P231 specifications, Sharpening the chain – Shindaiwa 63888-94010 User Manual

Page 9

P231 Specifications

Dry Weight ................... 6.1 kg/

13.4 lb.

Length w/10" bar

assembly .......... 2804 mm/

110.4 in.

Engine Type ............ 2-cycle, air-cooled,

vertical-cylinder

Bore x Stroke ... 32 x 28 mm/

1.3 x 1.1 in.

Displacement ......... 22.5 cc/

1.4 cu. in.

Maximum Output .......... 0.8kW/

1.1 hp

@ 7500 rpm (min

-1

)

Fuel/oil ratio ...... 50:1 with ISO-L-EGD

or JASO FC class 2-cycle Mixing Oil

Shindaiwa ONE is a registered

JASO FC classified oil and also meets

or exceeds ISO-L-EGD performance

requirements.

Fuel Tank Capacity .... 670 ml/

22.7 oz.

Carburetor Type ....... Walbro WYL-122

Ignition .............. One-piece, electronic,

transistor-controlled

Spark Plug ..................... Champion CJ8

Air Filter .......... Non-reversible flocked

filter element

Muffler Type ............... 2-Stage Catalyst

Starting Method .......................... Recoil

Cooling System ..................... Forced air

Stopping Method ............... Slide switch

Specifications are subject to change without notice.

Transmission Type .............. Automatic,

centrifugal clutch with bevel gear

Chain Guide Bar ................. 3/8" pitch,

.043" gauge, 10-inch Micro Lite™

Chain Type ..... 3/8" pitch Micro Lite™,

.043" gauge

Sprockets .............. 3/8-inch, fixed spur

Gearcase Ratio ........................... 1.06 : 1

Chain Speed .......... 23.5 m (

77 ft.

)/sec.

@ 10,000 rpm (min

-1

)

Chain Lubrication ................. Automatic

adjustable oiler

Chain Lubricant ... Shindaiwa Premium

Bar and Chain Oil

Standard Equipment ............ Bar/chain

scabbard, tool kit containing a

spark plug wrench, 4 mm hex

wrench and 8 mm x 10 mm spanner

Optional Equipment .... Shoulder strap,

loop handle

Optional Bars ............. 8-inch or 12-inch

EPA Emission

Compliance Period* ........... Category A

* The EPA emission compliance referred to

on the emission compliance label located on

the engine, indicates the number of operating

hours for which the engine has been shown

to meet Federal emission requirements.

Category C = 50 hours (Moderate), B = 125

hours (Intermediate) and A = 300 hours

(Extended).

9

DESCRIPTION

Sharpening the Chain

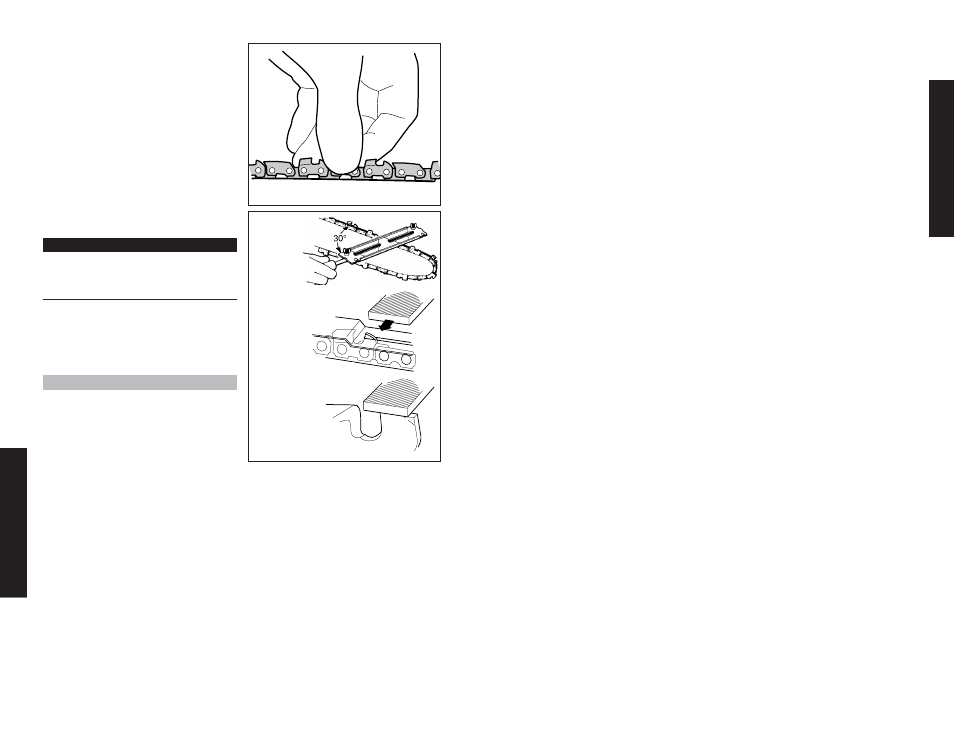

Sharpening Instructions (Fig.37)

Using a depth

gauge joiner

Using a flat

file to round

the front

corner on a

depth gauge

When the cutting edges of the

blade become dull, they can be re-

sharpened with a few strokes of a file.

In order to keep the blade in

balance, all cutting edges must be

sharpened equally.

In addition, inspect the chain for

correct adjustment (more frequently

with a new chain). The chain should

feel snug but still pull freely. See

Figure 36. Refer to page 16 for

adjustment procedures.

P231_41

Figure 36

Figure 37

P231_44

P231_43

P231_42

Using a filing

gauge

28

IMPORTANT!

File all cutters to the same angle and

depth! Unequal filing may cause the

saw to vibrate or cut erratically!

NOTE:

For consistent filing angles, use a

filing guide such as Oregon

ா

p/n

31692 or equivalent.

1. Using a 4.5 mm round file, sharpen

all cutters to a 30

°

angle. Make

sure that one fifth (20%) of the file’s

diameter is always held above the

cutter’s top plate.

2. After all cutters are sharpened, use

a depth gauge joiner (Oregon

ா

p/n 106738 or equivalent) to

measure the height of each depth

gauge.

3. As required, lower the depth

gauges to a height of 0.020 inch.

Use a flat file; (Oregon

ா p/n 12211

or equivalent).

4. After all depth gauges have been

adjusted, use a flat file to round

each depth gauge leading edge to

its original curvature and angle.

MAINTENANCE