Description of controls & components – Southbend METAL-CUTTING BANDSAW SB1019 User Manual

Page 22

-20-

For Machines Mfg. Since 8/09

Model SB1019

O P E R A T I O N

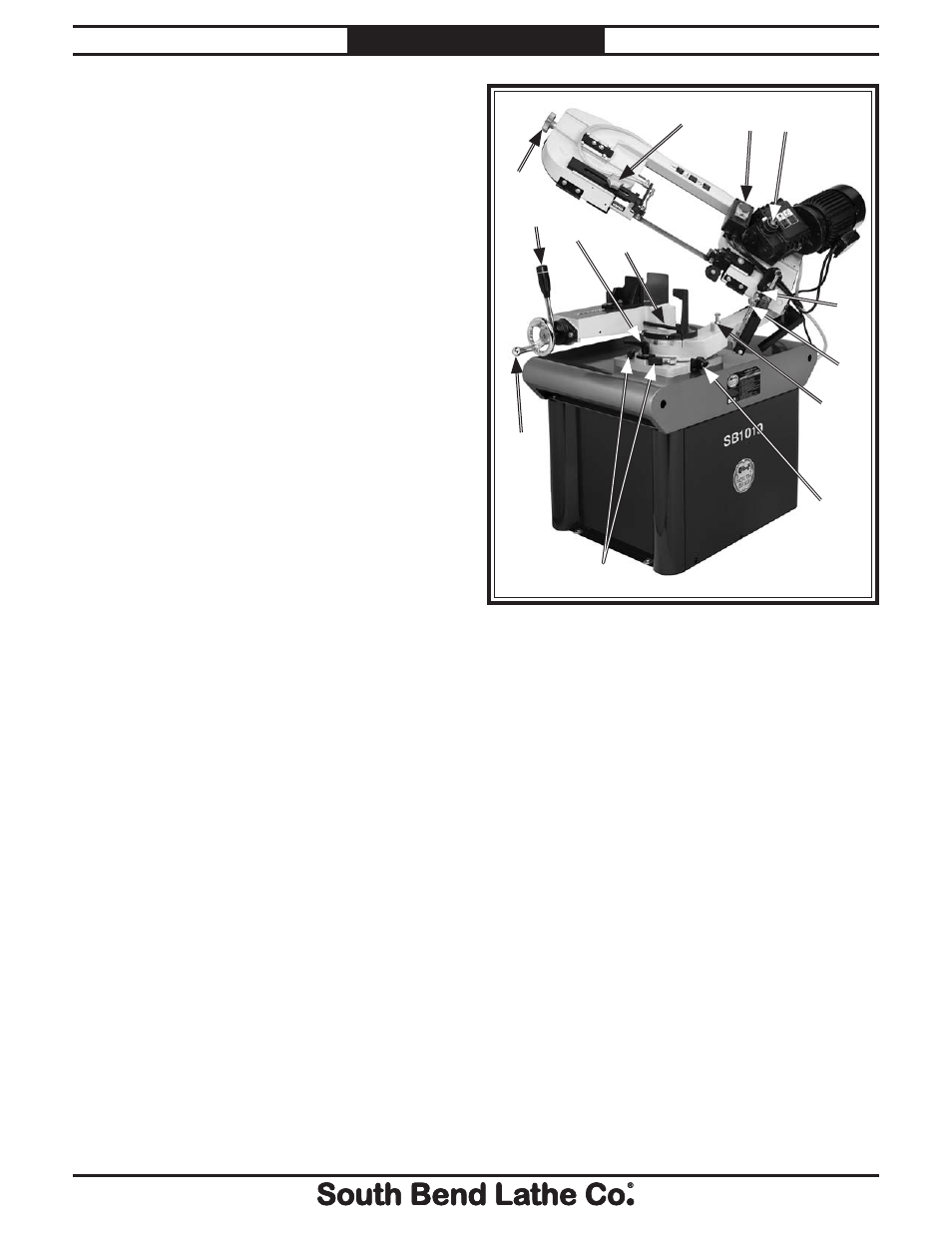

Description of Controls

& Components

Refer to Figure 14 and the following

descriptions to become familiar with the basic

controls and components used to operate this

machine.

A. Blade Tension Knob: Adjusts the position of

the upper blade wheel to apply or release

blade tension.

B. Guide Post Knob: Locks the guide post in the

position set by the operator.

C. ON/OFF Switch: Turns the saw motor ON &

OFF.

D. Speed Selector: Selects one of three blade

speeds.

E. Downfeed Rate Adjust Knob: Controls the

speed at which the blade lowers into the

workpiece.

F. Downfeed Valve: Controls the starting and

stopping of the headstock downfeed.

G. Downfeed Stop Bolt: Adjusts to determine

the absolute bottom limit of blade travel.

H. Headstock 0° Flip Stop: Provides an optional

stop for square cuts.

I. Headstock 45° Stops: Provide stops at 45° to

the left and right for angle cuts.

J. Vise Jaw Handwheel: Controls the vise jaw

movement.

K. Vise Jaw Quick Release Lever: Quickly

opens and closes the vise jaw approximately

1

⁄

16

" for repetitive repositioning/clamping in a

production setting.

L. Headstock Lock Lever: Locks the headstock

at the position set by the operator.

M. Work Stop: Provides an adjustable stop for

cutting multiple workpieces at the same

length.

A

H

I

J

K

L

M

G

F

B

C

D

E

Figure 14. Controls and components.