Operation, Maintenance – Shindaiwa 80045 User Manual

Page 7

5

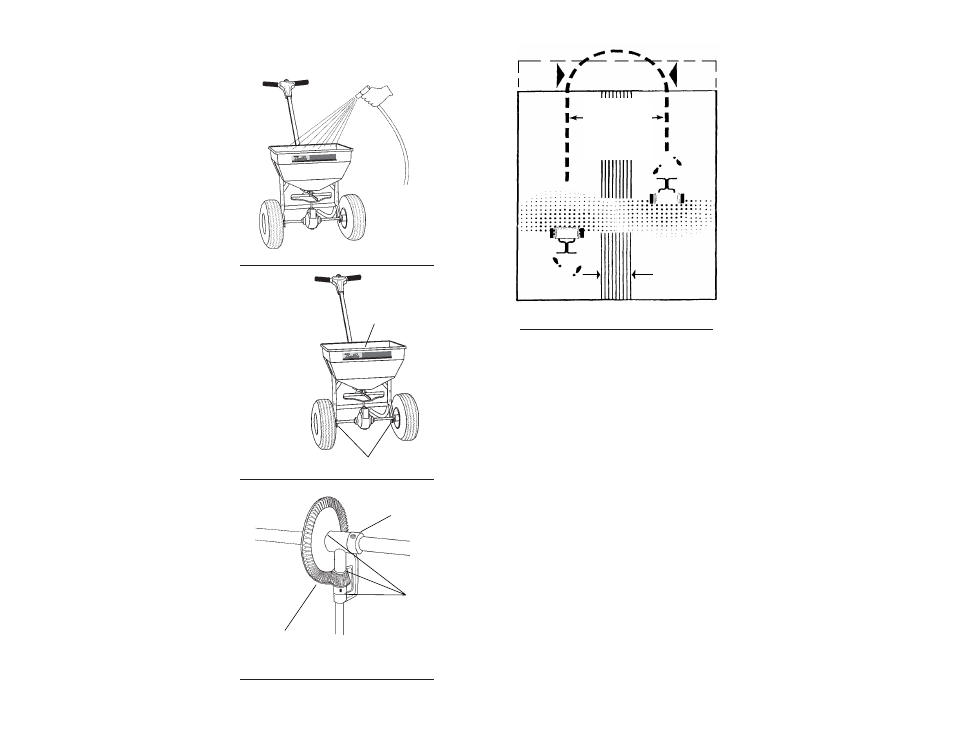

6. Where appropriate, apply header

strips around the area to be treated,

then push the spreader at a walking

speed about 2 1/2 mph (18 feet in

five seconds). To decrease the

spread width in confined areas,

reduce walking speed. Space your

trips across the area as shown in

Figure 10.

7. When transporting the spreader,

make sure the control knob is

pushed in and locked.

8. Empty the spreader after each use,

and return leftover material to its

original container.

Figure 10

Operation

Effective swath

width approximately

10-12 feet on center.

Overlap

8

Maintenance

■ Never store unused material in the

spreader. Return unused material

to its original container.

■ Wash the spreader thoroughly after

each use. See Figure 12. Remove

the gear cover and wash the gears

thoroughly. Then dry completely in

the sun or a heated area.

■ Lubrication

■ Gear mesh should be checked

regularly, especially during high-

use periods. The clearance between

the axle gear and the pinion gear

should be very close, but not tight.

If adjustment is required:

■ Periodically clean the surface of the

impeller to remove buildup of

material. A buildup could cause the

spread pattern to change.

■ Maintain tire pressure at 20–25 psi.

Figure 12

Figure 13

Oil bearing in

the hopper

Oil

Axle

Collar

Oil

Dry Graphite

Oil Control knob and

wire, shut-off plate,

and control plate

spring

Figure 14

a. Lubricate the face of the gear

teeth with dry graphite.

Reinstall the gear cover.

b. Lightly oil the axle bearings in

the frame. See Figure 13.

c. Apply oil to the impeller shaft

bearing in the hopper, pivot

points on the shut-off plate,

and the spring in the housing

behind the control plate.

See Figure 13.

a. Loosen the axle collar set screw

and hold the gears together.

b. Hold the axle gear lightly

against the gear support and

tighten the axle collar set

screw.

c. Spin the drive wheel to make

sure the gears run freely and

smoothly. See Figure 14.

75RS

75RS

TM

75RS

75RS

TM