Assembly – Shindaiwa X7501970601 User Manual

Page 8

8

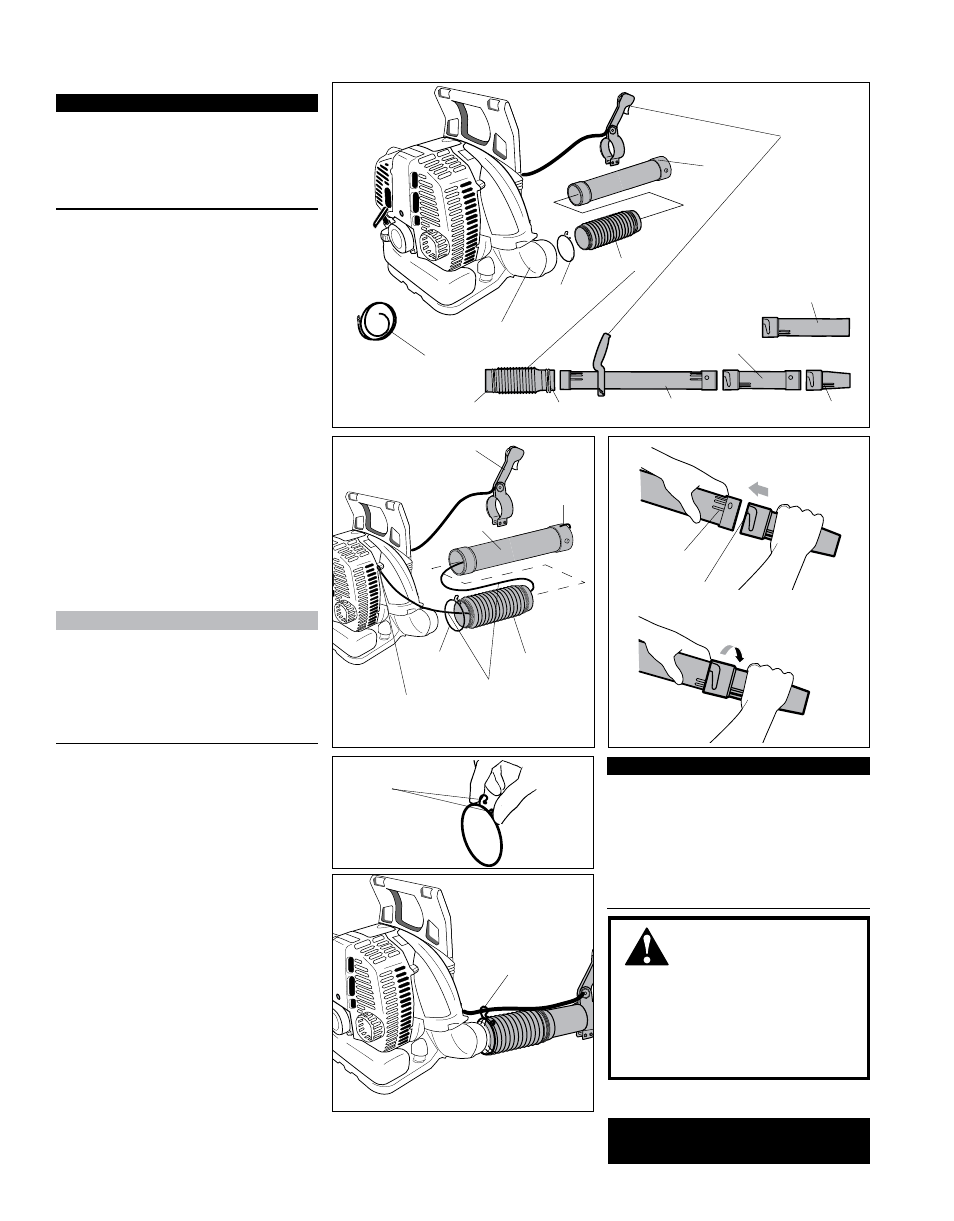

Assembly

IMPORTANT!

Blower tube installation affects blower

performance! Make sure the tubes and

nozzle are correctly assembled per

above, and that all connections are

tight. Blower tubes may come apart dur-

ing use unless tubes are aligned and

locked into place.

Place the blower upright on the

1.

ground or a sturdy work surface and

note parts orientation as shown in

Figure 7.

Remove static wire from package

2.

and fix eyelet to right hand engine

cover screw. See Figure 8.

Turn the discharge tube out to a

3.

right angle and slip anti-static wire

through the 102mm clamp and flex-

ible tube.

Install throttle cable holder just for-

4.

ward of the 102 mm clamp, pinching

loops together to fit over end of flex-

ible tube. See Figures 10A and 10B.

Slip the flexible tube over the end of

5.

the 90° discharge tube, and secure

with the 102 mm clamp.

Slide the throttle assembly over the

6.

swivel tube. Do not tighten clamp at

this time.

Insert the static wire through the

7.

swivel tube, then install and tighten

the 89mm clamp over the rotating

band on the swivel tube.

Fold the end of the static wire back

8.

over the connection of the swivel

tube. See Figure 8.

Grasp the straight tube, and push

9.

the straight tube over the swivel

tube locking pins securing the static

wire. See Figure 9.

Lock the straight tube to the swivel

10.

tube by rotating the straight tube

noting the alignment marks. See

Figure 9.

Grasp the nozzle, and push the

11.

nozzle over the straight tube locking

pins. See Figure 9.

Lock the nozzle to the straight tube

12.

by rotating the nozzle noting the

alignment marks. See Figure 9.

WARNING!

Danger from rotating

impeller!

Stop the engine before installing or

removing the blower tubes! Never

perform any maintenance or assem-

bly procedures on this unit while the

engine is running!

IMPORTANT!

This unit is equipped with a static

discharge reduction wire. This wire

helps direct static buildup into the air

stream reducing the felt amount to the

operator.

NOTE:

Check to make sure that the 90° dis-

charge tube swivels freely. If any

binding is present, loosen 102 mm

clamp and pull wire towards engine to

get more slack and recheck for free

movement.

The blower should now be ready

for use.

Assembling the EB854RT

Figure 7

Flexible Tube

Throttle

Assembly

89mm Clamp

102mm Clamp

Swivel Tube

Straight Tube

Swivel

Tube

90° Discharge

Tube

Anti-Static

Wire

Throttle Cable

Holder

Static Wire

Connector

Static Wire

Fold Wire

Flexible Tube

Swivel

Tube

Throttle

Assembly

Throttle

Cable Holder

Lock Pin

Lock Slot

Rotate clockwise to lock

making sure the 3 lines are

aligned on both tubes.

Align the lock pins with the

lock slots, and push the

tubes together.

Figure 9

Figure 8

Adjust throttle assembly for best

13.

operator comfort, and tighten two

socket-head screws securely.

Loops

Figure 10A

Figure 10B

Throttle

Cable

Holder

Standard Nozzle

(ø65 mm)

Optional

Long Nozzle

(ø74 mm)