Lubrication & maintenance – Scag Power Equipment SW User Manual

Page 18

14

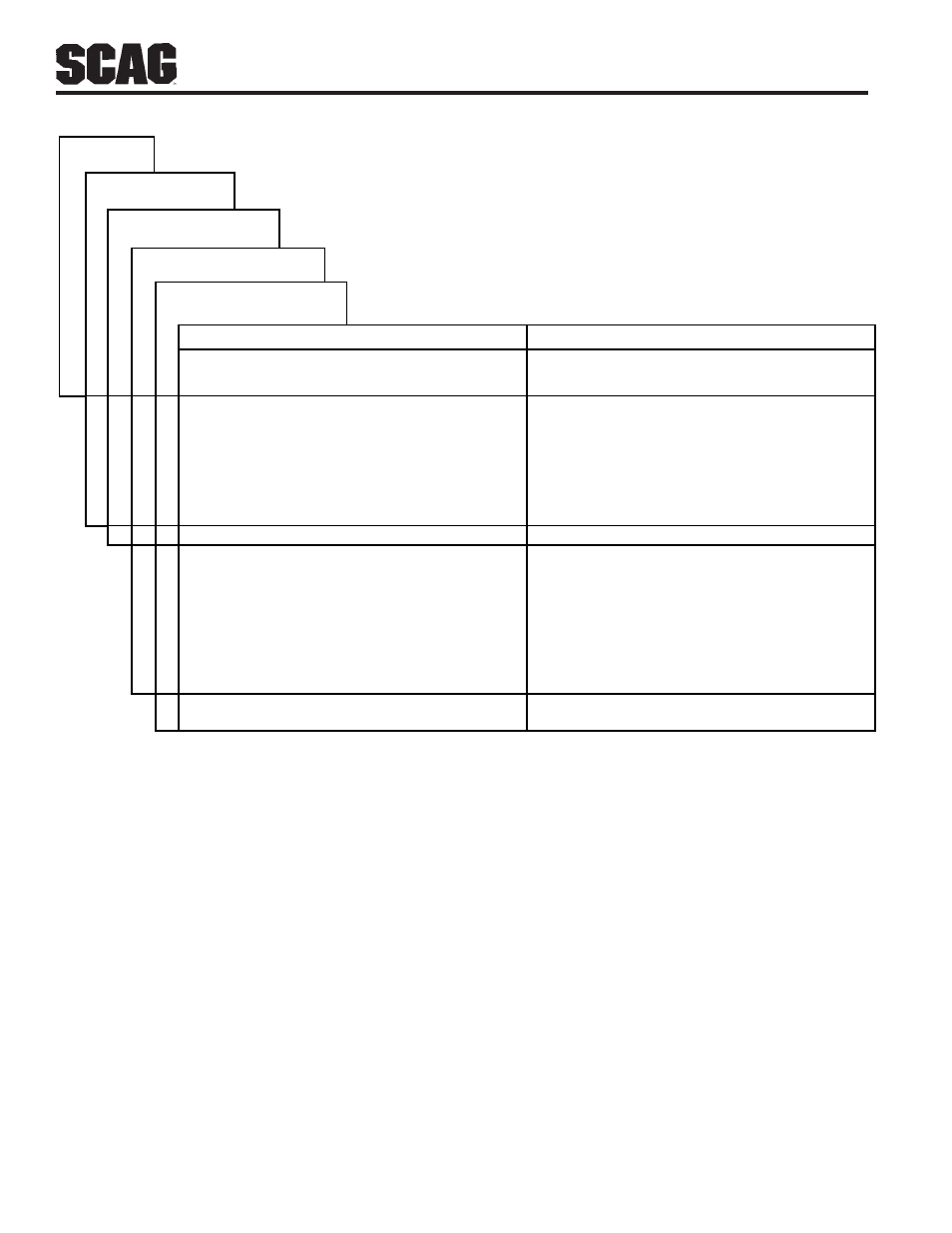

COMMENTS

LUBRICATION & MAINTENANCE

+ Grease spindle until grease comes out the relief valve.

Compatible Greases:

Lidok EP #2 (found at industrial shops)

Ronex MP (Exxon service stations)

Shell Alvania (Shell service stations)

Mobilux #2 (Mobil service stations)

Super Lub M EP #2 (Conoco service stations)

X

X

making this adjustment

PROCEDURE

BREAK-IN

8 HOURS (DAILY)

40 HOURS (WEEKLY)

100 HOURS (BIWEEKLY)

500 HRS OR ANNUALLY

Check all hardware for proper tightness

Change engine oil and filter at 5 hours

X

Check engine oil

Do not over fill

X

Remove debris from under belt cover

More often if needed

X

Sharpen cutter blades

More often if needed

X

Grease spindle bearings

+ US Lithium MP White Grease 2125

X

Clean air filter

More often if needed

X

Check belt tension

X

Check tire pressure

Add or adjust as required

X

Change engine oil

See engine mfg. information

X

Replace air filter

More often if needed

X

Grease caster wheel bearings

Chassis grease

X

Grease caster wheel pivot shafts

Chassis grease

X

Grease idler pulley bracket on cutter deck

Chassis grease

X

Grease drive wheel bearings

Chassis grease

X

Grease transmission couplers

Chassis grease

X

Grease idler bracket LH & RH

Chassis grease

X

Check all hardware for proper tightness

More often if needed

X

Adjust air gap on electric clutch

Contact your Scag dealer for information about