V) and ground. Recommended:

Use solenoid and a toggle switch to

power the crane.

4. Operate the crane for several cycles.

Important: When installing welder units to

the service bodies, it is highly

recommended that a surge protector is

installed on the chassis batteries to protect

the crane radio receiver, wiring and other

electronic devices from an unexpected

electrical spike or surge. Failure to do so

could result in extensive damage to the

service body and crane electrical circuit.