Maintenance (continued) – Shindaiwa X7501970601 User Manual

Page 15

15

Fuel Tank

Fuel

Filter

Hooked

Wire

Figure 21

INSPECTION Inspect the entire

■

blower and tubes for damage,

including loose or missing compo-

nents, and repair as necessary.

SPARK PLUG Replace the spark

■

plug with a NGK CMR5H (or equiva-

lent), gapped to 0.6 mm (0.024”).

FUEL FILTER Use a hooked wire to

■

extract the fuel filter from inside the

fuel tank. See Figure 21.

(more frequently if reduced perfor-

mance is noted)

Inspect the filter element for signs

■

of contamination from debris. A

contaminated fuel filter should be

replaced with a new Shindaiwa

replacement element. Before rein-

stalling the filter, inspect the con-

dition of the fuel line. If you note

damage or deterioration, the blower

should be removed from service

until it can be inspected by a Shin-

daiwa-trained service technician.

COOLING SYSTEM Use a wood

■

or plastic scraper and a soft brush

to remove dirt and debris from the

cylinder fins and crankcase.

Every 50 Hours

CAUTION!

Make sure you do not pierce the fuel

line with the end of the hooked wire.

The line is delicate and can be dam-

aged easily.

Maintenance (continued)

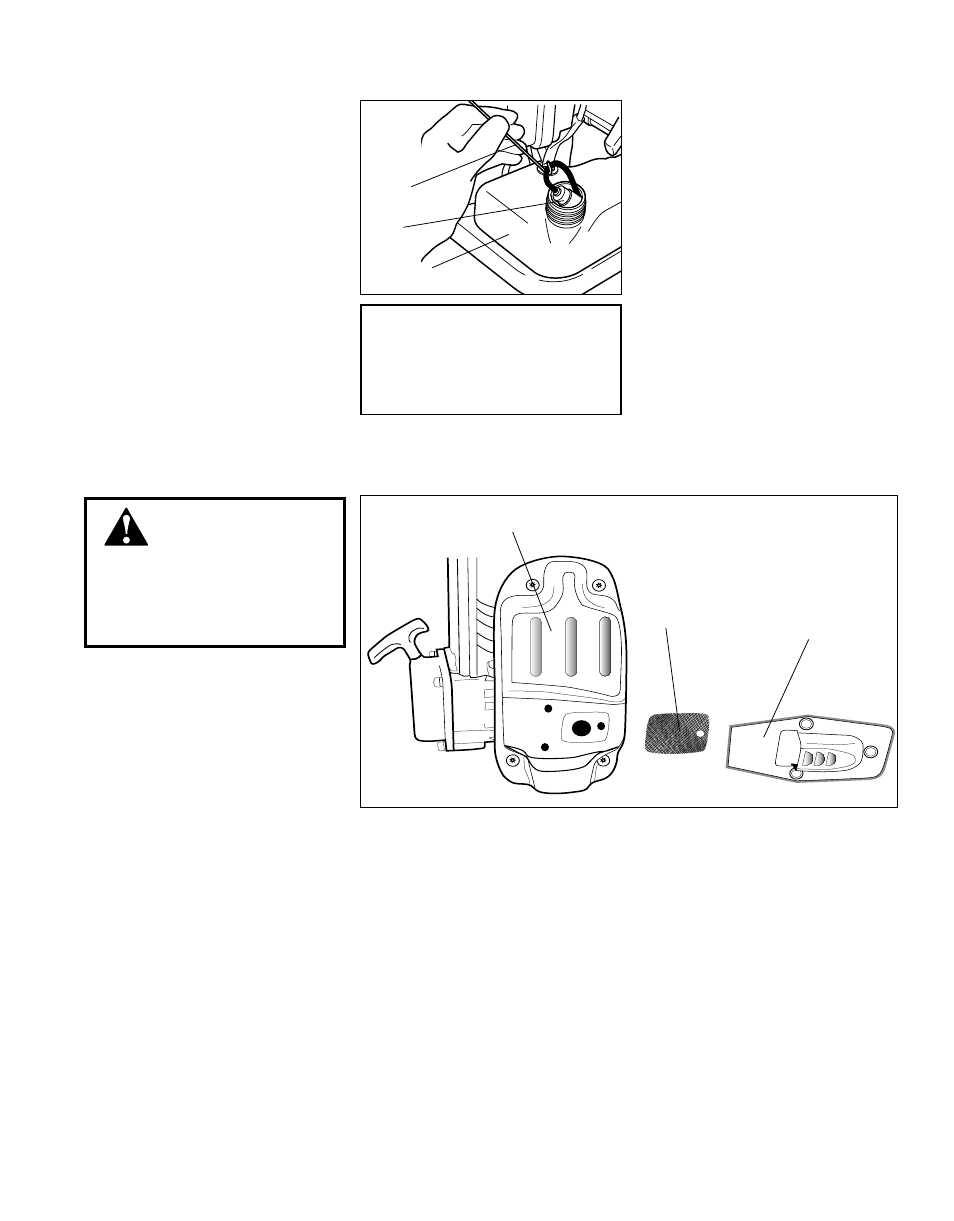

Muffler

Arrester

Screen

Arrester Screen Cover

Figure 22

Inspect the screen carefully, and

3.

replace any screen that has been

perforated, distorted, or is otherwise

unserviceable.

Press the spark arrester into the

4.

exhaust base.

If carbon accumulation in the muffler

or cylinder is severe, or if you do not

notice an improvement in performance

after servicing, have the unit inspected

by an authorized servicing Shindaiwa

dealer.

Spark Arrester

Hard starting or a gradual loss of per-

formance can be caused by carbon

deposits lodged in the spark arrester

screen. For maximum performance, the

spark arrester screen should be periodi-

cally cleaned as follows:

Remove engine cover to expose

1.

muffler. Remove the spark arrester

from the muffler. The arrester is

press-fit in place; there are three

screws to remove.

Use a plastic scraper or wire brush

2.

to remove carbon deposits from

the arrester screen and wipe clean

exhaust base.

WARNING!

Never operate this blower

with a damaged or missing muffler

or spark arrester! Operating with

missing or damaged exhaust compo-

nents is a fire hazard, and can also

damage your hearing!

Maintenance (continued)