Daily maintenance – Shindaiwa 63888-94010 User Manual

Page 14

P231_13

P231_12

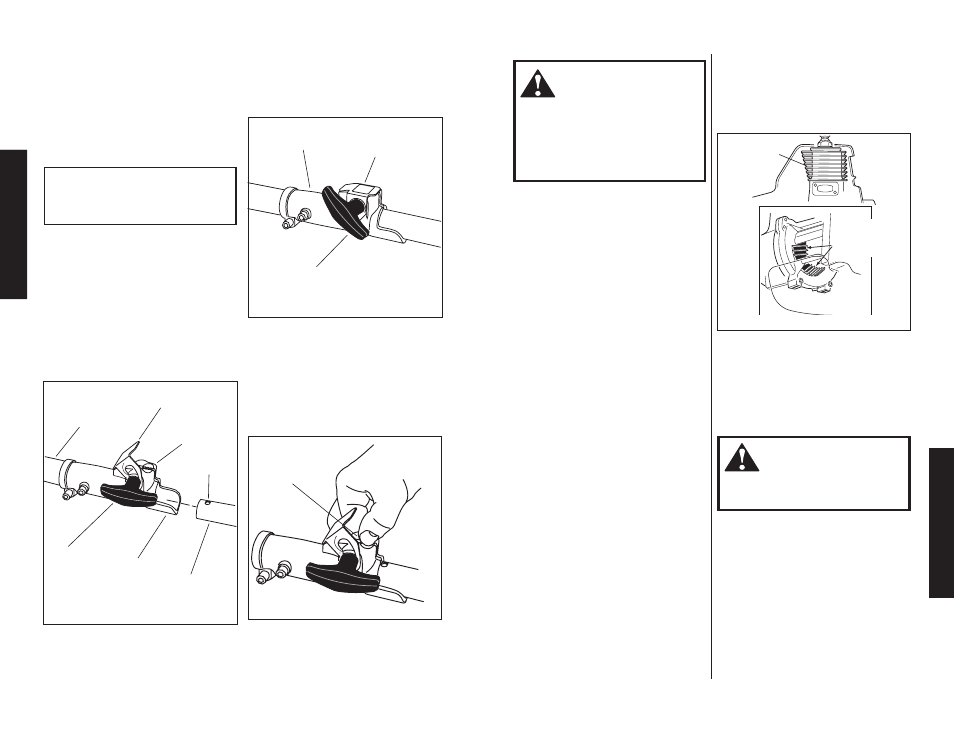

Assembling the Tube Sections

Figure 11

Tube

Assembly

Disassembling The Pole Sections

1. With the pole pruner on a clean, flat

surface, loosen the coupler screw.

The spring-loaded coupler protec-

tor should pop up.

2. Press down on the latch with your

finger or thumb. See Figure 13.

This releases the coupler lock.

Tube

Assembly

Coupler

Latch

Coupler

Screw

Knob

Locking

Hole

Latch Protector

(extended)

Latch Protector

(lowered)

Coupler Screw

Knob

Coupler

Figure 12

Figure 13

Press

Latch

P231_14

14

1. Place the powerhead/lower tube

assembly and the upper tube

assembly on a clean, flat surface so

that both assemblies fit end to end.

The powerhead/lower tube

assembly should be facing up, and

the lower tube assembly should be

positioned with the locking hole in

the tube end facing up.

CAUTION!

Keep the open ends of the tubes

clean and free of debris!

3. Pull the upper tube assembly out of

the coupler.

2. Slip off the protective covers from

the ends of both tubes, and loosen

the coupler screw knob.

3. Insert the upper tube assembly into

the coupler, arrow on the upper

tube decal facing up, until the line

of the decal is flush with the end of

the coupler. Rock the upper tube

back and forth until you are sure

the latch snaps in place by the

coupler lock. See Figure 11.

4. When the two tube halves are

locked together, press down on the

spring-loaded latch protector and

tighten the coupler screw. See

Figure 12.

ASSEMBLY

Prior to each work day, perform the

following:

■ Remove all dirt and debris from the

engine, check the cooling fins and

air cleaner for clogging, and clean

as necessary. See Figure 29.

Daily Maintenance

■ Carefully remove any accumulations

of dirt or debris from the muffler and

fuel tank. Check cooling air intake

area at base of crankcase. Remove

all debris. Dirt build-up in these areas

can lead to engine overheating, fire,

or premature wear.

WARNING!

Operating the engine without a

muffler or with a muffler that is

damaged or improperly installed

can increase engine noise suffi-

ciently to cause hearing loss.

P231_33

Figure 29

Keep cooling

fins clean

Keep air

passages

clean

23

Muffler

This unit must never be operated with a

faulty or missing spark arrestor or

muffler. Make sure the muffler is well

secured and in good condition. A worn

or damaged muffler is a fire hazard and

may also cause hearing loss.

Spark Plug

Keep the spark plug and wire connec-

tions tight and clean.

WARNING!

Always wear gloves when working

around the cutter assembly.

■ Clean any debris or dirt from the

cutting attachment. Check the bar

and chain for damage or incorrect

adjustment.

■ Check for loose or missing screws or

components. Make sure the cutter

attachment is securely fastened.

■ Check the entire unit for leaking

fuel or grease.

■ Make sure nuts, bolts, and screws

(except carburetor idle speed

adjusting screws) are tight.

MAINTENANCE