Belt tension safety switch, Belt tracking safety switch – Woodstock SHOP FOX W1737 User Manual

Page 34

-32-

W1737/W1738 Owner's Manual (Mfg. 10/09+)

SE

RV

IC

E

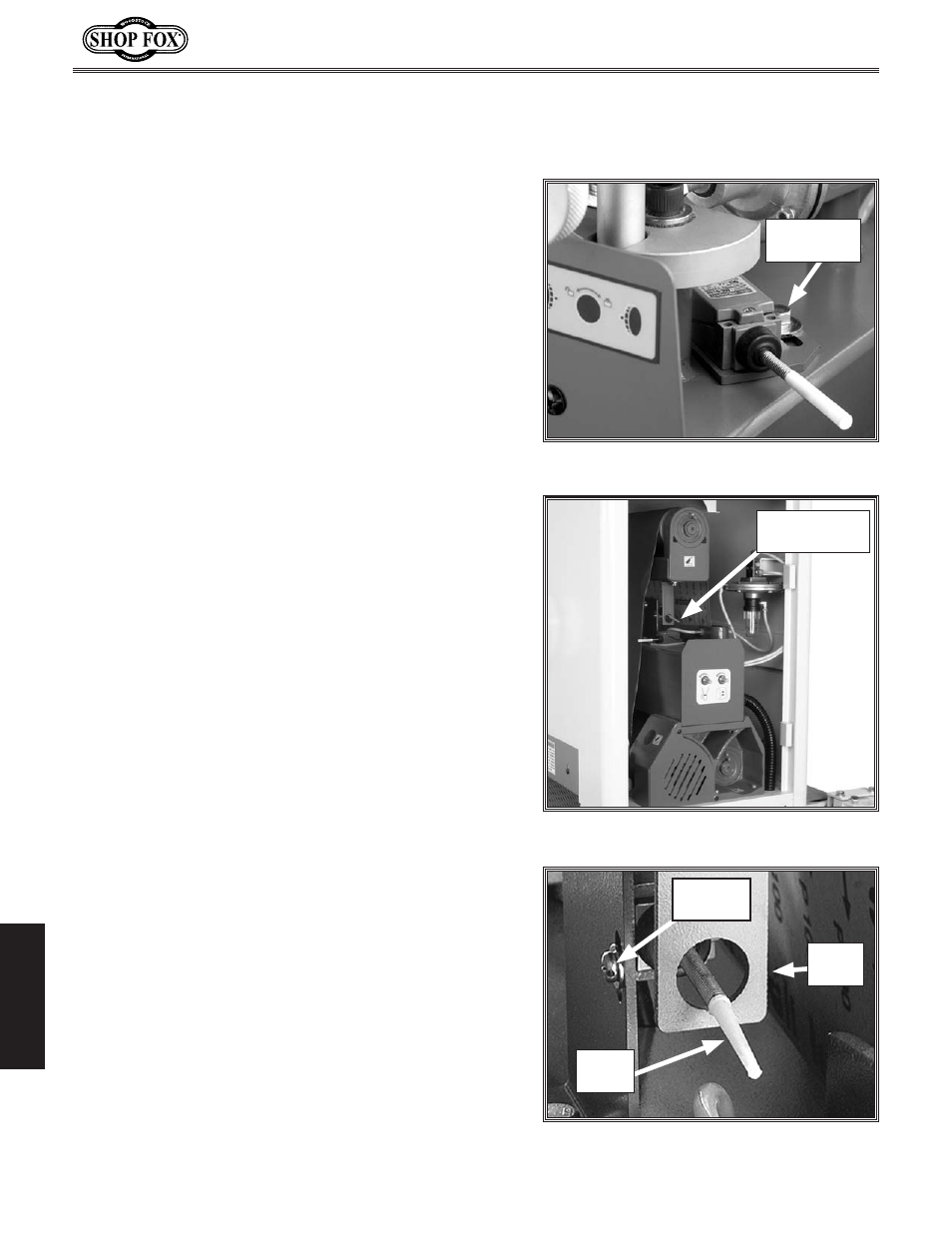

Figure 48. Tracking safety switch

adjustment bolt.

Belt tracking safety switches are placed on both sides of

the belt to act as emergency machine stops if the belt

travels too far to one side during oscillation. See

Figure

48.

To adjust the belt tracking safety switches, do these

steps:

1. TURN OFF and LOCK the master power switch so

that no power can go to your sander!

2. Make sure the belt tracking and oscillation is

adjusted.

3. Release the belt tension, center the sanding belt on

the top roller, then re-tension the belt.

4. Measure the distance from the edge of the sanding

belt to the ceramic rod protruding from the switch.

5. Loosen the adjustment bolt shown in Figure 48, and

move the switch so the belt and the ceramic rod have

approximately

1

⁄

2

" clearance from each other.

6. Tighten the bolt and repeat the adjustment with the

other side if necessary.

7. Start the sander and make sure it is working

properly.

Adjustment

Bolt

Figure 49. Belt tension safety switch

location.

Belt Tension Safety

Switch

The belt tension safety switch shuts the sanding motor

OFF

if the belt breaks or has no tension when the lock

flange pushes the belt tension safety switch lever. See

Figures 49 and 50.

To adjust the belt tension safety switch, do these

steps:

1. TURN OFF and LOCK your master power switch.

2. Apply normal system air pressure of 70 PSI, and

tension the belt.

3. Loosen the mounting screw and position the switch

so the lever is in the center of the lock flange hole.

4. Re-tighten the screw and test the switch operation.

Belt Tension

Safety Switch

Figure 50. Belt Tension safety switch.

Lock

Flange

Switch

Lever

Mounting

Screw

Belt Tracking Safety

Switch