Air purging, Air purging with a vacuum pump (for test run), Ab c d – Sanyo CM1972 User Manual

Page 80

18

4. Air Purging

Air and moisture remaining in the refrigerant

system have undesirable effects as indicated

below. Therefore, they must be purged completely.

●

pressure in the system rises

●

operating current rises

●

cooling efficiency drops

●

moisture in the air may freeze and block

capillary tubing

●

water may lead to corrosion of parts in the

refrigerant system

■

Air Purging with a Vacuum Pump

(for Test Run)

●

In order to protect the earth’s environment, be sure to use

a vacuum pump to perform the air purge.

(Never perform an air purge by using the refrigerant gas

cylinder or other external gas, or by using the gas inside

the outdoor unit.)

Perform the air purge for tubes A, B, C, and D. Use the

same procedures for all tubes.

(1) Check that each tube (both narrow and wide tubes)

between the indoor and outdoor units have been

properly connected and all wiring for the test run has

been completed. Note that both narrow and wide tube

service valves on the outdoor unit are kept closed at

this stage.

(2) Using an adjustable wrench or box wrench, remove

the valve caps from the service valve on both narrow

and wide tubes.

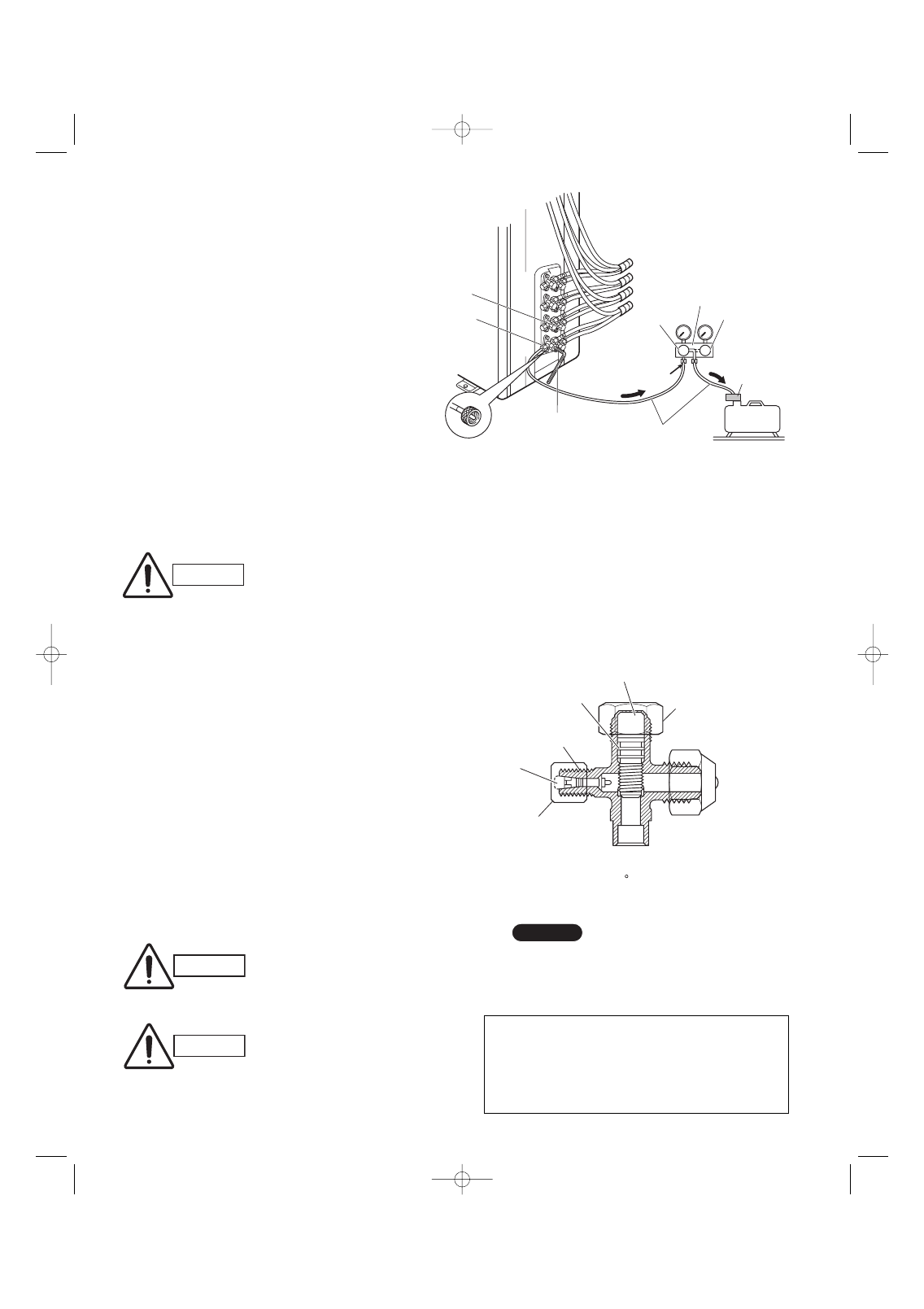

(3) Connect a vacuum pump and a manifold valve (with

pressure gauges) to the service port on the wide tube

service valve. (Fig. 20).

Fig. 20

CAUTION

Be sure to use a manifold valve for

air purging. If it is not available,

use a stop valve for this purpose.

The “Hi” knob of the manifold

valve must always be kept closed.

CAUTION

CAUTION

Before using the vacuum pump

adapter, read the vacuum pump

adapter manual, and use the

adapter correctly.

In order to prevent charging errors with

A/C that uses R410A, the screw diameter

at the service valve charging port has

been changed. When recharging or per-

forming other servicing, use the special

charging hose and manifold gauge.

●

When using a hex wrench to open the spindle, an

extremely small amount of refrigerant may leak.

This does not indicate a problem.

●

Use a hex wrench of a type to which force can be

easily applied.

Service

valve on

wide tube

side

Service

valve on

narrow

A

B

C

D

Vacuum

pump

Vacuum pump

adapter

(for preventing

reverse flow)

(special for

R410A)

High-pressure valve

Manifold gauge

(special for R410A)

Low-pressure

valve

Leave the

valve open.

Open

Charging hose

(special for R410A)

Hex wrench

With push-pin

Hi

Lo

Cap tightening torque:

170 – 215 lbs·in

(200 – 250 kgf·cm)

(Tighten by hand, then

use a wrench to turn.)

Stopper

Spindle

Screw diameter: 1/2

UNF 20 threads

Valve core

Cap nut tightening torque:

60 – 95 lbs·in

(70 – 110 kgf·cm)

(Tighten by hand, then use a

wrench to turn approximately 30 .)

Service port

NOTE

External diameter of service port

R410A: 5/16"

Fig. 21

07-156 CM-CLM1972-3172 6/6/07 9:35 AM Page 18