Adjusting engine idle, Maintenance (continued) long term storage – Shindaiwa Articulated Hedge AHS254 User Manual

Page 21

21

Carburetor Adjustment

Engine Break-In

New engines must be operated a minimum duration of two tanks of fuel break-in before carburetor adjustments can be

made. During the break-in period your engine performance will increase and exhaust emissions will stabilize. Idle speed can

be adjusted as required.

High Altitude Operation

This engine has been factory adjusted to maintain satisfactory starting, emission, and durability performance up to

1,100 feet above sea level (ASL) (96.0 kPa). To maintain proper engine operation and emission compliance above

1,100 feet ASL the carburetor may need to be adjusted by an authorized Shindaiwa service dealer.

nOTE:

Every unit is run at the factory and the carburetor is set in compliance with emis-

sion regulations. Carburetor adjustments, other than idle speed, must be per-

formed by an authorized Shindaiwa dealer.

IMPORTAnT!

If the engine is adjusted for operation above 1,100 feet ASL, the carburetor

must be re-adjusted when operating the engine below 1,100 feet ASL, other-

wise severe

engine damage may result.

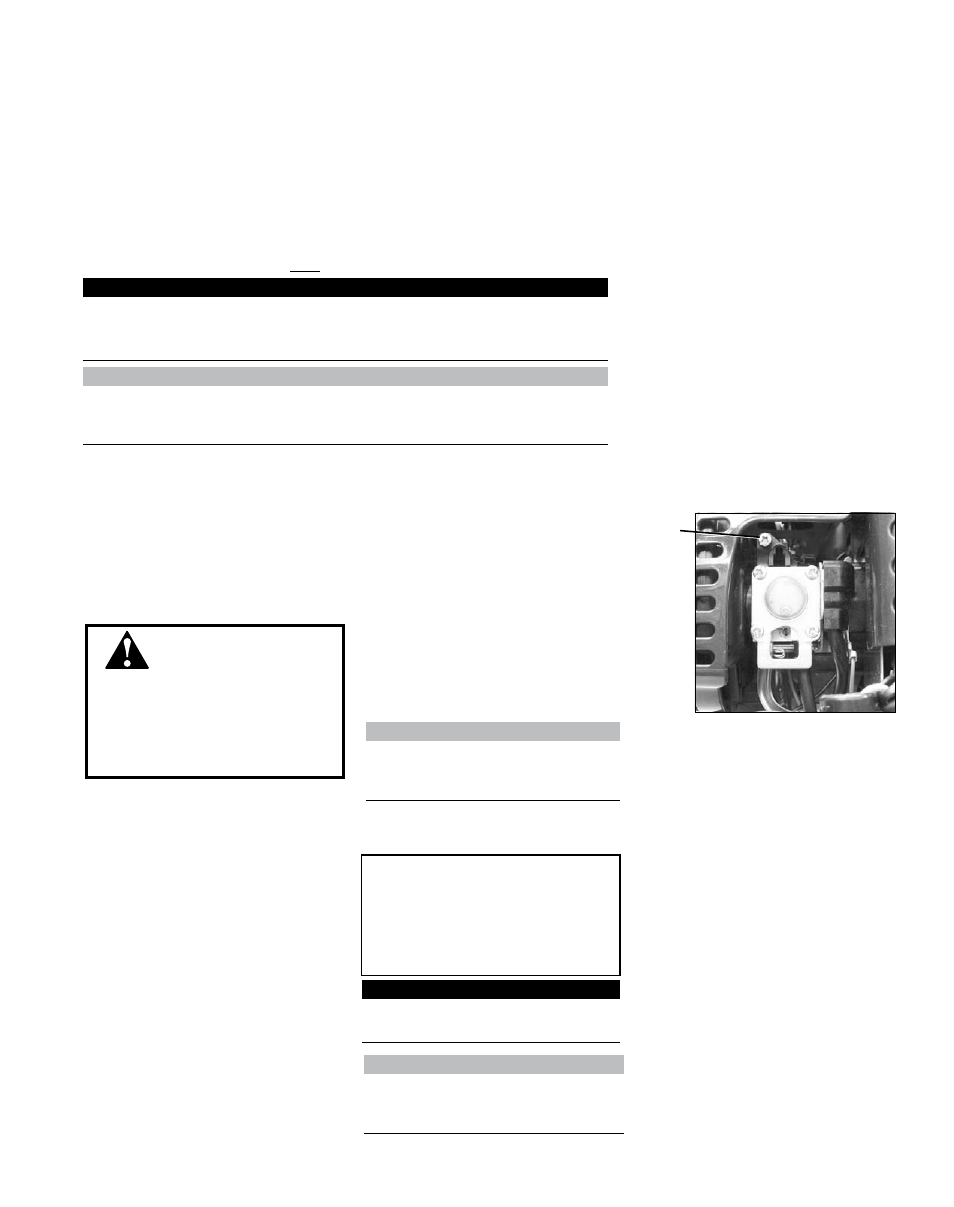

Adjusting Engine Idle

The engine must return to idle speed

whenever the throttle trigger is

released. Idle speed is adjustable, and

must be set low enough to permit the

engine clutch to disengage the cutting

attachment.

wARnInG!

The cutting attachment

must NEVER move at engine idle! If

the idle speed cannot be adjusted by

the procedure described here, return

the unit to your Shindaiwa dealer for

inspection.

Idle Speed Adjustment

1. Place the unit on the ground, then

start the engine, and then allow it to

idle 2-3 minutes until warm.

2. If the attachment moves when the

engine is at idle, reduce the idle

speed by turning the idle adjustment

screw counter-clockwise.

3. If a tachometer is available, adjust

idle. Check Specifications page for

correct idle speed

nOTE:

Carburetor fuel mixture adjustments

are preset at factory and cannot be

serviced in the field.

Maintenance (continued)

Long Term Storage

Whenever the unit will not be used for

30 days or longer, use the following pro-

cedures to prepare it for storage:

■

Clean external parts thoroughly and

apply a light coating of oil to all metal

surfaces.

■

Drain all the fuel from the carburetor

and the fuel tank.

To do so:

1. Prime the primer bulb until no more

fuel is passing through.

2. Start and run the engine until it stops

running.

3. Repeat steps 1 and 2 until the engine

will no longer start.

■

Remove the spark plug and pour

about 1/4 oz. of engine oil into the

cylinder through the spark plug hole.

Slowly pull the recoil starter 2 or 3

times so oil will evenly coat the inte-

rior of the engine. Reinstall the spark

plug.

■

Before storing the unit, repair or

replace any worn or damaged parts.

■

Remove the air cleaner element from

the carburetor and clean it thor-

oughly with soap and water. Let dry

and reassemble the element.

■

Store the unit in a clean, dust-free

area.

CAUTIOn!

Gasoline stored in the carbure-

tor for extended periods can cause

hard starting, and could also lead to

increased service and maintenance

costs.

IMPORTAnT!

All stored fuels should be stabilized with

a fuel stabilizer such as STA-BIL™.

nOTE:

Damage resulting from stale or con-

taminated fuel is not covered by the

Shindaiwa warranty policy.

Idle

Ajust-

ment

Screw