Troubleshooting, Se rv ic e – Woodstock SHOP FOX M1014 User Manual

Page 37

-35-

M1014 7" x 12" Metal Cutting Bandsaw

SE

RV

IC

E

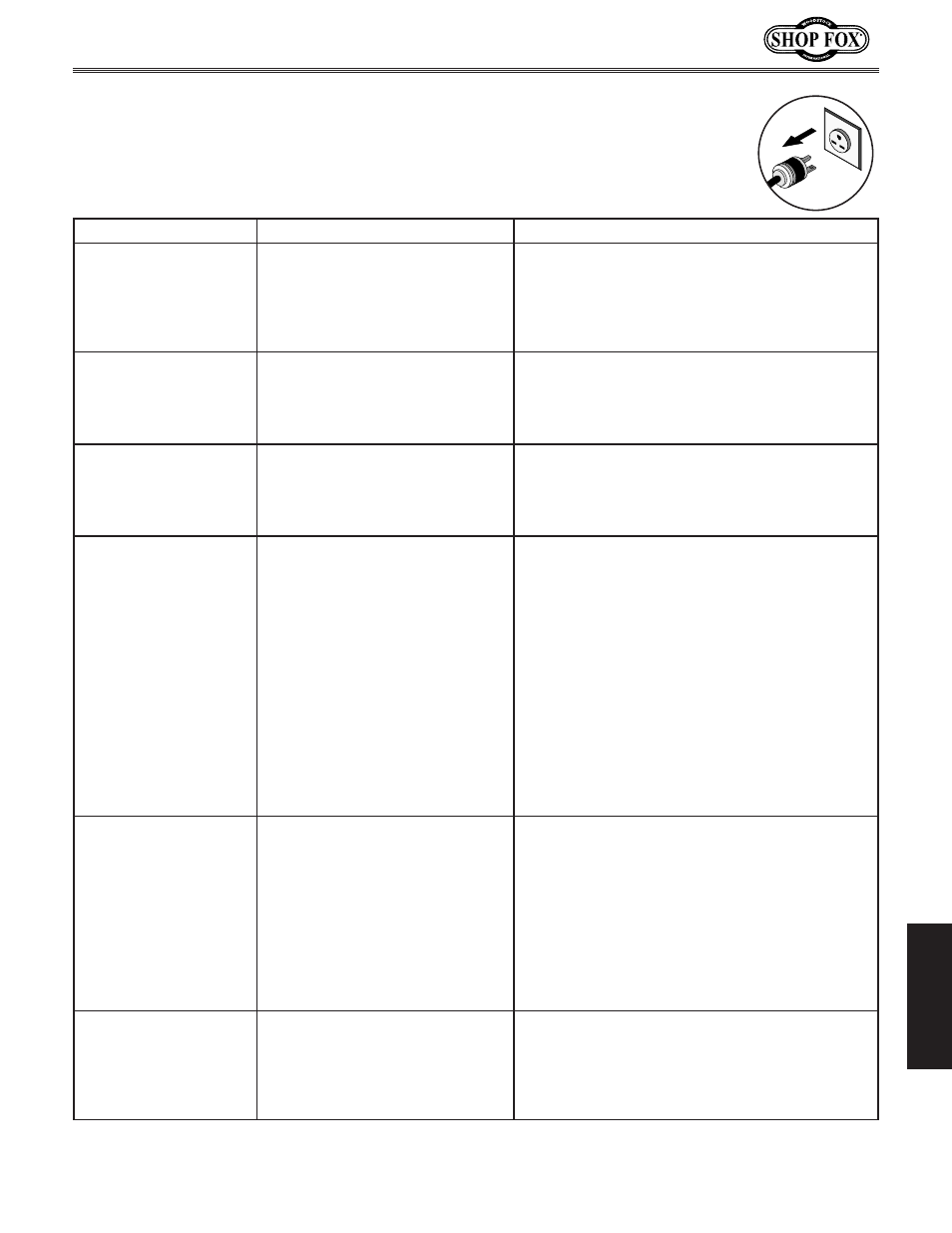

SYMPTOM

POSSIBLE CAUSE

CORRECTIVE ACTION

Motor will not start.

1. Low or no voltage.

2. Faulty start capacitor.

3. Motor is at fault.

1. Open or short circuit in line cord or plug resulting

in blown fuse or tripped breaker. Repair for cause

of short or open circuit.

2. Replace start capacitor.

3. Motor has shorted or open windings. Replace

motor.

Motor automatically shuts

off (possibly resulting in

blown fuse or tripped

circuit breaker or in power

supply circuit).

1. Faulty start capacitor.

2. Bandsaw is jammed.

3. Short circuit in motor or loose

connections.

1. Replace start capacitor.

2. Remove part or metal that is binding bandsaw.

3. Refer to

Wiring Diagrams on Pages 33 and 34, and

inspect connections on motor for loose or shorted

terminals or worn insulation and repair.

Machine is loud when

cutting or bogs down in

the cut.

1. Excessive feed rate.

2. The blade TPI is too great, or the

material is too coarse.

3. The run capacitor is at fault.

1. Refer to Feed Rate on Page 27, or Changing

Cutting Speed on Page 19, and adjust as required.

2. Refer to Blade Selection on Page 24 and adjust as

required.

3. Replace the run capacitor.

Blades break often.

1. The workpiece is loose in the vise.

2. The feed or cut speed is wrong.

3. The blade TPI is too great, or the

material is too coarse.

4. The blade is rubbing on the wheel

flange.

5. The bandsaw is being started

with the blade resting on the

workpiece.

6. The guide bearings are misaligned,

or the blade is rubbing on the

wheel flange.

7. The blade is too thick, or the

blades are of low quality.

1. Clamp the workpiece tighter, or use a jig to hold

the workpiece.

2. Refer to Feed Rate on Page 27, or Changing

Cutting Speed on Page 19, and adjust as required.

3. Refer to Blade Selection on Page 24, and adjust

as required.

4. Refer to Blade Tracking on Page 31, and adjust as

required.

5. Start bandsaw and then slowly lower the headstock

by setting the feed rate.

6. Refer to Blade Tracking on Page 31, or

Blade

Guides on Page 21, and adjust as required.

7. Use a higher quality blade.

Blade dulls prematurely.

1. The cut speed is too fast.

2. The blade TPI is too coarse.

3. The blade feed pressure is to light.

4. The workpiece has hard spots,

welds, or scale is on the material.

5. The blade is twisted.

6. The blade is sipping on the

wheels.

1. Refer to Changing Cutting Speed on Page 19,

and adjust as required.

2. Refer to Blade Selection on Page 24, and adjust

as required.

3. Refer to Feed Rate on Page 27, and adjust as

required.

4. Increase the feed pressure, and reduce the cutting

speed.

5. Replace the blade.

6. Refer to

Blade Tension on Page 20, and adjust as

required.

Blade wears on one side.

1. The blade guides are worn or mis-

adjusted.

2. The blade guide slide bracket is

loose.

3. The wheels are out of alignment.

1. Refer to

Blade Guides on Page 21 and replace or

adjust.

2. Tighten the blade guide bracket.

3. Refer to

Blade Tracking on Page 31, and adjust as

required.

Troubleshooting

This section covers the most common symptoms and corrections with this type of

machine.

WARNING! DO NOT make any adjustments until power is disconnected and

moving parts have come to a complete stop!