Brake service – Woodstock SHOP FOX W1737 User Manual

Page 29

-27-

W1737/W1738 Owner's Manual (Mfg. 10/09+)

SE

RV

IC

E

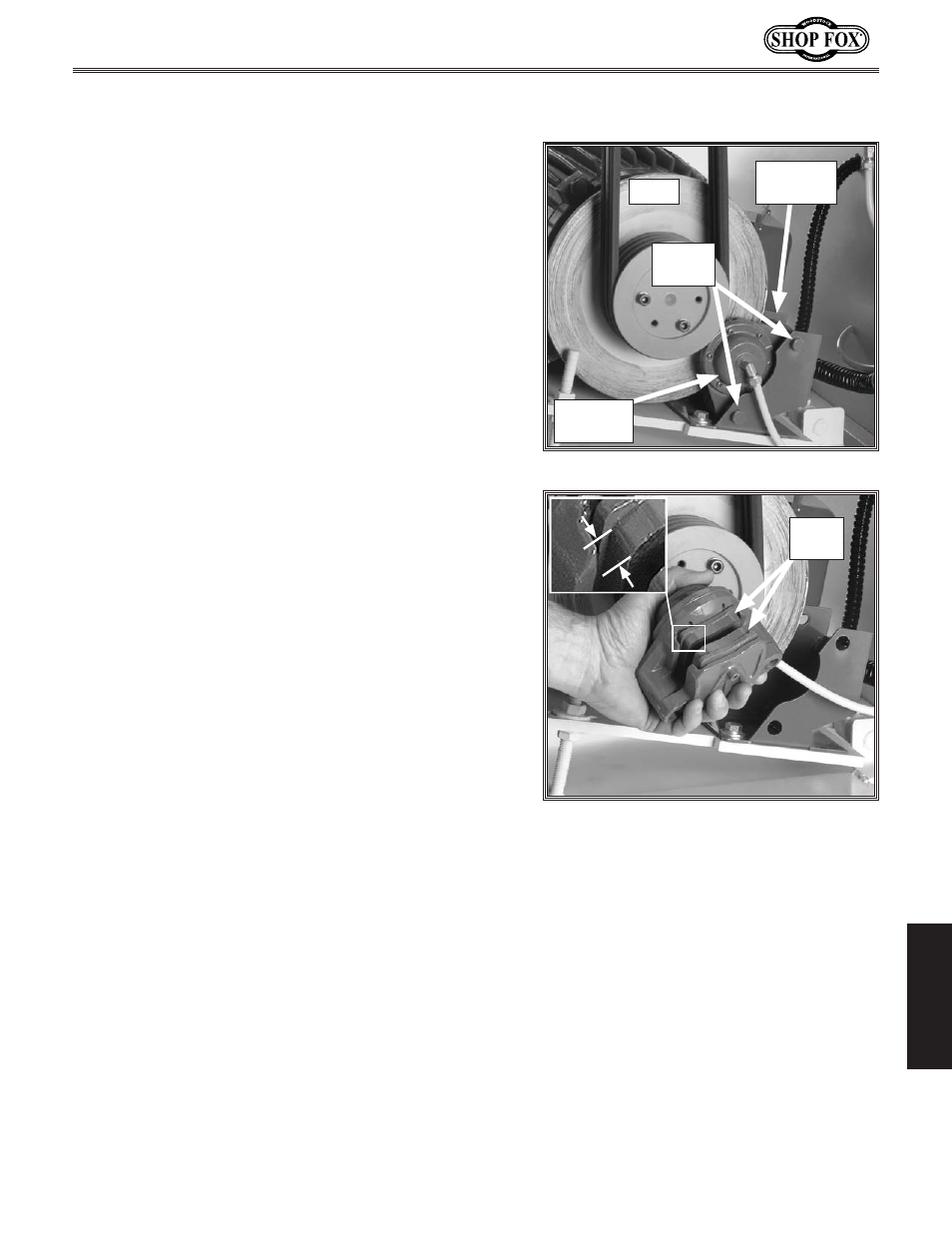

Figure 36. Brake assembly.

Figure 37. Brake caliper removed for

access to brake pads.

Brake Service

Check the brake rotor (shown in

Figure 36) regularly

to make sure it is clean and the pads are still in good

condition (thicker than

1

⁄

8

", see

Figure 37). Using the

emergency stop system for daily machine shutdown will

wear out the sanding belts and the brake pads. Inspect

for any grease or oil on the brake rotor as oil reduces

emergency braking ability. To clean any lubricants from

the rotor, only use automotive brake parts cleaner and

a dry rag. Replace brake shoes if they are contaminated

with oil. DO NOT re-use!

To check the condition of the brake pads, do these

steps:

1. TURN OFF and LOCK the master power switch so

no power can go to your sander, and shut OFF and

relieve the air pressure!

2. Remove the lower-right motor-access panel.

3. Measure the thickness of each pad. If a pad is below

1

⁄

8

", then replace both.

To replace the brake pads, do these steps:

1. TURN OFF and LOCK the master power switch so

no power can go to your sander, and shut OFF and

relieve the air pressure!

2. Use a 14mm wrench and remove the two caliper

anchor pin retaining nuts and washer (see

Figure

36).

3. Use locking pliers to clamp on the anchor pin

end and pull the pin from the caliper mount, and

remove the springs and caliper (see

Figure 37).

4. If the rotor is damaged, remove the rotor and have

it surfaced at a machine shop. Clean the rotor with

automotive brake parts cleaner and handle it with a

dry rag when installing.

5. To finish the job, install the new brake pads,

reassemble and mount the caliper, and reconnect

the air line if removed.

6. Test the emergency brake operation!

Retaining

Nut

Rotor

Caliper

Assembly

Anchor

Pins

Brake

Pads

1

⁄

8

"

Min