Air hose installation, Sanding belt installation, Notice – Woodstock SHOP FOX W1737 User Manual

Page 16

-14-

W1737/W1738 Owner's Manual (Mfg. 10/09+)

SE

TU

P

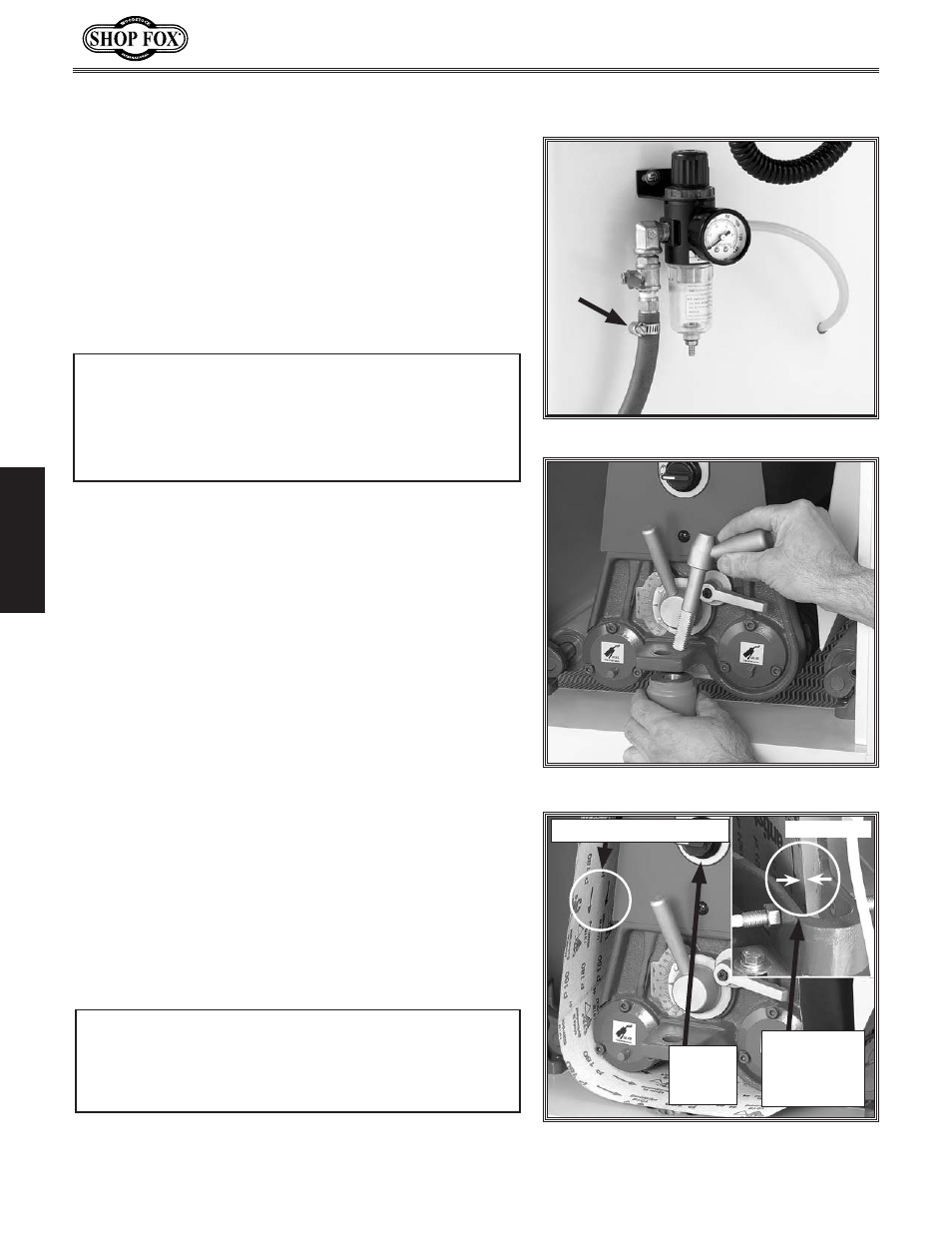

Air Hose Installation

Push your air supply hose onto the air pressure regulator

inlet fitting, and clamp it in place with a hose clamp as

shown in

Figure 10. If you prefer, you can replace the

included air nozzle with a

3

⁄

8

" male quick connect air

coupling.

When the air hose is installed, pull up and rotate the

regulator air pressure knob until the gauge reads 70 PSI

then push down. DO NOT attempt to regulate the air

pressure with the ON/OFF air supply lever. This lever is

the ON/OFF air pressure to the machine only.

Sanding Belt Installation

Before installing belt, clean the protective grease from

the upper metal sanding belt roller as per the

Cleaning

Machine instructions on Page 13.

To install the sanding belt, do these steps:

1. TURN OFF and LOCK your master power switch, but

keep the air pressure going into the machine.

2. Turn and remove the lever and support spacer as

shown in

Figure 11.

3. Install the sanding belt so the belt is centered in

the fork (see

Figure 12a), and the belt arrows are

pointing in the direction of drum rotation (see

Figure

12).

4. Center the belt on the rollers.

5. Reinstall the support spacer and lever.

6. Turn the belt tension knob to the 12:00 position and

the belt will automatically tighten to the correct

tension. At the 9:00 position the belt will have no

tension.

Figure 10. Air hose attached to regulator.

Figure 11. Lever removal/installation.

Figure 12. Installing sanding belt left and

right machine view.

Belt

Tension

Knob

TENSION the sanding belt before starting the sander,

and DE-TENSION the belt when sander is not in use, or

you will damage the belt.

NOTICE

Correct Belt Direction

To achieve maximum life of the air system o-rings,

gaskets, and components, keep the air pressure shut

off when not using the sander, and DO NOT exceed

75 PSI.

NOTICE

Make Sure

the Belt is

Centered

In the Fork

Figure 12a