Sinclair Super Stripper User Manual

Page 5

Changing the driving wheels

Remove the lynch-pins and pull the wheels from the axle. Do not loose the wheel

key under any circumstances.

5.0 Use

The Super

® Stripper removes bonded, flexible floor covering in strips. This

procedure corresponds with the customary method of using a hand floor scraper. The

stripper works with a steel blade at a very high frequency, minimizing vibration and

noise.

The

Super

® Stripper is self propelled. The motor actuates both the blade and the

machine movement. The blade drive starts as soon as the machine is switched on.

Starting

The Super

® Stripper is equipped with an operating switch located at the top of the

handle.

This is a safety switch, which must be held down to engage the

Super

® Stripper. There is a current limiting protective device which causes a two

second delay to full power on start.

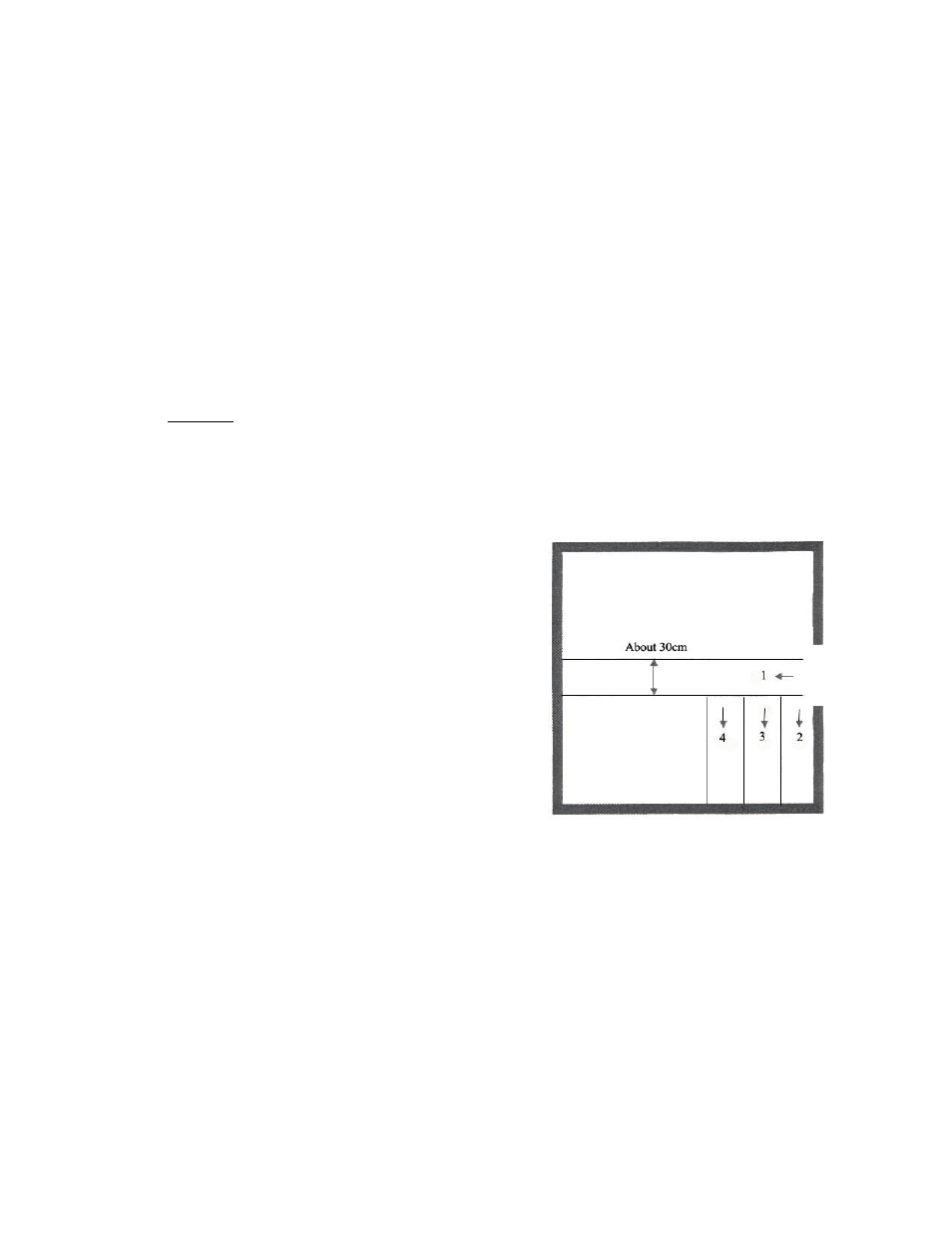

Before starting work, cut the floor covering

into strips of about 30cm (11 inches).

You cannot work faster if you cut wider strips.

To begin, cut one strip crosswise. Then lift the

flooring slightly in order to get the blade

underneath it. We recommend to cut the

first strip at right angles to the main working

direction. By doing so, access to the adjacent

strips is made easier. Cut the strips smaller if

the floor covering is bonded very securely, e.g.

with an epoxy adhesive.

The blades are sharpened by the floor pavement. Therefore the blade has to be

changed only if it is twisted or becomes worn.

The driving wheels are subject to wear. They have to be changed after approximately

16mm (0.6 inch) of the surface has been worn away. Otherwise the working angle of the

striking apparatus will not be correct especially critical with cork or foam backed carpets.

5